Food Science and Technology

Effects of gelatin type and concentration on the preparation and properties of freeze-dried fish oil powders

M. Yang, J. Peng, et al.

Gelatin, derived from various animal tissues and sources, exhibits source- and extraction-dependent functional behaviors, motivating evaluation of how gelatin type influences gelatin-based product performance. Fish oil provides health benefits but suffers from fishy odor, poor water solubility, and oxidative instability, leading to interest in encapsulation technologies to improve handling and stability. Complex coacervation using gelatin as a wall material is widely applied for oil encapsulation, yet reported encapsulation efficiencies often remain below 90%. The authors previously achieved high encapsulation efficiency (>95.2%) by combining gelatin–sodium hexametaphosphate (SHMP) complex coacervation with SSOS-aided freeze-drying. The present study aims to clarify how gelatin type (PSG, BSG, FG, CFG) and concentration affect formation of coacervates and the resulting fish oil powder properties (morphology, physicochemical metrics, oxidative stability), as well as their behavior under acidic/neutral conditions and in an in vitro gastrointestinal model. This work addresses the knowledge gap on structure–function relationships of different gelatins in solid fish oil encapsulates and informs formulation choices for improved stability and digestion.

The paper reviews oil encapsulation methods including complex coacervation, spray-drying, freeze-drying, and electrospraying. Prior complex coacervation studies used gelatin with acacia gum, SHMP, gum Arabic, or almond gum, typically yielding encapsulation efficiencies below 90%. The authors’ earlier work combined gelatin–SHMP coacervation with SSOS during freeze-drying, achieving >95.2% encapsulation efficiency in fish oil powders. Literature cited also compares properties of gelatins from various sources (mammalian vs fish), highlighting differences in isoelectric points, molecular weights, and gelling properties that may influence emulsion stabilization and coacervation behavior, and underscores the need to understand how these properties affect encapsulation performance and oxidative stability.

Materials and formulation: Four type A gelatins were used—porcine skin (PSG), bovine skin (BSG), fish (FG, tilapia), and commercial cold-water fish skin gelatin (CFG). Gelatin solutions at 60, 80, or 100 mg/mL were prepared by dispersing 6, 8, or 10 g gelatin in 100 mL water, swelling 30 min, then dissolving at 45 °C for 1 h. Emulsion preparation: After cooling to room temperature, 8 g fish oil was added to each gelatin solution and homogenized at 8000 rpm for 5 min (T25 ULTRA-TURRAX). Emulsions were observed by optical microscopy. Complex coacervation: Emulsions were mixed with 100 mL SHMP solution at 50 °C, 400 rpm for 1 min at a fixed SHMP:gelatin mass ratio of 1:15. pH was carefully adjusted (with 1 mol/L H3PO4 or NaOH) at 50 °C to induce coacervation; target pH for coacervate formation was around 4.7 (PSG), 4.4 (BSG), and 4.8 (FG). CFG conditions were screened (pH 4.5–4.7; SHMP:gelatin 1:10–1:20; gelatin 60–100 mg/mL). Samples were rested at room temperature. Freeze-drying and SSOS aid: After coacervation, 8 g SSOS was added, mixed at 400 rpm for 30 min, then freeze-dried at −50 °C for 48 h (lyophilizer FD-1C-50). Dried cakes were gently crushed to powders. Parallel samples without SSOS were also prepared. SEM (Hitachi S-3400, 10 kV) was used to observe microstructures. Protein characterization: Gelatin molecular weight distributions were assessed by SDS-PAGE (2 mg/mL gelatin; 8% Bis-Tris gels; 120 V, 80 min; Coomassie staining/destaining). ATR-FTIR (PerkinElmer Spotlight 400) examined amide band positions to infer hydrogen bonding. Gel strength (Bloom) was measured per British Standard 757:1975 by preparing gels (7.5 g gelatin/105 mL water), dissolving at 65 °C, and setting at 10 °C for 16 h. Powder physicochemical properties: Bulk and tapped densities were determined using a 50 mL graduated cylinder before and after manual tapping. Moisture content was determined by oven drying at 105 °C to constant mass; water activity was measured with AquaLab 4TE. Encapsulation metrics: Surface oil was quantified by hexane washing/evaporation; total oil by acid disruption (HCl 4 mol/L) with hexane extraction followed by evaporation; both dried at 105 °C to constant mass. From these, loading capacity (LC), encapsulation efficiency (EE), surface oil content, and encapsulation yield (EY) were calculated. Oxidative stability: Schaal oven tests evaluated peroxide values over 0–72 h at 63 °C and 70% RH (Chinese National Standard 5009.227-2016). Peroxide values were determined by iodometric titration and expressed as meq/Kg oil, accounting for LC. Stability at acidic/neutral pH: Powders (0.1 g) were incubated in PBS at pH 2.0 or 7.0 for 2 h at room temperature; suspensions and particles were observed by camera and microscopy. In vitro digestion: A two-stage gastrointestinal model was used: 0.1 g powder in gastric phase at 37 °C, pH 2.0 for 2 h; then intestinal phase for 2 h with pH maintained by 0.5 mol/L NaOH. Free fatty acid (FFA) release was quantified by titration and expressed as percent of theoretical based on LC and triacylglycerol stoichiometry. Statistics: Experiments were performed in triplicate; data are mean ± SD. One-way ANOVA assessed differences with p < 0.05.

