Chemistry

Bioinspired trimesic acid anchored electrocatalysts with unique static and dynamic compatibility for enhanced water oxidation

X. Lin, Z. Wang, et al.

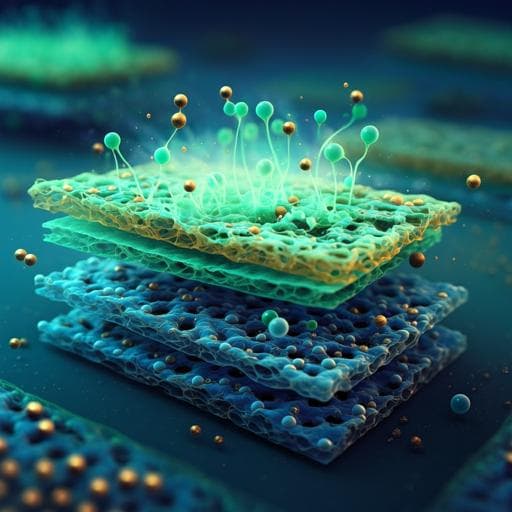

The oxygen evolution reaction (OER) underpins key energy technologies (metal–air batteries, nitrogen and carbon dioxide reduction, and water electrolysis) but commercial Ir- and Ru-based catalysts are scarce and costly. Earth-abundant Ni, Co, and Fe-based electrodes show promise yet fail to meet industrial targets of >1000 h at >1000 mA cm−2 due to kinetic bottlenecks and stability issues. Two-dimensional NiFe layered double hydroxides (NiFe-LDHs) offer favorable lamellar structures and tunable electronics, but face intrinsic scaling constraints among *O, *OH, and *OOH intermediates and suffer metal segregation and dissolution during long-term operation. Inspired by the Mn4Ca cluster in photosystem II, where amino-acid carboxylates stabilize metal centers and mediate concerted proton–electron transfer, this work proposes anchoring carboxylate ligands (trimesic acid) within NiFe-LDHs to simultaneously stabilize active metal sites and accelerate proton transfer. The study aims to elucidate how static coordination (C–O–Fe anchoring) and dynamic evolution of uncoordinated carboxylates improve OER kinetics, bubble management, and long-term durability, particularly at industrial current densities and alkaline conditions.

Prior efforts to enhance NiFe-LDH OER performance include morphology control, vacancy engineering, and doping, which improve activity but struggle to overcome kinetic scaling relations at high current densities. Stability remains challenged by phase/metal segregation and continuous metal leaching under alkaline OER. Bioinspired strategies in homogeneous catalysis demonstrate that carboxylate ligands from amino acids stabilize metal clusters and act as internal bases to facilitate proton transfer via CPET; similar approaches improve stability and activity in Ru complexes for water oxidation. However, the cooperative effects of carboxylate anchoring with multi-metal active sites in heterogeneous catalysts are not fully understood, limiting rational catalyst design.

