Chemistry

A robotic platform for the synthesis of colloidal nanocrystals

H. Zhao, W. Chen, et al.

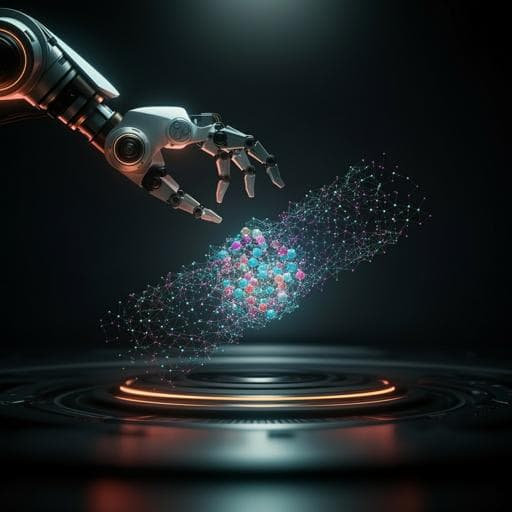

This innovative research introduces a robotic platform that revolutionizes the synthesis of colloidal nanocrystals. By integrating data mining, automated synthesis, and machine learning, the team demonstrates how to control nanocrystal morphologies effectively. This breakthrough opens exciting new pathways for data-driven synthesis in materials science, conducted by the talented authors from the Shenzhen Institute of Advanced Technology and other prestigious institutions.

~3 min • Beginner • English

Introduction

Colloidal nanocrystals (NCs) exhibit important optical, photochemical, electrochemical, optoelectronic and biomedical functionalities, but achieving desired properties hinges on precise morphological control. Traditional trial-and-error synthesis and labor-intensive characterization slow progress. Robotic synthesis and self-driving laboratories, coupled with artificial intelligence (AI), have advanced organic synthesis and some inorganic systems, yet gaps remain for inorganic NCs: limited robot-assisted high-throughput characterization, lack of data-driven translation of synthetic goals to robotic actions, scarce experimentally characterized morphology data for controllable synthesis, and insufficient ML-based correlation identification for inverse design. This study aims to address these gaps by developing a robotic platform that integrates literature-driven hypothesis generation, automated high-throughput synthesis and in situ characterization, ML-based correlation discovery, and morphology-oriented inverse design. Gold NCs (strong visible absorption) and lead-free double-perovskite NCs (photoluminescent) are used as representative systems to demonstrate broad morphological tunability and inverse design of targeted morphologies.

Literature Review

Prior work has established automated platforms for organic synthesis (small molecules, cages/catenanes, peptides, pharmaceuticals) with robotic execution, automated characterization, database construction, and AI-enabled planning or retrosynthesis. Data-driven models have extracted synthesis parameters from patents and translated literature to executable code. In inorganic materials, robotics and AI have been applied to thin films, self-driving discovery, and perovskite screening, but literature-driven parameter mining to guide robotic synthesis of inorganic NCs has been rare. Reported limitations include relatively underexplored robot-assisted high-throughput characterization for inorganic systems and a lack of models linking synthesis parameters to nanoscale morphology enabling inverse design. This work builds upon these advances to extend automation and AI specifically to colloidal NCs, focusing on morphology control.

Methodology

Framework: The platform comprises three stages: (1) data mining of literature to select key synthesis parameters; (2) controllable synthesis with robotic execution and in situ characterization; (3) ML-driven inverse design of targeted morphologies.

Data mining: An automated literature recommendation system downloads literature by keywords, locates target paragraphs via rules, tokenizes with ChemicalTagger, performs chemical named entity recognition (OSCAR), domain dictionary augmentation, unit extraction by regular expressions, POS tagging (OpenNLP), phrase parsing, and statistical analysis of extracted synthesis parameters. For gold NCs, frequency distributions of concentrations for CTAB, AgNO3, HCl, AA, HAuCl4, NaBH4, and seed were compiled from 1,300 papers. The most frequent concentration (L2) was aligned by linear transformation; low (L1) and high (L3) levels were set using Gaussian-expanded fits defining bounds of shaded regions. For lead-free double perovskites, candidate solvents (48) and surfactants (61) were mined from related perovskite literature to seed screening.

