Engineering and Technology

Unlocking the potential: analyzing 3D microstructure of small-scale cement samples from space using deep learning

V. Saseendran, N. Yamamoto, et al.

Human space exploration requires extraterrestrial infrastructure, motivating use of in-situ resources (e.g., lunar regolith with cement-like binders). Tricalcium silicate (C3S), a major component of OPC, governs hydration and resulting microstructure. Space-returned hydrated C3S samples are small and highly porous, limiting conventional characterization. The study asks whether high-fidelity 3D microstructures of such samples can be reconstructed from limited 2D SEM images using deep learning, enabling representative volume elements (RVEs) for mechanical and transport property prediction. The purpose is to develop and validate an AI-assisted framework that generates statistically equivalent 3D microstructures from 2D exemplars for both microgravity (µg) and ground (1g) samples, enabling process-structure-property studies with sparse experimental data. The importance lies in providing quantitative 3D information where direct 3D imaging is impractical, supporting materials research for space construction.

Microstructure reconstruction approaches include: (1) statistical modeling methods using low-order probability functions (e.g., two-point correlation, lineal-path, cluster functions) and physical descriptors (e.g., grain/pore size); (2) visual features-based methods; and (3) AI/deep learning methods, particularly CNNs. Material-system-dependent deep models (e.g., deep belief networks) require retraining per material, while transfer learning approaches leverage pre-trained networks (e.g., VGG-19 trained on ImageNet) for material-independent reconstruction. Texture-synthesis-based methods model exemplars as Markov Random Fields and use CNN-based texture features (e.g., Gram matrices of VGG activations) to achieve statistical equivalence more efficiently than optimization-based methods. Solid Texture Synthesis (STS) extends 2D texture synthesis to 3D, producing solid textures from 2D exemplars via slice-based perceptual losses and multi-scale noise generators. Prior works show success on porous media and natural materials, suggesting applicability to cement microstructures. Limitations of visual similarity alone necessitate quantitative statistical validation; hyperparameter tuning and descriptor choice impact results.

Materials and hydration: C3S paste prepared at water-to-cement ratio 2.0 by mass (5 g C3S, 10 g lime-water) to avoid unrealistic rapid initial reaction at high w/c. Mixing performed in plastic bags that separate constituents until mixing, both on ISS and ground. Conditions: 20 ± 2 °C, 1 atm, 35% RH; manual mixing to homogeneity; sealed hydration throughout. Space samples hydrated on ISS for 42 days before return; only variable between space and ground was gravity. Microscopy: Polished samples prepared at day 152 after initial hydration. Backscattered electron (BSE) micrographs of fracture surfaces acquired on FEI Q250 at 500× magnification. Dataset: 20 images (µg) and 30 images (1g), resolution ~1536 × 1024 pixels, 0.54 µm/pixel, archived in NASA PSI database. Image analysis segmented phases: C–S–H, portlandite (CH), and porosity. Micro-CT: Zeiss Xradia 620 Versa used; specimens ~10 × 6 × 6 mm. Thresholds to discern phases derived from BSE-based phase fractions (Table 1). Phase-segmented 3D virtual samples evaluated with low-order probability distribution functions (two-point correlation S2, lineal-path L2, two-point cluster C2). Image preprocessing and segmentation: BSE images underwent histogram enhancement (0.3% saturated pixels) and Sigma filter (σ = 2.0). Greyscale histogram-based segmentation used the overflow method to separate phases with large atomic-number contrast (porosity vs C–S–H) and local minima to separate C–S–H and CH. Area fractions computed; porosity also measured by mercury intrusion porosimetry (MIP) for comparison. Deep learning-based 3D reconstruction: Adopted the solid texture synthesis framework of Gutierrez et al. A compact multi-scale 3D CNN generator G maps multi-channel 3D white noise Z to a volumetric texture v = G(Z0). Architecture uses convolution, upsampling, and concatenation across scales, enabling arbitrary output sizes. Training uses a 3D slice-based perceptual loss comparing 2D slices of generated volumes vd,n along directions d ∈ {1,2,3} to the 2D exemplar ud. A pre-trained descriptor network (VGG-19) extracts feature maps; Gram matrices of feature activations define a texture loss: Loss = ||G^T(F^T(vd,n)) − G^T(F^T(ud))||_F^2. Slice-based comparisons reduce memory demands, allowing high-resolution exemplars. Grayscale images are supported without major changes. Optimization via Adam with initial learning rate 0.1 for 3000 iterations; learning rate decays by ×0.1 at epochs 300, 1000, and 2000. Exemplar regions of interest (ROIs) sized 256×256 and 512×512 pixels were selected (0.54 µm/pixel). Qualitative validation used orthogonal slices; quantitative validation used S2, C2, L2 computed on both reconstructed and micro-CT sub-volumes in X, Y, Z directions. RVE and exemplar selection considerations: For µg samples, CH plates are ~100–115 µm long; thus, at 0.54 µm/pixel, exemplars should be at least ~200×200 pixels to capture geometry. Given resolution, 256×256 pixels suffice for 1g (uniform CH), while 512×512 pixels are recommended for µg (anisotropic plate-like CH). RVE edge length for hydrated cement paste typically 150–200 µm; generated volumes can exceed exemplar size due to fully convolutional generator.

