Environmental Studies and Forestry

Wood-inspired metamaterial catalyst for robust and high-throughput water purification

L. Zhang, H. Liu, et al.

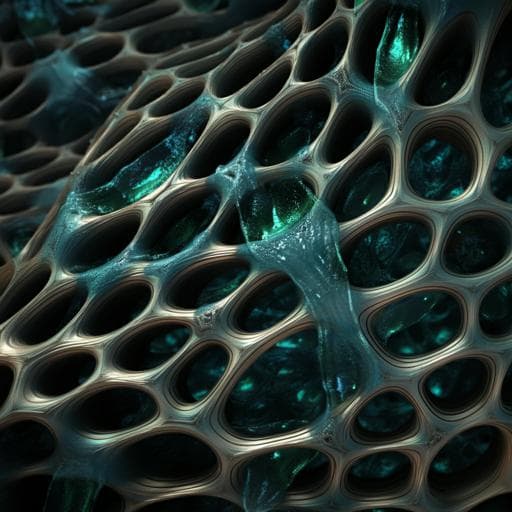

Water quality has deteriorated due to dyes, heavy metals, antibiotics and other pollutants, and current purification systems are multi-step and time-consuming, separating mechanical filtration from chemical catalysis. A key challenge is the strong coupling among structural strength, fluid transport, and catalytic efficiency that prevents simultaneous optimization. Metamaterials with microlattice architectures offer tunable mechanical and transport properties but traditional periodic lattices suffer from coupled geometrical constraints that limit design space: higher strength typically reduces pore volume and permeability. Inspired by Douglas fir wood, whose bimodal and staggered pore distribution decouples transport and strength, the authors propose overlapping body-centered-cubic (BCC) microlattices to create aperiodic, bimodal pores that increase design degrees of freedom, enabling independent tuning of mechanics and transport. To realize a practical system with robust structure and catalytic activity, 316L stainless-steel microlattices are fabricated via selective laser melting (SLM) and then electrochemically decorated with cobalt to form a Co/SS metamaterial catalyst capable of activating peroxymonosulfate (PMS) for pollutant degradation. This structure-function integrated "metamaterial catalyst" targets system-level synergy: mechanical robustness, controlled flow for extended contact time, and high-efficiency catalysis for high-throughput water purification.

Microlattice metamaterials, inspired by atomic lattices, use interconnected struts and periodic pores to tailor stiffness and permeability, and have been applied in load-bearing scaffolds with nutrient transport, heat insulation, and multifunctional devices. Bionic designs further enhance properties: bamboo-like hollow struts improve specific stiffness/strength; lotus-root-like porosity aids bone regeneration by balancing strength and transport. Prior works show controllability of mechanical and transport properties but also reveal intrinsic coupling in regular periodic lattices that limits independent tuning. Additive manufacturing routes vary in cost, precision, and throughput: wire-arc (WAAM) is economical but less accurate; selective laser melting (SLM) balances performance and cost for metals like stainless steel; two-photon lithography with electroplating achieves micro/nano lattices but is specialized and time-intensive. In water treatment, numerous catalytic systems (e.g., MOFs, single-atom catalysts, dealloyed structures, metallic glass composites) have advanced PMS activation and AOPs but often lack scalable structural robustness or integrated flow architectures. This work builds upon these threads by combining a wood-inspired overlapping microlattice with metal 3D printing and post-deposition of Co to decouple mechanics and transport while enabling efficient catalysis.

- Design and fabrication: Overlapping BCC microlattices with bimodal pore distributions were designed by superposing unit cells to introduce staggered large and small pores. Strut diameters of 0.30, 0.35, and 0.40 mm and overlap rates of 0%, 30%, 50%, and 70% were used. Unit cell size was 3 mm; lattices comprised 5×5×5 cells. 316L SS microlattices were fabricated via SLM (HK125): laser power 320 W; scan speed 650 mm/s; layer thickness 50 µm; hatch distance 140 µm; scan vectors rotated 67° between layers. Three samples per topology were printed. Gas-atomized 316L powder: D10=22.3 µm, D50=32.8 µm, D90=47.0 µm.

- Co deposition: Printed lattices were etched in 1 M HCl for 15 min, rinsed, then electrochemically coated with Co in electrolyte containing 0.3 M Co(NO3)2·6H2O and 0.5 M H3BO3 using a three-electrode setup (Ag/AgCl reference, graphite counter). A potential of −1.4 V vs Ag/AgCl was applied for 300 s to deposit Co onto the 316L lattice, followed by DI water and ethanol rinses.

- Characterization: Morphologies via SEM; additive geometric deviations via micro-CT (GE Phoenix) and VG Studio Max analysis. Surface deviations quantified; typical peak deviation <30 µm. Co distribution on surfaces confirmed by SEM.

