Chemistry

Controlled self-assembly of plant proteins into high-performance multifunctional nanostructured films

A. Kamada, M. Rodriguez-garcia, et al.

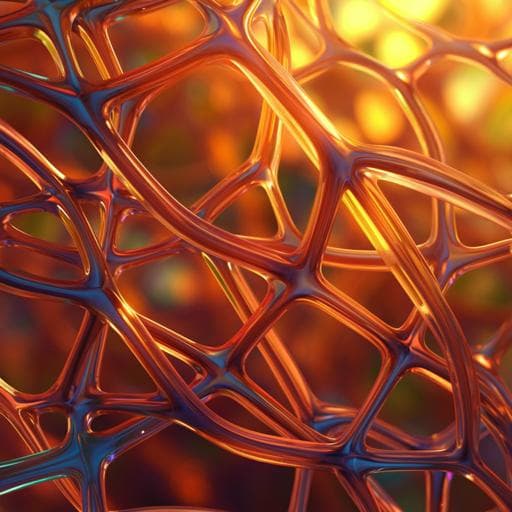

This research showcases an innovative and scalable technique for producing strong, plant-based films through controlled self-assembly of water-insoluble proteins, achieving mechanical properties rivaling engineering plastics and impressive optical transmittance. The work, conducted by Ayaka Kamada, Marc Rodriguez-Garcia, Francesco Simone Ruggeri, Yi Shen, Aviad Levin, and Tuomas P. J. Knowles, also explores micro-patterning to create hydrophobic surfaces and vibrant structural color.

~3 min • Beginner • English

Related Publications

Explore these studies to deepen your understanding of the subject.