Engineering and Technology

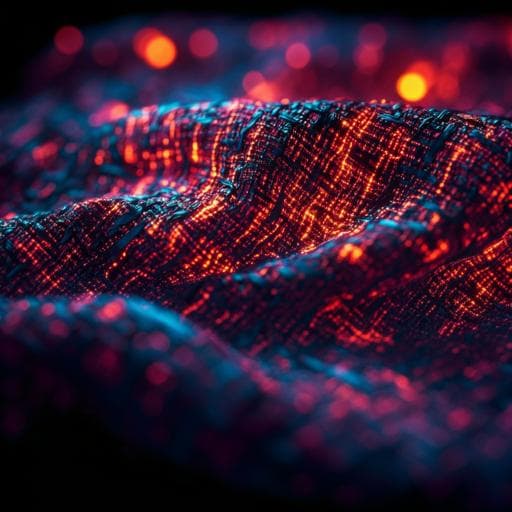

Foldable and washable textile-based OLEDs with a multi-functional near-room-temperature encapsulation layer for smart e-textiles

S. Y. Jeong, H. R. Shim, et al.

This groundbreaking study showcases the development of textile-based OLEDs that not only withstand bending and immersion in water but also exhibit remarkable mechanical durability and washability. The innovative use of a TiO₂ film and hydrophobic polymer for near-room-temperature encapsulation highlights the immense potential of these devices for smart e-textiles, as crafted by a team of dedicated researchers from KAIST and beyond.

Related Publications

Explore these studies to deepen your understanding of the subject.