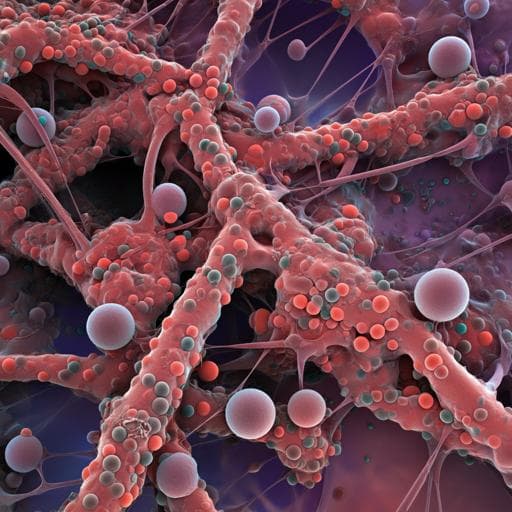

- SEM/BSE image analysis and MIP: µg samples exhibited much higher porosity and distinct CH morphology compared to 1g. • Ground (1g): Porosity 47.0 ± 14.2%; MIP porosity 48.4%; C–S–H 41.6 ± 12.0%; CH 11.3 ± 2.8%. • Microgravity (µg): Porosity 70.3 ± 1.4%; MIP porosity 69.4%; C–S–H 21.2 ± 1.2%; CH 8.5 ± 1.4%. • CH morphology: uniform distribution in 1g vs elongated plate-like crystals in µg.

- Deep learning reconstruction quality: • Reconstructed 3D volumes visually matched 2D exemplars and micro-CT virtual sub-volumes for both 1g and µg, including plate-like CH in µg and uniform CH in 1g. • Training loss converged by ~1500 iterations for 512×512 exemplars.

- Statistical descriptor validation (S2, C2, L2): • Portlandite (CH): Reconstructed 1g volumes captured phase connectivity and isotropy consistent with micro-CT (S2, C2→0 indicating discontinuous clusters; L2 matched micro-CT and went to zero beyond normalized path length ~0.2). For µg, minor perturbations in S2 between ~0.08–0.2 suggested slightly more clustered CH in micro-CT than reconstruction; anisotropy detected (higher C2 in Z), consistent with plate-like CH. • Porosity: L2 approached zero beyond normalized path length ~0.5, indicating no long continuous clusters across full directions; C2 did not converge to zero, indicating percolating porosity networks in both samples. Reconstructed volumes matched micro-CT trends across directions.

- Practical guidelines: • Exemplar size/resolution: At 0.54 µm/pixel, 256×256 pixels recommended for 1g; 512×512 pixels for µg to capture ~100–115 µm CH plates; minimum ~200×200 pixels to capture µg CH features. • RVE size: Edge length ~150–200 µm recommended for mechanical characterization; generated volumes of ~275 µm edge captured key features.

- Utility: Reconstructed volumes are suitable as RVEs for micromechanics and transport modeling, enabling creation of statistical ensembles for probabilistic property estimation using sparse 2D data.

The study demonstrates that a transfer-learning-based solid texture synthesis framework can reconstruct statistically equivalent 3D microstructures from limited 2D SEM exemplars for C3S pastes hydrated in both microgravity and terrestrial conditions. Visual comparisons with micro-CT sub-volumes and quantitative agreement in low-order statistics (S2, C2, L2) show that essential morphology, connectivity, and anisotropy—especially the plate-like CH in µg—are captured. This addresses the challenge of limited sample size and high porosity that preclude standard 3D characterization, enabling RVEs for downstream structure-property simulations. Differences observed (e.g., slight S2 perturbations in µg) highlight sensitivity to exemplar content and slice-based training but remain minor at the low-order descriptor level. The work also clarifies exemplar field-of-view/resolution trade-offs critical to capturing anisotropic features and informs RVE sizing. Overall, the findings validate the approach as a cost-effective alternative or complement to micro-CT, particularly when 3D imaging is infeasible, thereby advancing process–microstructure–property studies for space-cured cementitious materials.

An AI-assisted, material-system-independent framework was developed to reconstruct 3D microstructures of C3S cement pastes hydrated in microgravity and on Earth from high-resolution 2D BSE images. The method generated volumes that visually and statistically matched micro-CT virtual data, captured the distinct plate-like CH morphology in µg and uniform CH in 1g, and produced RVEs suitable for micromechanical and transport analyses. The study provided practical guidance on exemplar size/resolution and RVE dimensions, enabling reliable statistical ensembles for probabilistic property prediction with sparse data. Future work will incorporate higher-order evaluation metrics (e.g., moment invariants), investigate materials-science-specific descriptor networks (e.g., MicroNet) and non-VGG architectures, mitigate generative artifacts (e.g., checkerboard via weighted losses), and extend validation to other heterogeneous material systems.

- Validation used low-order statistical descriptors (S2, C2, L2), which may not fully capture higher-order morphological differences; minor discrepancies observed (e.g., µg S2 perturbations). Higher-order metrics are needed for more stringent validation.

- Descriptor network (VGG-19) is pre-trained on natural images; domain mismatch may limit optimal feature representation for materials microstructures. Influence of alternative descriptors remains unquantified.

- Texture-synthesis artifacts (e.g., checkerboard) can appear, especially with small exemplars; mitigation requires additional loss terms and tuning.

- Exemplar field-of-view/resolution critically impacts reconstruction of anisotropic phases; small or low-resolution exemplars may miss key features and bias reconstructions.

- GPU memory constraints limit exemplar size and training configurations; slice-based training alleviates but does not remove this constraint.

- Micro-CT and segmentation thresholds introduce uncertainties; MIP provides total porosity but limited pore size distribution information.

Related Publications

Explore these studies to deepen your understanding of the subject.