Engineering and Technology

Bottom-up construction of low-dimensional perovskite thick films for high-performance X-ray detection and imaging

S. Dong, Z. Fan, et al.

X-ray detection underpins medical imaging, industrial inspection, and scientific research. Metal halide perovskites are promising X-ray detector materials due to strong X-ray stopping power, large mobility–lifetime products, tunable bandgaps, and low free-carrier densities. While 3D perovskite detectors can achieve very high sensitivities (>10⁵ µC Gyair⁻¹ cm⁻²) and low detection limits (~1 nGyair s⁻¹), ion migration compromises long-term stability and hinders commercialization. Introducing long-chain spacer cations to form low-dimensional (especially quasi-2D) perovskite quantum-well structures suppresses ion migration and improves stability, with properties tunable by spacer choice and well thickness. For efficient X-ray absorption, thick perovskite layers (hundreds of micrometers) are required, but conventional spin- or blade-coating of precursor solutions typically yields films <10 µm and suffers from surface-first crystallization that traps solvent, producing voids and cracks upon annealing. There is a need for a new growth strategy enabling thick, dense, uniform Q-2D perovskite films directly on large-area substrates for high-performance detectors and imagers.

Prior work established perovskites as competitive X-ray detector materials, with 3D perovskites demonstrating exceptional sensitivity and low detection limits but facing instability from ion migration. Strategies using low-dimensional perovskites with spacer cations mitigate ion migration via quantum-well effects and improved structural robustness. Standard solution methods (spin-coating, blade-coating) are simple but limited in achievable thickness and film integrity due to premature surface crystallization and solvent-trapping defects in thick films. Thus, literature highlights a trade-off between performance and stability, and a gap in scalable methods for high-quality, thick perovskite layers compatible with flat-panel device architectures.

- Materials and precursor: Prepared a high-solid-content liquid quasi-2D perovskite BA₂MA₉Pb₁₀I₁₃·xCH₃NH₂ via solid–liquid conversion using CH₃NH₂ gas intercalation. Added acetonitrile (ACN) to tune rheology for blade-coating.

- Film deposition and atmosphere-assisted crystallization: Blade-coated the liquid perovskite onto substrates to form wet films. Compared conventional direct annealing versus atmosphere-assisted annealing. Employed controlled atmospheres: CH₃NH₂, NH₃, and mixed CH₃NH₂/NH₃, within a semi-enclosed environment to allow gradual release of CH₃NH₂ and solvent during thermal annealing. Rationale: CH₃NH₂ near-saturates the surface to inhibit surface nucleation, enabling bottom-up crystallization; NH₃ slows crystallization and can form a transient NH₄PbI₃ intermediate; a mixed CH₃NH₂/NH₃ atmosphere balances delayed nucleation with bottom-up growth, yielding dense, large-grained films. Film thickness was tuned from tens to hundreds of micrometers by adjusting precursor volume and atmosphere.

- Large-area films: Demonstrated 5 × 5 cm² films on quartz, showing improved uniformity with the mixed-gas regimen.

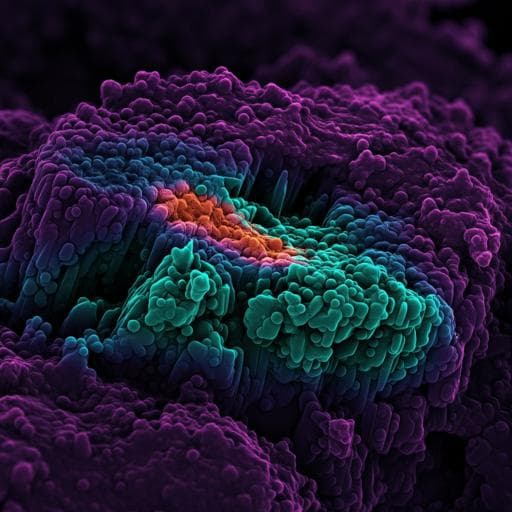

- Structural and optical characterization: SEM for surface/cross-section morphology; XRD to assess phase/crystallinity and to identify/removal of NH₄PbI₃ intermediate (present under NH₃-rich growth, absent after mixed-atmosphere annealing); steady-state PL for film quality; UV–vis absorption and Tauc analysis to determine bandgap (~1.59 eV, ~790 nm edge).

- Electrical characterization: Measured bulk resistivity via I–V on thick films; extracted ion migration activation energy (Eₐ) from temperature-dependent conductivity; determined μτ by photoconductivity measurements fitted with the modified Hecht equation; measured carrier mobility via time-of-flight (TOF) transients under varied electric fields; evaluated dark and illuminated surface potentials by KPFM/CPD mapping.

- Device architecture: Fabricated heterojunction X-ray detectors by integrating a TiO₂ electron-transport layer on ITO substrates beneath the Q-2D perovskite to form ITO/TiO₂/BA₂MA₉Pb₁₀I₁₃ stacks; compared to ITO/BA₂MA₉Pb₁₀I₁₃ devices without TiO₂. Assessed diode rectification and dark current suppression from I–V characteristics; built flat-panel X-ray imagers (FPXIs).

- Radiation interaction modeling: Computed/compared X-ray attenuation efficiencies across BA₂MA₉Pb₁₀I₁₃, CZT, Si, MAPbBr₃, MAPbI₃ over 0.01–10 MeV; analyzed 40 keV attenuation versus thickness.

