Chemistry

A renewably sourced, circular photopolymer resin for additive manufacturing

T. O. Machado, C. J. Stubbs, et al.

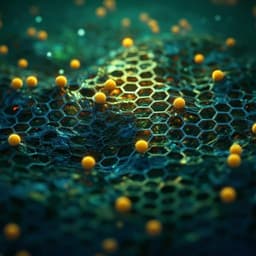

Discover the exciting advancements in sustainable materials with a groundbreaking photopolymer resin derived from renewable lipoates. Developed by Thiago O. Machado, Connor J. Stubbs, Viviane Chiaradia, Maher A. Alraddadi, Arianna Brandolese, Joshua C. Worch, and Andrew P. Dove, this innovative resin allows for high-resolution 3D printing and a circular recycling process, overcoming the limitations of traditional petroleum-based materials.

Playback language: English

Related Publications

Explore these studies to deepen your understanding of the subject.