Engineering and Technology

Whispering-gallery-mode full-color laser textiles and their anticounterfeiting applications

J. Ruan, D. Guo, et al.

Discover the groundbreaking innovation of light-emitting fabric, which enables the creation of flexible lasing textiles with vibrant colors! This research, conducted by Jun Ruan, Dan Guo, Ben Niu, Kun Ge, and Tianrui Zhai, introduces a unique method that integrates fabrication and application for advanced wearable display technologies and efficient authentication solutions.

Playback language: English

Introduction

The integration of light into textiles opens up numerous possibilities for wearable technology, personal safety, fashion, and medical therapy. Light-emitting fabrics, with their deformable, porous, and robust characteristics, are crucial for enhancing human-machine interactions. Laser displays, known for their excellent chromaticity, high contrast ratio, and vivid colors, are rapidly advancing in flat-panel displays and flexible devices. Microlaser arrays, with their small size, low thresholds, and on-chip integration capabilities, are actively being researched for their expanding applications. However, the creation of large-area lasing textiles remains largely unexplored.

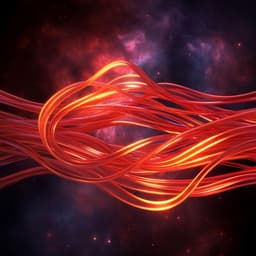

Micro/nanolasers, particularly whispering-gallery-mode (WGM) microcavities, are promising candidates for this application. WGM microcavities, which use total internal reflection to trap light within the cavity, exhibit high quality factors and small mode volumes. Their fabrication methods are compatible with various techniques such as microfabrication, solution-based self-assembly, inkjet printing, and electrospinning, facilitating the integration of functional devices. WGM laser devices have been successfully utilized in full-color laser imaging, biological and chemical sensing, on-chip optical communication, and encryption.

Polymer-based WGM cavities are particularly attractive due to their flexibility and biocompatibility. Polymer microfibers offer both resonant cavities and the necessary flexibility for wearable applications. Therefore, polymers are ideal candidates for manufacturing lasing textiles, however, the mass production of flexible polymer microfibers and their weaving into multicolor lasing textiles needed to be addressed. This research presents a gravity-assisted rotatory drawing method to fabricate mass-produced flexible microfibers, which can be woven into multicolor lasing textiles, and explores their application in anti-counterfeiting measures.

Literature Review

The introduction section thoroughly reviews the existing literature on light-emitting fabrics, laser displays, microlaser arrays, and whispering-gallery-mode (WGM) microcavities. It highlights the advantages of polymer-based WGM resonators for flexible applications and notes the lack of research on large-area lasing textiles. The review emphasizes the diverse applications of WGM lasers and positions the current research within the context of existing work on micro/nanolasers and their integration into functional devices. The authors effectively establish the need for a facile method to fabricate and weave flexible, multicolor lasing microfibers into textiles, setting the stage for their proposed approach.

Methodology

The researchers employed a gravity-assisted rotatory drawing method to fabricate the lasing microfibers. Four laser dyes (S420, Uranin, R6G, and RhB) with emission in blue, green, orange, and red wavebands were used as gain materials. A high-concentration Uranin-doped polymer provided yellow emission via a reabsorption process. The solution for microfiber fabrication comprised polyvinyl alcohol (PVA), sodium dodecyl sulfate (SDS), and the gain materials. The optimized PVA concentration was 176 mg/mL, with SDS crucial for solution viscosity and microfiber formation. SDS reduced surface tension and increased viscosity, leading to uniform microfiber formation with a controlled diameter.

The fabrication process involved a rotatory drum as the microfiber collector, rotated and controlled by a motor. The solution was extruded from a syringe via a peristaltic pump, with the fibers collected on the drum. Gravity assisted fiber formation, unlike electrospinning's reliance on high electrostatic fields, facilitated uniform viscoelastic liquid filament formation between the drum fins. Syringe mobility, controlled by motorized positioning stages, ensured even microfiber arrangement. Solvent evaporation yielded free-standing microfibers, enabling the creation of large-area flexible lasing textiles.

The microfiber diameter was controlled by factors including drum rotation speed, solution extrusion rate, distance between the syringe tip and the drum, and solution viscosity. SDS concentration significantly impacted viscosity, affecting microfiber diameter. Increasing SDS concentration (above the critical micelle concentration) from 10 to 50 mg/mL increased viscosity and microfiber diameters from 4.8 to 65.3 µm.