Robotic platform: Hardware integrates automated pipettes, sample/consumables storage, synthesis platform, light sources (white/UV), a color-ultrasensitive mobile camera, and a microplate reader/spectrometer, coordinated by a mobile robot and robotic arm. Procedures are encoded via Robotic Execution Excel files (no programming required) and validated/monitored by a simulated operation system. In situ characterization acquires UV–vis–NIR absorption spectra and photographs under white/UV illumination with RGB extraction.

Automated synthesis – gold NCs: Standard stock solutions (CTAB 0.2 M; HAuCl4 0.02 M; AgNO3 0.01 M; HCl 3 M; AA 0.2 M) were prepared. Typical robotic run: CTAB (0.1 M, 1 ml), HAuCl4 (0.01 M, 50 µl), AgNO3 (0.01 M, 10 µl), HCl (1 M, 20 µl), AA (0.1 M, 8 µl) sequentially dispensed with 4 min mixing after each addition (except seeds). Seed (2.4 µl) injected, stirred 10 s, then aged at 28 °C for 12 h. Post-growth, aliquots were transferred for spectral and color measurements. Designs included orthogonal arrays followed by single-factor expansions (24 and 96 levels) and multi-factor (double, triple) experiments targeting SDAs (CTAB, AgNO3, HCl).

Automated synthesis – double perovskite NCs: For Cs4AgInBiCl12/Cs2AgInxBi1−xCl6 systems, stock solutions (CsCl, AgCl, InCl3, BiCl3 in 36–38% HCl) and PVP (20 mg ml−1 in 36–38% HCl) were used. A typical run: 1 ml PVP solution, 500 µl AgCl (5 mM), 500 µl CsCl (0.2 M), 90 µl InCl3 (0.1 M), 10 µl BiCl3 (0.1 M) added to a 24-well deep plate; HCl volume adjusted to keep PVP+HCl = 1,000 µl; mixed 30 s; 250 µl transferred to a transparent plate followed by 1,250 µl isopropanol, instantly forming NCs/microcrystals. In situ UV–vis–NIR spectra and fluorescence images under 365 nm UV were acquired. Solvent screening (48 solvents) and surfactant screening (61 surfactants; 366 experiments) were performed; supernatant photoluminescence and RGB were quantified.

Characterization and validation: In situ proxies included LSPR peak position for gold and normalized absorption at 400 nm (size indicator via Mie scattering) for perovskites; RGB values were extracted from images. Ex situ validation employed TEM for gold aspect ratio (AR) and SEM for perovskite size (down to 64 nm); XRD verified phase formation for Cs2AgInxBi1−xCl6.

Machine learning: The SISSO algorithm (compressed-sensing supervised ML) identified low-dimensional descriptors linking SDAs to morphological proxies and morphology. Operator set included algebraic and transcendental functions. Models were trained for single-, double-, and triple-factor experiments using in situ datasets, with coefficients provided in supplementary tables. Additional ML models mapped normalized RGB to AR (gold) and size (perovskite) for rapid color-based morphology inference.

Inverse design: Using trained ML models and the accumulated experimental database (>2,300 gold and ~1,000 perovskite samples), the platform predicts SDA settings from a desired morphology (AR or size). Predicted recipes were executed robotically and validated via in situ and ex situ measurements.

Key Findings

- Literature mining of 1,300 gold-nanocrystal papers yielded frequency distributions for key reagent concentrations; L1/L2/L3 levels were defined via Gaussian fits for orthogonal and subsequent designs.

- High-throughput robotic synthesis generated 96-level CTAB series showing systematic color change and LSPR shifts; UV–vis–NIR confirmed strong visible absorption from gold NCs.

- For double perovskites, 48-solvent screening identified top performers (ethanol, ethyl acetate, isopropanol, diethyl ether, acetic acid, 1,4-dioxane) with R (red) channel values >240 under 365 nm illumination. Among 61 surfactants, PVP yielded the best supernatant dispersibility and strongest photoluminescence.