Catalyst synthesis: NiFe-LDH with trimesic acid ligands was electrodeposited directly onto conductive substrates (carbon paper, carbon cloth, nickel foam). For NiFe-LDH(TA)@cp: electrolyte contained Ni(NO3)2·6H2O (conditioning agent and Ni source), FeSO4·7H2O (Fe2+ source), and trimesic acid (TA) as the ligand; electrodeposition generated both coordinated and uncoordinated carboxylate groups via local pH/redox changes near the electrode. For SU-NiFe-LDH(TA)@cp: Fe(NO3)3·9H2O (Fe3+ source with different dissociation/redox properties) replaced FeSO4·7H2O to tune nanosheet size and roughness. A typical SU-NiFe-LDH(TA) deposition used a three-electrode setup (working: 1×2 cm2 carbon paper, counter: Pt, reference: Ag/AgCl (sat. KCl)), deposition solution of 3 mmol Fe(NO3)3·9H2O, 4.5 mmol Ni(NO3)2·6H2O, 0.6 mmol TA in 20 mL water + 10 mL DMF; constant potential −1.0 V for 1000 s; rinse and dry. Control compositions SU-NixFey-LDH(TAz) were prepared by varying precursor ratios; catalyst loading ~3.0 ± 0.2 mg cm2 over 1×1 cm2 area. Reference NiFe-LDH@cp was similarly deposited without TA (FeSO4 source); NiFe-LDH(TA)@cp included 0.6 mmol TA. Characterization: XRD (phase and crystallinity), SEM/TEM/HR-TEM and SAED (morphology, nanosheet size, lamellae spacing ~0.7 nm for (003) planes), FTIR and Raman (ligand coordination signatures including C–O–Fe modes at 1160 and 850 cm−1; carboxylate νas/νs bands; Ni–OH modes), XPS (Ni 2p, Fe 2p, C 1s, O 1s; deconvolution to identify C–O–Fe species and oxygen vacancy fraction), ICP-MS (dissolved Ni/Fe after electrolysis), contact angle and in situ bubble imaging (3D confocal microscopy) for wettability/aerophobicity and bubble dynamics. Electrochemistry: Three-electrode OER in 1 M KOH with CHI 660E. LSV at 5 mV s−1 with 90% iR compensation (unless noted), Tafel analysis, EIS (10^5–0.01 Hz at 1.48 V vs RHE), double-layer capacitance from CV (1.183–1.233 V vs RHE) to estimate ECSA. Chronoamperometry for stability. Full-cell AWE tests: SU-NiFe-LDH(TA)@nf paired with Pt (HER) or commercial nickel foam (HER) for high current density performance, including industrial conditions (6 M KOH, 60 °C). Operando spectroscopy: In situ Raman (0.30–0.58 V vs Ag/AgCl) to track Ni–OH and carboxylate evolution; in situ FTIR (1–3 V cell voltage window) to observe coordinated (–COO−) and uncoordinated (–COOH) carboxyl bands and OH features during operation. Theory: Spin-polarized DFT (VASP 6.1.0, PBE-GGA, D3 dispersion), plane-wave cutoff 420 eV, k-points 2×2×1 for geometry and 11×11×1 for DOS. CHE model for OER free energies at U = 0 V; Bader charge and differential charge density analyses to assess ligand–LDH electronic interactions; comparison of OER pathways and energetics at Ni and Fe sites in pristine NiFe-LDH vs SU-NiFe-LDH(TA).

- Structure and composition: Trimesic acid ligands successfully anchor to NiFe-LDH via C–O–Fe bonds, evidenced by FTIR bands at 1160 and 850 cm−1 and Fe 2p XPS features assigned to C–O–Fe. Raman shows redshifted Ni–OH modes upon ligand introduction, indicating electronic interaction. SU-NiFe-LDH(TA) forms ultrathin nanosheets with smaller lateral size (~47–57 nm) and rougher surfaces compared with NiFe-LDH(TA) (~734 nm), attributed to Fe3+ use during electrodeposition.

- Increased defect/active sites: O 1s XPS shows a higher oxygen vacancy/low-coordination oxygen fraction in SU-NiFe-LDH(TA) (Ov ~26.43%) vs NiFe-LDH(TA) (16.34%) and NiFe-LDH (16.61%).

- Wettability and bubble dynamics: Contact angles with water: NiFe-LDH@cp 18°, NiFe-LDH(TA)@cp 15°, SU-NiFe-LDH(TA)@cp ~0° (superhydrophilic). In situ bubble imaging at 200 mA cm−2 shows bubble diameter on SU-NiFe-LDH(TA)@cp ~8.54 μm vs 34.67 μm on NiFe-LDH@cp, indicating superaerophobic behavior with rapid bubble detachment.

- OER activity (1 M KOH, three-electrode): Overpotential at 100 mA cm−2: SU-NiFe-LDH(TA)@cp 248 mV, NiFe-LDH(TA)@cp 265 mV, NiFe-LDH@cp 308 mV. Tafel slopes: 31.1 mV dec−1 (SU-NiFe-LDH(TA)@cp), 40.6 mV dec−1 (NiFe-LDH(TA)@cp), 98.4 mV dec−1 (NiFe-LDH@cp). EIS charge-transfer resistance (semicircle radius): SU-NiFe-LDH(TA)@cp 1.69 Ω cm2 (smallest). Double-layer capacitance Cdl: 3.2 mF cm−2 (SU), 1.64 mF cm−2 (TA), 0.81 mF cm−2 (LDH), consistent with higher ECSA. Intrinsic activity normalized to ECSA is highest for SU-NiFe-LDH(TA)@cp.

- Stability and metal dissolution: In 1 M KOH, SU-NiFe-LDH(TA)@cp shows negligible current decay over 150 h at 1.73 V vs RHE; post-test XRD/FTIR/Raman confirm structural retention and persistent coordinated and uncoordinated carboxylate signatures; XPS shows minimal shifts vs pristine, unlike NiFe-LDH which shows increased binding energies and higher Ov (53.23%) indicative of metal dissolution. ICP-MS after 24 h reveals dramatically reduced Ni and Fe leaching for TA-functionalized samples versus bare NiFe-LDH.