The mode spacing of microfibers with varying diameters was investigated. The free spectral range (FSR) decreased with increasing diameter, consistent with WGM cavity resonances. Lasing properties of microfibers doped with S420, Uranin, and RhB were assessed by analyzing PL spectra evolution with increasing pumping fluence. Thresholds were determined for each dye, with RhB exhibiting a higher threshold due to a smaller absorption cross-section in the UV waveband. The quality factor (Q) was calculated to be approximately 18,000.

RGB lasing microfibers were woven into a triangular pattern for tunable lasing. Selective pumping position and spot size controlled the color gamut, which covered approximately 79.1% more perceptible colors than standard RGB space. The number of microfibers influenced color temperature.

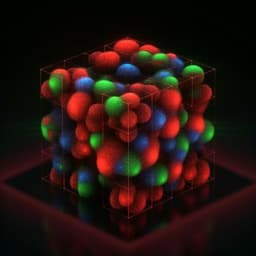

For anti-counterfeiting applications, the PVA microfibers were treated with glutaraldehyde vapor to make them waterproof. TiO2 nanoparticle (NP) patterns were inkjet-printed onto the textiles. TiO2 NPs, with a high refractive index, introduced scattering loss, disrupting lasing action and creating a binary code (lasing/fluorescence) for information encryption.

Key Findings

This research successfully demonstrated a facile and scalable method for producing flexible, multicolor lasing microfibers. Key findings include:

1. **Gravity-Assisted Rotatory Drawing:** A novel gravity-assisted rotatory drawing method was developed to fabricate large-area, flexible lasing microfibers. This method avoids the use of high voltage electric fields, offering a safer and more scalable approach compared to traditional electrospinning techniques.

2. **Color and Mode Tuning:** By varying the concentration of doped dyes and solution viscosity (controlled by SDS concentration), the researchers successfully controlled the emission color and lasing modes of the microfibers, achieving a wide range of colors across the visible spectrum.

3. **Wide Color Gamut:** Weaving the resulting microfibers into textiles produced full-color lasing textiles with a color gamut 79.1% larger than the standard RGB color space. This significant expansion of the color gamut opens up exciting possibilities for vibrant and dynamic displays.

4. **Waterproof and Durable Fibers:** Treatment with glutaraldehyde vapor rendered the PVA microfibers waterproof and durable, maintaining their lasing properties even after prolonged exposure to water and bending. This crucial step enables practical application in various environments.

5. **Anti-counterfeiting Application:** The integration of inkjet-printed TiO2 nanoparticle patterns enabled the creation of an anticounterfeiting technology. The nanoparticles disrupted the lasing action in specific areas, creating a unique binary code that can store information, offering a high level of security and authentication.

6. **Whispering Gallery Mode Confirmation:** The observed lasing behavior was confirmed to be based on whispering gallery mode resonances within the cylindrical microfibers. The analysis of free spectral range (FSR) and quality factor (Q) supported this conclusion, confirming the underlying optical mechanism.

7. **Tunable Lasing:** The lasing properties, including color, were shown to be tunable by varying the pumping conditions (position and intensity), suggesting the potential for creating dynamic and interactive textile displays.

Discussion

This study successfully addresses the challenge of fabricating large-area flexible lasing textiles. The gravity-assisted rotatory drawing method provides a scalable and efficient approach for mass production. The ability to tune the lasing color and modes expands the potential applications beyond simple displays. The incorporation of TiO2 nanoparticles for anticounterfeiting offers a novel and practical application with significant implications for security and authentication. The wide color gamut achieved surpasses standard RGB, indicating superior visual capabilities. The demonstrated stability and durability of the lasing textiles under various conditions indicate their suitability for real-world applications. However, further research is needed to explore the long-term stability of the textiles under extreme conditions and to explore potential improvements to the printing technique for even higher resolution patterns.

Conclusion

This research successfully demonstrated a facile and scalable method for producing flexible, multicolor lasing textiles. The gravity-assisted rotatory drawing method, coupled with dye and viscosity control, enabled the creation of a wide color gamut. Further treatment provided waterproof and durable fibers suitable for practical applications. Finally, the integration of TiO2 nanoparticle patterns demonstrated an effective anticounterfeiting technique. Future research could explore the integration of other functional materials, optimization of printing techniques for higher resolution, and long-term stability studies under varied environmental conditions.

Limitations

While the study successfully demonstrated the fabrication and application of lasing textiles, there are a few limitations to consider. The current method might not be easily scaled to extremely large-scale production, although the process described is more scalable than other techniques. The long-term stability of the lasing performance under various environmental conditions and repeated bending and washing cycles requires further investigation. The resolution of the anti-counterfeiting patterns could be enhanced to improve the security level. Finally, a more detailed cost analysis comparing this method to other fabrication techniques would strengthen the practical implications of this work.

Related Publications

Explore these studies to deepen your understanding of the subject.