Engineering and Technology

Ultra-sensitive, highly linear, and hysteresis-free strain sensors enabled by gradient stiffness sliding strategy

F. Xue, Q. Peng, et al.

Researchers have made a breakthrough in strain sensor technology with a gradient stiffness sliding design strategy, achieving a remarkable gauge factor of 9.1 × 10⁴ and an impressive linearity of R² = 0.9997. This study, conducted by Fuhua Xue, Qingyu Peng, Renjie Ding, Pengyang Li, Xu Zhao, Haowen Zheng, Liangliang Xu, Zhigong Tang, Xinxing Zhang, and Xiaodong He, opens the pathway for ultra-high sensitivity and linearity in various sensing applications.

~3 min • Beginner • English

Introduction

The study targets the longstanding challenge of simultaneously achieving high sensitivity and high linearity in flexible strain sensors for applications such as electronic skins and health monitoring. Conventional piezoelectric sensors respond rapidly but cannot detect static loads. Resistive sensors can reach very high gauge factors but typically suffer from nonlinear responses and hysteresis, complicating calibration and reducing measurement accuracy when pre-strain is present in practical installations. Capacitive sensors intrinsically offer linearity and low hysteresis due to Poisson-effect-driven geometric changes, but their sensitivity is theoretically limited (GF ~ 1). Consequently, there is a pressing need to overcome the sensitivity limit of capacitive strain sensors while retaining linearity and minimal hysteresis across a broad strain range.

Literature Review

Prior work to enhance strain sensor performance includes active material engineering and structural designs. Auxetic mechanical metamaterials with negative Poisson’s ratio have been used to redistribute strain and amplify sensitivity in resistive sensors. Nacre-inspired designs (high-stiffness Cr cells with stretchable Ag mortar) modulate local strain to prevent crack propagation and enhance sensitivity by orders of magnitude. In capacitive sensors, parallel-plate architectures inherently limit sensitivity; advances include integrating auxetic structures (yielding GF ~1.61), wrinkled electrodes to introduce out-of-plane degrees of freedom (GF > 3), and fragmented electrode-dielectric structures that function as transmission lines with strain-dependent attenuation (GF > 37 at 3% strain). Despite efforts, significant sensitivity improvement alongside high linearity remains challenging.

Methodology

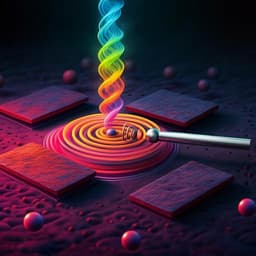

Design principle (GSS): Two gradient-stiffness films are assembled head-to-tail so that, under uniaxial strain, only the soft regions elongate while the stiff regions deform minimally. This causes a strain-dependent increase in the facing/contact area between an upper electrode and an ionic layer, forming electric double layers (EDLs) with very high specific capacitance. The contact area increases linearly with applied strain up to a theoretical limit of 50% strain.

Fringe-field mitigation: Finite-element analysis revealed locally enhanced electric fields at electrode edges causing nonlinear capacitance increase under small strains. To counteract this, the upper electrode was shaped as a trapezoid with angle θ (optimized at θ ≈ 87°) and chamfered to balance the convex fringe-field-induced response with a concave shape-induced response, producing overall linear behavior.

Fabrication of gradient-stiffness layers and assembly: A 0.15 mm flexible PVC film was half covered; the exposed half underwent 30 min plasma treatment to allow bonding. PDMS (monomer:cross-linker = 10:2) was cast onto the treated half and cured at 70°C for 20 min to form a stiff region bonded to PVC. Ecoflex-0030 was cast on the untreated PVC half, fusing with PDMS at the splice and curing at 75°C for 12 h to form a soft region that remained unbonded to PVC, allowing sliding. Both PDMS and Ecoflex parts were 0.5 mm thick. A 0.02 mm titanium sheet (or sputtered Au) was attached on the PVC side corresponding to the Ecoflex as the upper electrode. A 0.5 mm PAM/LiCl ionic layer was cast atop the electrode. Two such gradient-stiffness layers (one with only electrode, the other with electrode plus ionic layer) were assembled head-to-tail; ends were bonded with PDMS. Optional lubricant (talc, 0.1 g) was added between Ecoflex and PVC to facilitate sliding. Device size: 30 × 10 mm.

Ionic layer preparation (PAM/LiCl): Acrylamide (8.34 g), sodium acrylate (1.586 g), and N,N'-methylenebisacrylamide (0.115 g) were dissolved in 100 mL DI water (solution A). Ammonium persulfate (1.11 g) was dissolved in 10 g DI water (solution B). LiCl (2.54 g) was dissolved in 10 mL of solution A in an ice bath. The pre-gel was mixed with 15 µL TEMED and 50 µL of solution B, then cast on the electrode to form the ionic layer.

Finite-element analyses: Mechanical FEA modeled PDMS and PVC as linear elastomers (Young’s modulus: PDMS 1.98 MPa, PVC 3500 MPa; Poisson’s ratios 0.45 and 0.38). Ecoflex was modeled with the Yeoh hyperelastic model (N=3; C10=5072 J·m−3, C2=−331 J·m−3, C3=−15 J·m−3). Electrical FEA applied the Gouy-Chapman-Stern model for EDLs and coupled Nernst-Planck-Poisson equations for ion transport and potential. A 2D model with denser surface meshing was used; electrode voltage sin(2π·1000 Hz·t) V; analysis at t=0.51 ms; ion concentration set to 10−3 mol/m3.