- X-ray detection metrics: Quantified sensitivity versus dose rate (70–2726 nGyair s⁻¹) under different electric fields; determined detection limits via SNR versus dose rate; evaluated spatial resolution via MTF and line-pair analysis; demonstrated imaging at low doses.

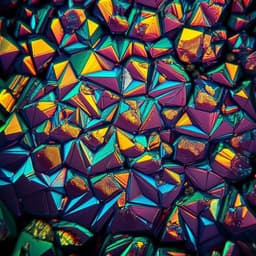

- Atmosphere-assisted growth: Mixed CH₃NH₂/NH₃ atmosphere enabled bottom-up crystallization, producing dense, crack-free Q-2D BA₂MA₉Pb₁₀I₁₃ films with controllable thickness from tens to hundreds of micrometers and good uniformity on 5 × 5 cm² substrates (SEM/PL evidence).

- Phase control: NH₃-rich growth formed an NH₄PbI₃ intermediate (XRD), while mixed-gas processing eliminated NH₄PbI₃ after annealing, yielding higher crystallinity and larger grains.

- Bandgap: All films exhibited an absorption edge ~790 nm with Eg ≈ 1.59 eV (Tauc), suitable for room-temperature X-ray detection.

- Electrical properties: Bulk resistivity increased from 1.80 × 10⁷ Ω·cm (control) to 8.65 × 10⁷ Ω·cm (CH₃NH₂) and 2.48 × 10⁸ Ω·cm (CH₃NH₂/NH₃). Ion migration activation energy Eₐ rose to 0.632 eV (mixed atmosphere), higher than CH₃NH₂ (0.589 eV), control (0.365 eV), and MAPbI₃ (0.301 eV). μτₑ reached 7.81 × 10⁻⁵ cm² V⁻¹, exceeding commercial α-Se (~10⁻⁷ cm² V⁻¹). Carrier mobility (TOF) improved to 19.3 cm² V⁻¹ s⁻¹ (mixed) vs 18.1 cm² V⁻¹ s⁻¹ (CH₃NH₂).

- Attenuation: BA₂MA₉Pb₁₀I₁₃ showed X-ray attenuation comparable to CZT and 3D perovskites and superior to Si at 40 keV for a given thickness.

- Heterojunction benefits: Incorporating TiO₂ produced strong rectification, reducing dark current density by hundreds of times under negative bias and improving charge extraction (KPFM CPD contrast under illumination).

- Detector performance: Achieved ultrahigh X-ray sensitivity of 29721.4 µC Gyair⁻¹ cm⁻² and a low detection limit of 20.9 nGyair s⁻¹. SNR followed ~√dose behavior; devices with TiO₂ outperformed those without.

- Imaging: Flat-panel X-ray imager delivered clear images at low dose with spatial resolution of 3.6 lp mm⁻¹ at MTF = 0.2 (0.72 lp pix⁻¹), among the highest reported for perovskite FPXIs.

Controlling crystallization with a mixed CH₃NH₂/NH₃ atmosphere addresses the dual challenges of achieving thick perovskite layers and maintaining film integrity. Suppressing surface nucleation (via CH₃NH₂) and moderating growth (via NH₃ and a transient NH₄PbI₃ intermediate) promotes bottom-up crystallization, enabling efficient solvent release and yielding dense, large-grained Q-2D films. These morphological improvements directly enhance bulk resistivity and reduce defect-assisted leakage, lowering detector noise. The increased ion migration activation energy in Q-2D films, further boosted by mixed-atmosphere processing, mitigates ionic drift, allowing application of larger biases to extend carrier drift lengths and improve collection efficiency. The improved μτ and mobility corroborate enhanced transport, translating to very high sensitivity and low detection limits. Forming a TiO₂/perovskite heterojunction further suppresses dark current and facilitates selective carrier extraction, which is crucial for low-dose detection. The combination of thick, high-quality Q-2D absorbers with an optimized heterojunction yields detector and FPXI performance that rivals or surpasses state-of-the-art perovskite systems, achieving high spatial resolution at low dose, and demonstrating the practical viability of this bottom-up construction strategy for scalable X-ray imaging applications.

The study introduces an atmosphere-assisted bottom-up crystallization strategy for Q-2D BA₂MA₉Pb₁₀I₁₃ thick films using a mixed CH₃NH₂/NH₃ environment. This approach yields dense, crack-free films hundreds of micrometers thick with enhanced crystallinity, higher resistivity, and suppressed ion migration. Integrating a TiO₂ electron-transport layer to form a heterojunction detector drastically reduces dark current and boosts charge extraction, enabling ultrahigh sensitivity (29721.4 µC Gyair⁻¹ cm⁻²), a low detection limit (20.9 nGyair s⁻¹), and high-resolution FPXI imaging (3.6 lp mm⁻¹ at MTF 0.2). These results advance low-dimensional perovskite X-ray detection and imaging toward practical deployment. Potential future work includes optimizing gas composition and annealing dynamics for broader perovskite chemistries, scaling uniform film growth on TFT backplanes, assessing long-term operational and radiation stability, and exploring alternative transport layers and device architectures for further noise reduction and resolution enhancement.

Related Publications

Explore these studies to deepen your understanding of the subject.