- ML correlation discovery (in situ datasets): For gold NCs, CTAB, AgNO3, and HCl were identified as dominant SDAs affecting LSPR. Double-factor ML models showed synergistic CTAB–AgNO3 effects on LSPR; R2 ~0.95 (Fig. 4a). A linear relationship between LSPR and TEM-measured AR was established (R2 reported in main text figure), enabling AR control via SDA tuning.

- Triple-factor experiments (varying CTAB, AgNO3, HCl) produced complex AR response surfaces, confirming multi-parameter morphology control.

- For double perovskites, double-factor ML models (PVP and BiCl3) linked increased PVP/BiCl3 to reduced normalized absorption at 400 nm, indicating smaller sizes (R2 ~0.94; Fig. 4d). SEM validated size control down to 64 nm; XRD confirmed phase purity across compositions.

- Color-based ML: Normalized RGB-to-AR model for gold (R2 = 0.94) and RGB-to-size model for perovskites (R2 = 0.90) enable rapid morphology inference from images.

- Databases: >2,300 gold NC samples and ~1,000 double-perovskite NC samples were robotically synthesized and characterized, supporting robust ML training and inverse design.

- Inverse design demonstrations: Targeted gold nanorods with AR = 4.06 ± 0.41 and double-perovskite crystals at 78 nm (nanosized) and 749 nm (microsized) were synthesized from ML-predicted SDA settings. Effective tunability ranges: AR ~1.90–6.00 (gold) and perovskite size down to 64 nm.

Discussion

The platform addresses the core challenge of translating desired NC morphology into concrete synthesis parameters by integrating literature-driven initial hypotheses, automated high-throughput experimentation, and ML-based correlation discovery. By identifying structure-directing agents (SDAs) that predominantly control morphology (CTAB/AgNO3/HCl for gold; PVP/BiCl3 for double perovskites), the system establishes quantitative links between reagent settings and morphological descriptors (LSPR ↔ AR for gold; normalized 400 nm absorption ↔ size for perovskites) using in situ proxies and ex situ validation. These correlations enable morphology-oriented inverse design—predicting SDA conditions from target AR or size—thus replacing manual trial-and-error with data-driven robotic execution. The significance lies in demonstrating an end-to-end, scalable workflow—from literature mining to inverse design—generalizable to inorganic NCs with distinct optical behaviors (plasmonic vs photoluminescent), while also introducing color-based ML as a rapid, unbiased morphological indicator. The constructed databases underpin model robustness and continual improvement, positioning the platform to accelerate discovery and optimization of NC syntheses.

Conclusion

This work presents a complete robotic framework for colloidal NC synthesis that unifies data mining, automated high-throughput synthesis/characterization, ML-driven correlation discovery, and inverse design. It demonstrates broad morphological tunability for gold and lead-free double-perovskite NCs, quantitatively links SDAs to morphology, and validates inverse design of targeted AR and particle sizes. Color digitalization coupled with ML further enables rapid morphology inference. The platform reduces dependency on expert intuition and manual labor, paving the way for digital, data-driven synthesis of inorganic NCs. Future directions include expanding the materials scope (additional NC compositions and morphologies), enriching the database with multi-modal characterizations, integrating more advanced planning and active learning, and extending inverse design to multi-objective targets (e.g., morphology, stability, and functional performance).

Limitations

- The study focuses on two representative systems (gold and lead-free double perovskites); generalization to broader inorganic NC families requires further validation.

- In situ proxies (LSPR for AR; normalized 400 nm absorption for size; RGB for color) approximate morphology and still require ex situ validation; model accuracy may depend on proxy fidelity and dataset diversity.

- Literature mining accelerates parameter selection but does not fully replace expert curation; biases in published literature and extraction rules may affect initial parameter spaces.

- Triple-factor and higher-dimensional interactions are explored but remain sparsely sampled relative to full parameter space; further data may improve model robustness and inverse design precision.

- Robotic characterization emphasizes optical readouts; incorporation of additional high-throughput structural probes could strengthen morphology-property mapping.

Related Publications

Explore these studies to deepen your understanding of the subject.