- Industrially relevant performance: Full-cell SU-NiFe-LDH(TA)@nf//Pt AWE sustains ~98% of initial 1500 mA cm−2 at 2.18 V for 1300 h. Under industrial conditions (6 M KOH, 60 °C), SU-NiFe-LDH(TA)@nf//nf delivers 1000 mA cm−2 at 1.90 V and maintains activity with no decay for >800 h. Morphology after 1300 h remains ultrathin nanosheets (~45 nm), corroborating robustness.

- Operando mechanistic evidence: In situ Raman shows stable coordinated carboxylate band (~1421 cm−1) acting as static anchors; emergence of broad ~1642 cm−1 (–COOH) indicates uncoordinated carboxyl groups persist under OER. In situ FTIR shows coordinated –COO− bands (1620, 1433 cm−1) and growth of –OH (~3000 cm−1) and antisymmetric –COOH (1608 cm−1), supporting dynamic interconversion and involvement in proton transfer.

- DFT insights: Ligand anchoring strengthens Fe–O interactions; charge density difference and Bader analysis show electron transfer from Fe and TA carbon to bridging O via C–O–Fe, stabilizing metal centers. OER free-energy profiles: For pristine NiFe-LDH, RDS energies at U=0 V are 2.67 eV (*O formation on Ni) and 2.12 eV (*OOH formation on Fe). With TA ligands, RDS becomes OH deprotonation to *O on Ni with reduced energies (2.06 eV at Ni site; 1.94 eV at Fe site). Energies for *OOH → O2 drop to 0.178 eV (Ni) and 0.003 eV (Fe) vs 0.470 eV and 1.154 eV in pristine. O–H bonds in *OH and *OOH are elongated in SU-NiFe-LDH(TA), indicating activation by nearby uncoordinated carboxylates acting as proton ferries.

The study addresses key barriers in NiFe-LDH OER catalysis—kinetic scaling limitations and poor durability due to metal dissolution—by integrating a bioinspired ligand strategy. Static coordination via C–O–Fe bonds anchors Fe/Ni centers, mitigating dissolution and preserving the lamellar framework under harsh alkaline electrolysis and high current densities. Concurrently, uncoordinated carboxyl groups, dynamically present during operation, function as local proton relays that weaken O–H bonds in intermediates (*OH, *OOH), lowering deprotonation barriers and improving kinetics, as supported by operando spectroscopy and DFT energetics. Morphological control achieved by Fe3+-mediated deposition yields ultrathin, subsize nanosheets that are superhydrophilic and superaerophobic, enhancing electrolyte wetting, accelerating O2 bubble detachment, and reducing cavitation-induced damage, which collectively augment mass transport and catalyst longevity. The combination of these static (structural stabilization and electronic modulation) and dynamic (proton-ferry-assisted CPET) effects explains the superior activity (low overpotential, small Tafel slope, low Rct) and exceptional durability (≥1300 h at 1500 mA cm−2; ≥800 h at 1000 mA cm−2 in 6 M KOH, 60 °C).

This work demonstrates a bioinspired anchoring strategy for NiFe-LDH OER catalysts using trimesic acid ligands to create SU-NiFe-LDH(TA) nanosheets with superhydrophilic and superaerophobic surfaces. Coordinated carboxylates (C–O–Fe) statically stabilize metal active sites against dissolution, while dynamically evolving uncoordinated carboxylates serve as proton ferries that facilitate deprotonation steps and accelerate OER kinetics. The catalyst achieves low overpotentials (e.g., 248 mV at 100 mA cm−2; 219 mV at 10 mA cm−2), a small Tafel slope (31.1 mV dec−1), low charge-transfer resistance, and outstanding stability at industrially relevant current densities (1500 mA cm−2 for 1300 h; 1000 mA cm−2 for >800 h in 6 M KOH at 60 °C). Operando spectroscopies and DFT corroborate the intertwined static and dynamic roles of carboxyl ligands. Future research directions could explore: extending ligand families (polycarboxylates, phosphonates, sulfonates) and coordination motifs to other LDH or mixed-metal oxyhydroxide systems; tailoring ligand spatial arrangement and acidity to optimize proton relays; integrating mass-transport-optimized architectures and gas management strategies; and validating long-term performance in large-area industrial electrolyzers and under varying electrolyte compositions.

Related Publications

Explore these studies to deepen your understanding of the subject.