Chemistry

A synthetic cell-free 36-enzyme reaction system for vitamin B<sub>12</sub> production

Q. Kang, H. Fang, et al.

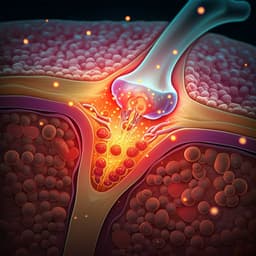

Vitamin B12 (cobalamin) is essential in cellular metabolism and exists in several forms, with adenosylcobalamin (AdoCbl) and methylcobalamin being the natural bioactive coenzymes. Industrial production relies on lengthy microbial fermentations, and while engineered strains can produce intermediates or low titers of B12, the long, highly regulated, multi-step pathway complicates further improvements. Cell-free systems offer advantages such as flexible control, easier separation, tolerance to toxic intermediates, and potentially higher productivity. Prior cell-free works have reconstituted other complex pathways, but de novo cobalamin synthesis had not been achieved due to pathway length, detection challenges, feedback inhibition, and unstable intermediates. This study addresses whether a modular, cell-free, multi-enzyme system with tailored cofactor regeneration can accomplish complete AdoCbl synthesis from 5-ALA and improve titers by resolving key biochemical bottlenecks.

The paper reviews cell-free synthetic systems that successfully reconstituted fatty acid, monoterpene, cannabinoid, and starch biosynthesis, demonstrating feasibility for complex pathways. For cobalamin, previous in vitro efforts produced intermediates such as HBA from 5-ALA using 17 enzymes, nucleotide loop assembly to AdoCbl from adenosylcobinamide using extracts and purified enzymes, and precorrin-2 synthesis via a four-enzyme system. Engineered E. coli platforms expressing >30 enzymes produced vitamin B12 at 0.67 mg/L in 24 h, and other strains produced intermediates (HBAD, Hby ~2.9 mg/L). However, complete de novo cell-free cobalamin synthesis had not been realized due to multiple methylations, ring contraction, metal insertion/reduction, and ligand assembly steps, as well as cofactor balance and inhibitor buildup.

Overall design: The aerobic (late cobalt insertion) AdoCbl pathway was partitioned into five synthetic modules (precursor, HBA, AdoCby, AdoCbl, and two branch modules supplying lower-ligand precursors) and five cofactor regeneration modules. In total, 32 steps catalyzed by 36 enzymes (including 10 enzymes for regeneration) from ten microorganisms were assembled and optimized via design-test-optimize cycles. Thermodynamic analysis (ΔG° computed at pH 8.0, I=0.1 M) indicated the full pathway is favorable (net −486.80 kcal/mol; −685.84 kcal/mol with regeneration).

- Precursor module: HemB, HemC, HemD, and CobA convert eight 5-ALA to precorrin-2. A key bottleneck was the oxidation of uroporphyrinogen III (Urogen III) to dead-end uroporphyrin III; 2% (v/v) β-mercaptoethanol reduced this oxidation by ~80.7% and increased downstream sirohydrochlorin 285.5%. SAH feedback inhibited CobA; replacing exogenous SAM with in situ SAM synthesis from L-methionine (MetK) plus SAH removal by MtnN relieved inhibition and improved precorrin-2.

- HBA module: Eight Cob enzymes (CobI, CobG, CobJ, CobM, CobF, CobK, CobL, CobH) convert precorrin-2 to hydrogenobyrinic acid (HBA). Crude extracts from engineered E. coli expressing the cob operon (with partial/complete cysG knockouts) were combined with purified precursor enzymes. Blocking siroheme branch (ΔcysG variants) improved HBA titers. Buffer and pH optimization favored Hepes-NaOH at higher pH. Fed-batch addition of 5-ALA and SAM (or L-Met with SAM module) and increased extract loading raised HBA titers (up to ~10.95 mg/L).

- AdoCby module: From HBA, reactions include amidation (CobB) to HBAD, Co2+ chelation (CobN/S/T complex) to CBAD, Co reduction (CobR, with FMN/FMNH2 and NADH), and adenosyl transfer (CobA) to AdoCBAD; then CbiP adds (R)-1-amino-2-propanol-O-2-P to form AdoCby. The team screened multiple CobB homologs and optimized conditions (ATP, Co2+, Mg2+, glutamine). They developed stop-flow assays monitoring FMN regeneration, ATP consumption, triphosphate and phosphate formation, and directly detected AdoCBAD and AdoCby by UPLC-MS. Kinetics of CobR (FMN reduction) were measured (Km 0.17 ± 0.03 mM; Vmax 64.91 ± 4.20 mM min−1 mg−1; kcat 60.10 ± 3.89 s−1). A CobR–CobA interaction facilitated energetically challenging Co2+ reduction.

- AdoCbl module and branch modules: Nucleotide loop assembly uses transmembrane enzymes CbiB (adenosylcobinamide-phosphate synthase) and CobS (AdoCbl-5' phosphate synthase) along with other lower-ligand enzymes (e.g., CobT). To enhance membrane enzyme expression and stability, CbiB and CobS were produced as water-soluble SIMPLEx fusion complexes; activity was validated in vivo. Branch module-1 synthesizes (R)-1-amino-2-propanol-O-2-P; branch module-2 synthesizes α-ribazole-5-P from 5,6-dimethylbenzimidazole.