- CFG failed to form stable gelatin–SHMP complex coacervates necessary for powder production across tested pH (4.5–4.7), SHMP:gelatin ratios (1:10–1:20), and concentrations (60–100 mg/mL). CFG coacervates floated/aggregated and lacked stability. Likely causes: unobvious isoelectric point, significantly lower molecular weight (<30 kDa band), more hydrogen bonding (FTIR amide A and II shifts), and longer gel formation time (no gel at 10 °C after 16 h), compared with PSG/BSG/FG.

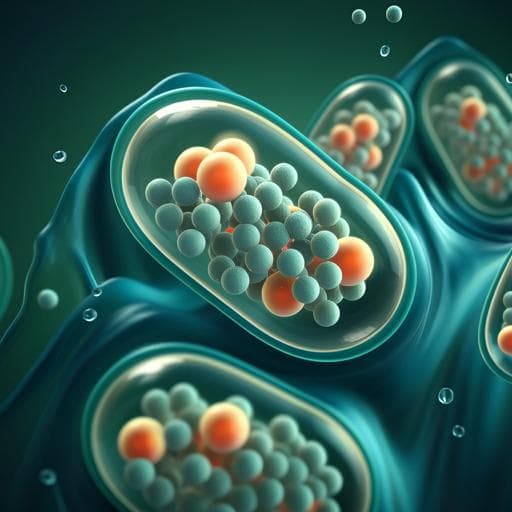

- PSG, BSG, and FG formed coacervates at 60–100 mg/mL; higher gelatin concentration yielded smaller coacervate sizes. Coacervates were aggregates of emulsion droplets formed via electrostatic interactions between positive gelatin and negative SHMP at the droplet interface and aqueous phase.

- SEM of freeze-dried powders (with or without SSOS) showed typical freeze-drying porous channels and two particle types: rough, protruded oil-loaded particles (core–shell structures) and smooth, oil-unloaded particles. Gelatin type and concentration did not markedly affect morphology. SSOS increased coacervate stability during freeze-drying, leading to larger spherical protrusions than samples without SSOS.

- Bulk/tapped densities depended on gelatin type and concentration. For PSG and BSG powders, densities increased (implying smaller particle sizes) with higher gelatin concentration; FG did not follow this trend. The 80 mg/mL formulations often had the highest densities.

- Moisture and water activity depended on gelatin type and concentration. BSG-based powders had the highest moisture content; PSG at 100 mg/mL exhibited the highest water activity.

- Encapsulation performance: All SSOS-aided powders generally showed high EE (>95%) and low surface oil (<5%), except BSG at 100 mg/mL which had reduced EE and elevated surface oil, indicating suboptimal encapsulation at this condition. LC for PSG/BSG was relatively insensitive to concentration; FG LC decreased with higher gelatin concentration. EY decreased with increasing PSG and FG concentration; BSG peaked at ~79.01% EY at 80 mg/mL.

- Oxidative stability (Schaal test, 63 °C, up to 72 h): Peroxide values increased to a maximum at ~3 h then decreased, indicating conversion of primary to secondary oxidation products. Peak peroxide values were governed by gelatin type, not concentration: PSG (153 ± 5–168 ± 3 meq/Kg oil) < BSG (176 ± 5–188 ± 1 meq/Kg oil) < FG (196 ± 11–201 ± 22 meq/Kg oil). Values compared favorably to calcium alginate capsules, suggesting better storage performance of freeze-dried gelatin powders.