- Mechanical testing: Uniaxial quasi-static compression at 1.2 mm/min (AG-IC100KN, Shimadzu) per ISO 13314:2011 to obtain Young’s modulus, yield and compressive strengths. Finite element simulations evaluated stress distributions and buckling behavior; material properties for SLM 316L SS used; loading with top platen moving along z, bottom fixed.

- Transport simulation: CFD (COMSOL Multiphysics 5.3a) laminar flow using incompressible Navier–Stokes with water (ρ=1000 kg/m³, μ=1.01×10⁻³ Pa·s). Inlet velocity 1 mm/s unless otherwise stated; outlet pressure 0 Pa. Apparent permeability computed as κ=μ u H/ΔP; velocity and shear rate fields analyzed along lines through pores. Various topologies (SC, FCC, diamond, cuboctahedron, octahedron, octet-truss, BCC) and overlap rates compared.

- Experimental permeability: Falling-head tests using Darcy’s law with measured initial/final head heights (H1, H2) over time (T1−T0). Hydraulic gradient λ=(H1−H2)/H; conductivity K=aH/[A(T1−T0)] ln(H1/H2); permeability Kexp=K μ/(ρ g). CFD vs experiment correlations assessed.

- Water purification tests: Fixed-bed reactor packed with Co/SS metamaterial catalysts. Standard test: 100 mL beaker containing 20 mg/L SMX and 0.2 g/L PMS; solution pumped at 12 mL/min through the fixed bed, then recirculated for kinetic analysis. HPLC used to quantify SMX; pseudo-first-order kinetics: −ln(C/C0)=k t; kinetic constants normalized by occupied volume. TOC measured with Na2S2O3 quench to assess mineralization. HPLC-MS identified intermediates; toxicity estimated via T.E.S.T.

- Reactive species identification: Radical scavenging with 0.5 M MeOH, 0.5 M TBA, and 0.03 M FFA; contributions quantified by kinetic fits. EPR with DMPO and TEMP captured •OH/SO4•− and ¹O2 signals, respectively.

- Electrochemistry: Chronoamperometry (i–t) at OCP with 0.5 M Na2SO4 electrolyte to probe electron transfer: injections of PMS (0.2 g/L) and PMS+SMX (20 mg/L) after 30 s. Polarization scans −0.8 to +1.6 V vs Ag/AgCl at 5 mV/s after 30 min OCP.

- XPS: Co 2p and Fe 2p spectra pre- and post-reaction to track valence changes.

- Long-term stability: Continuous flow with two peristaltic pumps mixing 20 ppm SMX and 0.4 g/L PMS at 0.5 mL/min each into a fixed-bed; effluent collected without recirculation; performance monitored over >100 h; regeneration by Ar/H2 (300 °C, 3 h) assessed.

- Practicality tests: Impact of anions (200 ppm Na2SO4, NaNO3, NaCl, NaHCO3) and humic acid (20 ppm) on SMX degradation; pH effects (3, 5, 7, 9); tests in tap water and Yangtze River water; other pollutants NOR and BPA evaluated.

- Overlapping, wood-inspired bimodal-pore microlattices substantially enhance mechanical robustness and catalytic performance while tuning transport. A 70% overlap design achieved approximately 3× higher strength and 3× higher surface area per unit volume, and 4× higher normalized reaction kinetics compared to traditional (0% overlap) microlattices.

- Mechanical performance: For 0.40 mm struts, Young’s modulus increased from 110.17 MPa (0% overlap) to 367.36 MPa (70% overlap). Finite element analysis showed stress concentration near nodes; increased overlap reduced effective strut length, raising buckling load and stiffness. Manufacturing deviations were minor (surface peak deviation <30 µm).

- Transport behavior: CFD revealed that overlap-induced sub-pores reduced pore velocities and increased shear at liquid–solid interfaces, prolonging contact time. Apparent permeability decreased with overlap rate and increased with larger pores/strut diameters; overlap and strut size jointly expanded tunability. Experimental vs. simulated permeability showed strong correlation across topologies (R²: SC 0.80, FCC 0.97, diamond 1.00, cuboctahedron 0.94, octahedron 0.99, octet-truss 0.90, BCC 1.00).

- Catalytic activity: In fixed-bed PMS activation, both traditional and overlapped lattices fully degraded 20 ppm SMX within 15 min; normalized kinetic constants increased with overlap, with the 70% overlap reaching the highest per-volume rate (reported 0.191 cm³ in normalized metric). Increased strut diameter increased surface area and PMS activation rate.

- Mineralization and intermediates: TOC of unmineralized organics decreased to 24.1% at 15 min and 18.8% at 30 min, indicating substantial mineralization. HPLC-MS detected intermediates; toxicity assessment (T.E.S.T.) suggested most intermediates trend toward reduced toxicity, supporting environmental friendliness of the process.

