Engineering and Technology

Toward a circular economy: zero-waste manufacturing of carbon fiber-reinforced thermoplastic composites

P. R. Barnett, N. S. Hmeidat, et al.

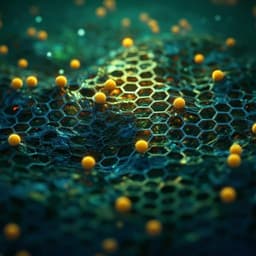

Discover groundbreaking research by Philip R. Barnett, Nadim S. Hmeidat, Bingqian Zheng, and Dayakar Penumadu, as they tackle the limitations of current recycling technologies in fiber-reinforced composites. This innovative work demonstrates how recycled carbon fibers and polyphenylene sulfide can be remanufactured while maintaining fiber length and reducing variability, paving the way for a more sustainable future in composite remanufacturing.

Playback language: English

Related Publications

Explore these studies to deepen your understanding of the subject.