- Stability in PBS (pH 2.0 or 7.0): After 2 h, substantial precipitates persisted; microscopy indicated particles similar to untreated powders. SSOS likely dissolved, leaving insoluble gelatin–SHMP coacervates. Thus, acidic/neutral PBS did not dissolve coacervates and is not suitable to assess digestion.

- In vitro gastrointestinal behavior: In gastric phase, SSOS-containing powders fully dissolved in ~5 min to form emulsion droplets, whereas powders without SSOS dissolved in ~20 min. In intestinal phase, incomplete digestion was evidenced by residual droplets and FFA release values below 100%. SSOS significantly increased FFA release versus no-SSOS, indicating promotion of coacervate-to-emulsion transformation and emulsion breakdown.

- Gelatin effects on FFA release (with SSOS): PSG showed decreasing FFA release with higher concentration; BSG peaked at 60 mg/mL; FG showed increasing FFA release with higher concentration. Trends did not align simply with particle size or standard physicochemical metrics, implying gelatin-specific interactions govern digestion outcomes.

The study demonstrates that gelatin source critically determines complex coacervation feasibility and powder performance. CFG’s lack of a clear isoelectric point, low molecular weight, higher intramolecular/intermolecular hydrogen bonding, and slow gelation hindered formation of stable coacervates, precluding its use under tested conditions. In contrast, PSG, BSG, and FG formed robust coacervates that, with SSOS-assisted freeze-drying, yielded powders of similar micro-morphology but differing physicochemical properties and oxidative stability. Gelatin type controlled bulk/tapped density trends, moisture/aw, and particularly oxidative behavior, with PSG conferring the best oxidative protection and FG the least among the three. Encapsulation was generally high-efficiency across types, though excessive BSG concentration (100 mg/mL) degraded EE and increased surface oil, underscoring the importance of optimizing polymer concentration for effective core encapsulation. The gastrointestinal simulations revealed that SSOS plays a dual role: stabilizing coacervates during drying and facilitating rapid dissolution and oil digestion, leading to greater FFA release. Gelatin type and concentration modulated lipolysis patterns in ways not directly predicted by bulk metrics, indicating that protein–lipid–polyanion interactions and interfacial properties unique to each gelatin likely dominate digestion behavior. Collectively, these findings address the central question by mapping how gelatin identity and amount steer coacervate formation, powder quality, oxidative resistance, and digestive fate, informing rational selection of gelatin systems for fish oil solid encapsulation.

This work systematically evaluates how gelatin type (PSG, BSG, FG, CFG) and concentration (60–100 mg/mL) influence formation of gelatin–SHMP complex coacervates, SSOS-aided freeze-dried fish oil powders, and their properties. CFG could not produce stable coacervates, attributed to its low molecular weight, stronger hydrogen bonding, lack of a clear pI, and slow gelation. PSG, BSG, and FG yielded powders with high encapsulation efficiency (>95% in most cases), distinct density/moisture profiles, and gelatin-dependent oxidative stability, with PSG providing the lowest peroxide values. SSOS improved drying integrity and promoted rapid dissolution and higher lipolysis in an in vitro GI model. These insights guide formulation strategies for stable, digestible fish oil encapsulates. Future work should examine broader gelatin sources (animal/tissue origins and extraction methods) to refine structure–function relationships, decouple particle size effects by preparing powders with controlled, matched sizes, and investigate gelatin–SHMP coacervation mechanisms without oil to deepen understanding of complex formation dynamics.

- CFG assessment indicates failure to form stable coacervates under the tested pH, ratio, and concentration ranges; alternative conditions or modifications were not explored.

- Mechanistic explanations for certain observations (e.g., elevated water activity in PSG at 100 mg/mL, low EE/high surface oil in BSG at 100 mg/mL) remain speculative and require further study.

- Stability testing focused on peroxide values under accelerated Schaal conditions; long-term storage at varied temperatures/humidities and secondary oxidation products were not comprehensively evaluated.

- PBS at pH 2 and 7 proved unsuitable to model digestion; although an in vitro GI model was used, in vivo relevance requires validation.

- Only three gelatins (PSG, BSG, FG) produced functional powders; generalizability to other gelatins, modifications, or crosslinked systems remains to be established.

Related Publications

Explore these studies to deepen your understanding of the subject.