Engineering and Technology

A smart ball sensor fabricated by laser kirigami of graphene for personalized long-term grip strength monitoring

H. Zhang, X. Ding, et al.

The study addresses the need for personalized, long-term, simple, and sensitive grip strength monitoring across populations with varying hand sizes and strength levels (e.g., infants, rehabilitation patients). Existing hospital instruments and hand dynamometers are typically designed for adults, are bulky, and lack sensitivity for small grip forces. The authors propose a compact, soft, wireless smart ball sensor that combines a 3D soft elastic ball base and a 3D spiral graphene-based piezoresistive sensing unit fabricated via laser kirigami. They also consider the effect of 3D contact area between the hand and the ball on the sensor readout, using finite-element analysis (FEA) to refine the force estimation model. The purpose is to enable accurate, portable, and personalized grip strength monitoring suitable for babies, children, and patients with weak grip.

Prior work includes large hospital grip instruments and commercial dynamometers that primarily serve adults and rely on rigid handles and pressure sensors, limiting sensitivity to small grip forces and multi-directional loading. Earlier smart ball concepts have been explored for measuring hand grip strength and in serious games for elderlies, but limitations remain in miniaturization, sensitivity, portability, and comprehensive 3D modeling (e.g., Jaber et al., 2012; Lunardini et al., 2020). The paper builds on advances in laser reduction of graphene for high-performance sensing and kirigami techniques for conformal 3D structures, which offer rapid, precise patterning and scalability. Foundational work on kirigami structures, graphene properties, and wearable sensors underpins the approach. The authors highlight the lack of designs tailored to children under 7 years old and rehabilitation patients with weak grip, motivating their soft, miniaturized, and wireless solution with 3D contact-area-aware modeling.

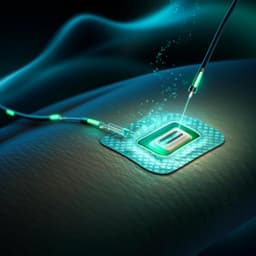

Device design and fabrication: The smart ball sensor comprises (i) a soft elastic PDMS ball base, (ii) two graphene-based spiral piezoresistive sensors patterned on polyimide (PI) via direct laser writing (laser kirigami), (iii) a central transparent pill shell embedding electronics (power, Bluetooth, control), and (iv) an outer sealing/thermochromic layer. The spiral sensing unit is laser reduced and cut on PI (DuPont, 0.075 mm) using a 50 W CO2 laser. Optimized parameters for reduction: speed 1%, power 0.3%, PPI 400 (vector); for cutting: speed 1%, power 0.6%, PPI 400 (raster). A thin PDMS coating encapsulates the graphene to prevent loss. The spiral sensor (diameter ~45 mm; 4 turns; width 2 mm; thickness 0.075 mm) is stretched from 2D to a 3D form and landed onto terraced fields formed on the ball surface; landing position and uniformity are controlled by design matching, fixed landing marks, pre-compression tests, and inspection for uniform landing.

Ball fabrication: Electronics are assembled into a transparent pill shell, suspended centrally within an eggshell mold. PDMS precursor (1:10) is cast and cured at 60 °C to form the ball base; the eggshell is removed. Terraced fields matching the spiral geometry are formed on the ball surface, onto which the spiral is integrated. A thermosensitive PDMS layer with temperature-sensitive pigment coats the exterior.

Electronics, signal acquisition, and power: A microcontroller (STM32F103C8T6, 12-bit ADC) performs data acquisition. A voltage divider and filtering reduce noise; a signal amplification and reference circuit conditions the ADC input. Data are transmitted via Bluetooth to a mobile device for display/analysis. Power is provided by a 3.7–4.2 V Li-ion battery (18×7 mm), managed by TP4056 (charging/protection) and regulated to 3.3 V by TLV62568P. Typical operating current is ~12 mA.

Characterization: Morphology by FE-SEM (Zeiss GeminiSEM 500). Electrical I-V via Keysight B2901A. Mechanical tests with ElectroForce 3200; resistance changes measured by Keysight 34465A or an oscilloscope. Indentation tests used cylindrical indenters (e.g., 25 mm diameter, 3 mm height) to derive the relationship between resistance change and applied force.

FEA modeling: Abaqus 6.14 models an axisymmetric egg-shaped ball (upper semi-ellipsoid 30.67×25 mm; lower hemisphere radius 25 mm; E=200 kPa, ν=0.49) and a rigid cylindrical indenter. Vertical compression (e.g., 10 mm) yields displacement fields; strains at the spiral sensor locations are computed (post-processed in MATLAB). Additional 3D loading simulations vary contact area by imposing different indentation heights to map strain vs. 3D contact area at a fixed force (e.g., 18 N). The authors also modeled 90° and angled compressions but focused analysis on vertical compression due to experimental reliability.

Model derivation: From indentation, the empirical relation ΔR/R0 = α F^2 with α = 1.03×10^-2 N^-2 is obtained under a known contact area S_indenter (≈490.87 mm^2). FEA provides ε ∝ F (ε = k F, k = 1.89×10^-3 N^-1) for the same S_indenter, and ε(S) = ε0 exp(b S) with b = -4.8×10^-4 mm^-2 under fixed force. Combining relations yields ΔR/R0(F,S) = C k^2 F^2 exp(2 b (S - S_indenter)); substituting C k^2 = α gives ΔR/R0 as a function of F and S. As S is hard to measure in practice, the 3D contact area is estimated from an arc length l measured on the ball: S = 2 π r^2 (1 - cos(l/r)), where r is the radius of the lower ball. Final practical equation expresses F as a function of ΔR/R0 and l for mobile computation.