- Mechanism: Radical quenching quantified contributions: •OH 46.3%, SO4•− 25.5%, non-radical (including ¹O2 and direct electron transfer) 28.6%; EPR detected DMPO–•OH and TEMP–¹O2 signals. Current–time responses indicated electron transfer upon PMS addition and further increase with SMX, evidencing a non-radical electron-transfer pathway. XPS showed cycling between Co(II)/Co(III) and Fe oxidation to Fe(III), consistent with proposed PMS activation cycles and synergistic Co–Fe redox interactions.

- Practical performance: High tolerance to common anions; >93% SMX removal within 15 min in 200 ppm Na2SO4, NaNO3, NaCl; performance decreased in alkaline pH (pH 9) but still 75% removal at 10 min; excellent performance in real waters (tap and Yangtze River): >95% in 15 min. Broader applicability: BPA 95.3% and NOR 98.2% removal within 15 min.

- Stability: Continuous operation >96 h with >90% degradation; after 108 h, deactivation occurred but activity recovered to 98% following Ar/H2 reduction (300 °C, 3 h). Corrosion data indicate some galvanic effects (Fe→Co electron transfer) that reduce SS corrosion resistance yet facilitate Co redox cycling during catalysis.

- Design space: Overlap strategy applicable across multiple microlattice topologies to enhance robustness; not all show monotonic strength gains with overlap due to load-path limits. Overlap increases pressure drop and surface area, enabling tailored trade-offs between permeability and reaction contact time for catalytic systems.

The wood-inspired overlapping microlattice decouples strength from transport by introducing staggered, bimodal pores that simultaneously increase node constraints (enhancing stiffness and buckling resistance) and surface area (enhancing fluid–solid contact). Although permeability decreases with higher overlap due to increased relative density and flow friction, for catalytic fixed-bed operation this lower permeability promotes longer residence time and higher reaction efficiency, as evidenced by higher normalized kinetics at 70% overlap. CFD and experiments consistently show that overlap redistributes velocities and shear toward interfaces, improving mass transfer to catalytic sites. Mechanistically, Co and Fe in the Co/SS framework synergize to activate PMS via mixed radical (•OH, SO4•−) and non-radical (¹O2, direct electron transfer) pathways, supported by scavenger tests, EPR signals, current–time measurements, and XPS-tracked valence cycling. The architecture’s tunable parameters (strut diameter, overlap rate) provide a design paradigm whereby stiffness, permeability, and catalytic contact time can be co-optimized to meet constraints: water flow impact below structural rigidity and flow time equal to or shorter than catalytic time for complete purification. Compared to conventional multi-step purification (separate filtration and catalysis) or purely synthetic high-surface-area catalysts lacking structural robustness, the metamaterial catalyst integrates mechanical integrity, controllable hydrodynamics, and catalytic functionality in a scalable platform suitable for continuous, high-throughput water treatment.

A wood-inspired, structure–function integrated metamaterial catalyst was realized by overlapping BCC microlattices fabricated in 316L stainless steel and post-decorated with Co. The overlap strategy creates bimodal, staggered pores that increase surface area and node constraints, yielding approximately 3× strength and surface area per volume and 4× normalized reaction kinetics relative to traditional microlattices. The resulting Co/SS metamaterial catalysts exhibit robust mechanics, tunable permeability, efficient PMS activation dominated by •OH with significant non-radical contributions, broad water-matrix tolerance, and day-level continuous stability with regenerability. The approach provides a generalizable design and manufacturing framework to tailor strength–transport–catalysis trade-offs through geometric parameters and surface functionalization. Future work could extend this concept to other topologies, materials, and catalytic chemistries, scaling across length scales for applications in flow catalysis, flow batteries, and other structure–function integrated devices.

- Manufacturing and material choices: The study focuses on SLM 316L SS with Co deposition; limited exploration of other printable alloys or coatings with superior catalytic properties or corrosion resistance. SLM introduces minor defects and surface roughness; while largely beneficial for surface area, they can affect transport and cause discrepancies between simulations and experiments.

- Transport–strength trade-offs: Increased overlap reduces permeability; although beneficial for catalysis in fixed beds, it may limit throughput in applications requiring minimal pressure drop. Not all lattice topologies show monotonic strength improvements with overlap due to force-path constraints.

- Corrosion and durability: Co decoration induces galvanic interactions with Fe that diminish SS corrosion resistance in PMS-containing environments; long-term exposure leads to surface passivation/deactivation requiring thermal regeneration.

- Data discrepancies: CFD–experiment permeability mismatches arise from surface roughness, suboptimal head height, and setup gaps; while correlations are strong, absolute values differ.

- Scope of contaminants and conditions: While SMX, NOR, and BPA were tested and real waters examined, broader contaminant classes, complex matrices, and extended pH/ionic strength ranges remain to be evaluated for generalizability.

Related Publications

Explore these studies to deepen your understanding of the subject.