- Cofactor regeneration modules: Custom modules replenished key cofactors and minimized inhibitors/by-products: (1) NADH and 5-ALA regeneration using RocG (glutamate dehydrogenase), OGDH complex, and HemA; (2) glutamine regeneration from glutamate and NH4+ via GlnA (ATP-dependent); (3) ATP regeneration from ADP using polyphosphate kinase PpK and polyphosphate; (4) hydrolysis of tri- and pyrophosphate using inorganic pyrophosphatase PpA to relieve CobA inhibition; (5) SAM module using MetK (from L-Met) with SAH removal by MtnN. Kinetic parameters for PpA and PpK supported their inclusion (e.g., EcPpA Km for triphosphate 0.79 mM; Vmax 46.11 mM mg−1 min−1; PpK Km for sodium hexametaphosphate 0.63 mM; Vmax 4.46 mM mg−1 min−1).

- Reaction modes and analytics: Both one-pot and batch (multi-pot) modes were tested, with batch mode improving titers. Assays used HPLC/UPLC-PDA-MS, LC-MS, fluorescence for sirohydrochlorin, ATP assay kits, and spectrophotometry for FMN/NADH. A cyanide-free post-reaction conversion (sodium nitrite, acetic acid, and E. coli cells at 100 °C) enabled transformation of AdoCbl to CNCbl for stable detection. Bioassay with S. typhimurium AR2680 confirmed activity. Conditions (buffers, pH, reductants, light exclusion) were tuned to protect oxygen- and light-sensitive intermediates.

- First complete cell-free synthesis of adenosylcobalamin (AdoCbl) from 5-ALA demonstrated using 36 enzymes in 32 steps, partitioned into five synthetic and five regeneration modules.

- Titers: 417.41 µg/L AdoCbl from 5-ALA (productivity 14.39 µg/L/h, batch mode with regeneration module 1); 5.78 mg/L AdoCbl from purified HBA in 14 h (productivity 412.77 µg/L/h), reaching 9.15% of theoretical conversion yield.

- HBA production: Achieved up to 10.23–10.95 mg/L HBA by combining β-mercaptoethanol (2% v/v) to suppress Urogen III oxidation (~80.7% prevention) and SAM module (MetK + MtnN) to alleviate SAH inhibition; sirohydrochlorin increased 285.5% upon preventing oxidation.

- Thermodynamics: Net ΔG° for the full pathway is −486.80 kcal/mol; coupling cofactor regeneration reduces it to −685.84 kcal/mol.

- Enzyme-level optimizations: CobR kinetic parameters (FMN Km 0.17 mM; Vmax 64.91 mM min−1 mg−1; kcat ~60 s−1); stop-flow assays confirmed CBAD reduction and CobA/CbiP activities via changes in FMN, ATP, triphosphate, and phosphate. ATP regeneration (PpK) and polyphosphate hydrolysis (PpA) significantly improved AdoCby/Cbl synthesis; increasing PpK raised AdoCbl titer by 75% in one-pot tests.

- Expression strategy: SIMPLEx fusions enhanced soluble expression and activity of integral membrane enzymes CbiB and CobS for nucleotide loop assembly.

- Analytical advances: Developed direct LC-MS detection of AdoCBAD and AdoCby; established a cyanide-free method to convert AdoCbl to CNCbl for robust detection.

The study addresses the longstanding challenge of reconstituting the entire vitamin B12 biosynthetic pathway outside living cells. By modularizing the pathway, diagnosing bottlenecks (e.g., Urogen III oxidation, SAH feedback on methyltransferases, triphosphate inhibition of CobA, energetically difficult Co2+ reduction), and implementing tailored cofactor regeneration, the authors demonstrate de novo AdoCbl production from a simple substrate (5-ALA). Batch-mode operation and regeneration of ATP, NADH, SAM, and glutamine were essential to overcome cofactor competition and feedback inhibition, while SIMPLEx-enabled expression of membrane enzymes facilitated the late-stage nucleotide loop assembly. The achieved titers and productivities are comparable in productivity terms to microbial fermentation benchmarks on a per-hour basis, highlighting the potential of cell-free platforms for complex natural products where genetic engineering and cellular regulation limit yields. The approach provides a blueprint for assembling long, cofactor-intensive pathways in vitro and developing detection methods for unstable intermediates.

This work establishes a synthetic cell-free 36-enzyme system that produces adenosylcobalamin either from 5-ALA (417.41 µg/L) or from HBA (5.78 mg/L), enabled by pathway modularization, mitigation of inhibitory/byproduct effects, and comprehensive cofactor regeneration. Key contributions include relief of SAH inhibition via an in situ SAM module, protection against oxidation of labile intermediates, thermodynamically informed module design, expression of membrane enzymes using SIMPLEx, and novel analytical strategies for intermediate and product detection. Future research should focus on increasing titers and yields (e.g., further enzyme engineering, immobilization, scaffolded channeling), lowering costs (co-purification, enzyme stabilization, cofactor recycling efficiency), improved pH and redox control over long reactions, and translation to other complex biosynthetic pathways for industrial cell-free biomanufacturing.

- Titers from 5-ALA remain modest relative to industrial fermentation; overall yield requires improvement for economic viability.

- High costs of enzyme production/purification and cofactor consumption currently limit input-output efficiency compared with fermentation.

- Instability and oxygen/light sensitivity of multiple intermediates necessitate reductants and anaerobic/dark handling, adding operational complexity.

- Feedback inhibition (e.g., SAH, triphosphate) and cofactor competition require careful balancing; pH drift and accumulated by-products over extended reactions can impair enzyme activity.

- Detection and availability of certain intermediates are challenging, complicating rapid troubleshooting and optimization.

Related Publications

Explore these studies to deepen your understanding of the subject.