Measurements: Capacitance measured with an LCR meter (Keysight E4980A) at 1 kHz (response time tests at 10 kHz). Mechanical tests used a tensile stage with 100 N load cell. Dynamic tests included strain rates of 0.25, 0.5, and 1 mm s−1; cycling up to 2000 cycles at 40% strain. Microstructures of transparent electrodes were characterized by SEM (Supra55).

Key Findings

- The Gradient Stiffness Sliding (GSS) iontronic capacitive sensor achieves ultra-high sensitivity and linearity simultaneously across the entire strain range.

- Reported gauge factor (GF): 9.1 × 10⁴ (abstract) and 9.1 × 10⁶ (main text), with linearity R² = 0.9997 over the full sensing range.

- Response time: 17 ms at 0.5% strain.

- Limit of detection (LOD): 0.003% strain.

- Minimal hysteresis under loading/unloading cycles; excellent rate insensitivity (ΔC ≈ 7.2 µF at ε = 30% for 0.25, 0.5, 1 mm s−1).

- Stability: Static stability under 10% and 40% strains for 60 min with negligible drift; dynamic stability over 2000 cycles at 40% strain without signal drift.

- Linearity robustness: Stepwise tests at initial strains of 10%, 20%, 30%, 40% showed identical slope (0.4) for ΔC vs. time; identical Δε = 5% produced ΔC = 1.2 µF irrespective of initial strain.

- Large signal span: Capacitance changes from initial pF (very small initial contact area) to µF due to EDL formation, spanning seven orders of magnitude, enabling detection of tiny stimuli (e.g., gentle breathing).

- Measurement precision: From linear calibration, measured strain fluctuations were 0.201366 ± 0.000001 at 20% strain and 0.400766 ± 0.000004 at 40% strain.

- Structural advantages: The active electrode/ionic layers do not bear large strains; the soft Ecoflex can extend >800%, offering over-stretching tolerance. The ionic hydrogel is encapsulated, mitigating water loss and improving stability.

- Theoretical strain range: Linear contact-area increase up to ~50% strain (beyond which contact area decreases).

Discussion

The GSS strategy leverages heterogeneous deformation: only the soft regions elongate under uniaxial strain, increasing the electrode–ionic layer contact area in a controlled, linear manner. This geometrically induced area growth translates directly into EDL capacitance growth, enabling a linear electrical response while amplifying sensitivity far beyond conventional parallel-plate capacitive sensors, which cannot effectively modulate interfacial EDL capacitance. Fringe-field-induced nonlinearity at small strains was analyzed via coupled electrochemical–electrostatic simulations; shaping and chamfering the upper electrode (trapezoid with θ ≈ 87°) balanced fringe-field effects with geometrical factors to restore linearity from zero to high strains. The sensor exhibits negligible hysteresis and fast response, addressing typical shortcomings of resistive sensors, and shows excellent stability over thousands of cycles. Its linear output simplifies calibration and improves measurement accuracy, particularly in scenarios with unavoidable pre-strain. The encapsulated ionic layer also reduces dehydration, improving long-term performance. Collectively, these findings demonstrate that structural design controlling local fields and deformation can simultaneously achieve ultra-high sensitivity and linearity, and the approach is generalizable to other flexible sensing modalities.

Conclusion

This work introduces a gradient stiffness sliding (GSS) structural strategy for capacitive strain sensors that fundamentally breaks the traditional sensitivity limit while preserving full-range linearity and negligible hysteresis. By controlling heterogeneous deformation and localized electric fields, the device achieves ultra-high gauge factors, R² ≈ 0.9997 linearity, fast response, and robust, stable operation over extended cycling. The design also confers over-stretching tolerance and mitigates hydrogel dehydration via encapsulation. The GSS concept provides a generalizable pathway for enhancing performance in other flexible sensor types. Future research could optimize electrode geometries and materials to further minimize fringe-field effects at ultra-low strains, integrate low-drift ionic systems to extend operational lifetimes, and develop compact readout electronics that capitalize on the wide dynamic range while managing instrumentation-induced errors at high capacitance.

Limitations

- Instrumentation limits: Absolute measurement error of LCR meters increases with capacitance, making it difficult to fully realize the theoretically predicted sensitivity, especially at large strains with very high capacitance values.

- Small-strain nonlinearity: Fringe-field effects cause initial nonlinearity at very low strains; although mitigated via electrode shaping and chamfering, residual effects may persist depending on geometry and fabrication tolerances.

- Strain range ceiling: Theoretical linear operation is limited to ~50% strain; beyond this, the electrode–ionic layer contact area can decrease.

- Hydrogel considerations: While encapsulation reduces water loss, hydrogel-based ionic layers can still be sensitive to environmental conditions over very long-term operation.

- Generalizability to diverse use-cases may require tuning of stiffness gradients, electrode shapes, and ionic compositions to balance sensitivity, linearity, and durability.

Related Publications

Explore these studies to deepen your understanding of the subject.