Validation and tests: Accuracy testing used two indenters (S1 ≈ 490.63 mm^2, S2 ≈ 1219.2 mm^2). Forces during indentation provided F_real; sensor signals were converted to F_mon using models with and without contact-area correction. On-body verification included 32 human subjects (adults: 20–35 years; one stroke patient; children aged 1, 3, 5, 7, 9). Hospital instruments/dynamometers provided reference measurements; the smart ball transmitted data wirelessly to a cellphone. Units were reported in kilogram-force for practical comparison (1 kgf = 9.8 N).

- The graphene-based spiral sensing unit exhibits piezoresistive behavior with high sensitivity. Optimized laser parameters (speed 1%, power 0.3%, PPI 400) yielded low resistance (≈4.59 kΩ cm^-1) versus higher-speed settings (≈8.09 and 10.07 kΩ cm^-1). The sensing unit fabricated at higher laser speed tolerated larger tensile strain (up to ~29%) but produced less graphene and lower sensitivity; the study used lower speed (1%) for better sensing.

- The 3D spiral sensor stretched from 2D achieved a resistance change rate of ~76.19 kΩ cm^-1, with resistance up to ~2 MΩ at a maximum stretching height of 21 cm. The ball’s mechanical strength was ~32.97 kPa. Cyclic and stability tests showed repeatable performance under repeated compression.

- Indentation-derived relationship: ΔR/R0 = α F^2 with α = 1.03×10^-2 N^-2 (F in newtons) under a defined contact area (S_indenter ≈ 490.87 mm^2). FEA established ε = k F (k = 1.89×10^-3 N^-1) for that area and ε(S) = ε0 exp(b S) with b = -4.8×10^-4 mm^-2 at fixed force, leading to a contact-area-aware model: ΔR/R0(F,S) = α F^2 exp(2 b (S - S_indenter)). Using S from the measured arc length l via S = 2 π r^2 (1 - cos(l/r)), the practical equation enables mobile readout of F from ΔR/R0 and l.

- Accuracy improved when accounting for 3D contact area. Using an indenter with S2 ≈ 1219.2 mm^2, the accuracies with contact-area correction were 83.12%, 98.76%, and 93.66% at F_real = 6, 12, and 18 N, respectively (average ≈91.85%), versus 69.79%, 82.92%, and 89.29% without correction (average ≈80.67%). The improvement was ~11.18%.

- On-body adult validation against a hospital device showed high agreement: correlation coefficient r = 0.92; Bland–Altman analysis indicated no significant bias. The smart ball provided continuous, wireless readout.

- The device is compact and lightweight (≈44.96 g) compared to a household dynamometer (≈345.62 g), enabling use by children. It measured strong grips in children ≥7 years and detected small grip strength in infants <3 years, where commercial instruments often fail or yield inaccurate values.

- Practical guidance: vertical compression along the device’s axis yields consistent, reliable signals; off-axis (e.g., 45° or 90°) loading produced unstable sensor responses due to non-uniform deformations.

- Additional feature: a thermochromic outer layer provides color change with temperature for engagement/training.

The smart ball sensor’s 3D spiral graphene sensing unit, conformally integrated on a soft ball, captures deformations during grasping with high sensitivity. Incorporating the 3D contact area into the force model via FEA resolves a key source of variability: identical forces with different contact areas produce different strains and resistance changes. By estimating contact area from a simple arc length measurement, the system can compute grip force more accurately in practical settings, which led to an observed ~11% accuracy improvement in validation tests. The strong agreement with hospital instruments (r = 0.92) supports clinical relevance while offering advantages in portability, comfort, and continuous wireless monitoring. These features address unmet needs in pediatrics and rehabilitation where hands are small and grip forces are weak, and where frequent clinical measurements are impractical. While vertical compression yields robust data, off-axis loading remains challenging due to non-uniform deformation of the spiral and the egg-shaped geometry; the design and usage guidelines (egg shape for grip orientation, recommend vertical compression) mitigate this in practical use. Overall, the device presents a pathway for personalized, long-term grip strength tracking outside clinical environments, potentially enhancing disease monitoring, rehabilitation guidance, and health management.

The study presents a fully integrated, portable, and inexpensive smart ball sensor using laser-kirigami graphene spiral sensors on a soft PDMS ball with embedded electronics for wireless grip strength monitoring. A contact-area-aware sensing model derived from FEA and indentation experiments significantly improves accuracy over traditional approaches that ignore 3D contact area. Validation shows high correlation with hospital instruments and sensitivity suitable for children and patients with weak grip. The device’s small form factor, comfort, and continuous readout make it suitable for personalized long-term monitoring. Future work could extend modeling and hardware to robustly handle multi-axis loading, refine real-time estimation of 3D contact area, optimize sensor durability across long-term use, and conduct larger-scale clinical validations across diverse populations.

- Reliable measurements were obtained primarily under vertical compression; off-axis compressions (e.g., 45° or 90°) produced non-uniform spiral deformation and unstable signals, complicating strain calculation and reducing reliability.

- The egg-shaped geometry and non-uniform landing positions of the spiral increase complexity in defining boundary conditions and interpreting strains for non-vertical loads.

- The true 3D contact area is difficult to measure directly; the proposed arc-length method provides an estimate but introduces dependency on correct measurement of arc length and assumed ball geometry.

- Parameter values (e.g., S_indenter) are dependent on the specific indenter and device geometry; recalibration may be required for different sensor sizes or designs.

- Long-term durability and performance under repeated daily use, environmental variability, and diverse user behaviors require further longitudinal study.

Related Publications

Explore these studies to deepen your understanding of the subject.