Chemistry

Tough, stable and self-healing luminescent perovskite-polymer matrix applicable to all harsh aquatic environments

Y. Liu, T. Chen, et al.

Discover a groundbreaking luminescent composite that is transparent, tough, and self-healing, even in extreme environments! This innovative material, developed by Yuncong Liu and team, showcases impressive toughness and strain capabilities, making it a game-changer in both dry and wet conditions.

~3 min • Beginner • English

Introduction

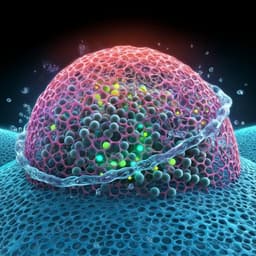

Metal halide perovskite quantum dots (QDs) offer high quantum efficiency, tunable bandgaps, and narrow emission, making them attractive for luminescent devices. However, their low formation energy, ionic character, and surface traps lead to poor stability against moisture, temperature, and chemical environments, limiting practical use. For marine wearable devices, constant deformation and saltwater further challenge stability. Embedding QDs in polymers can protect them, but common matrices like PMMA and PS are not stretchable, and organogels may lack mechanical strength. There is a need for materials combining strong mechanics, high stretchability, environmental stability across harsh aqueous conditions, and self-healing. Building on prior work using ion-dipole interactions to stabilize ionic species and impart self-healing, the authors hypothesize that leveraging strong dipolar CF3 groups in a fluorinated elastomer will afford strong ion-dipole interactions with positively charged perovskite QDs, yielding a transparent, tough, stretchable, and underwater self-healable luminescent composite.

Literature Review

Stabilization strategies for perovskite QDs include surface passivation, ligand engineering, lattice/substitutional approaches, and embedding within polymer matrices. Embedding in polymers can form a protective encapsulation, but widely used matrices (PMMA, PS) lack stretchability. Polyacrylate organogels yield water-stable stretchable gels but with relatively low mechanical strength. For wearable optoelectronics, materials must be mechanically robust, highly stretchable, and stable against diverse harsh environments, and should recover function after damage (self-healing). Prior work by the authors demonstrated that ion-dipole interactions (e.g., between CF3 groups and cations) stabilize ionic conductors in water and enable self-healing, though earlier systems suffered from low modulus due to plasticization. This background motivates a fluorinated, highly dipolar elastomer matrix to enhance compatibility with perovskite QDs while delivering mechanical robustness, environmental stability, and autonomous self-healing.

Methodology

Design and synthesis: An all-dipole fluorinated elastomer was designed by copolymerizing 2,2,2-trifluoroethyl methacrylate (TFEMA, rigid segment) and 2,2,3,4,4,4-hexafluorobutyl acrylate (HFBA, soft segment) to form TFE-HF with high density of terminal CF3 dipoles. CsPbBr3 QDs were synthesized via hot-injection of Cs-oleate into PbBr2 solution in ODE with OA/OAm, followed by purification. For composites, QDs were mixed directly with TFEMA/HFBA monomers and photoinitiator (HMPP), then photo-crosslinked to obtain transparent TFE-HF-QD elastomers. Compositions TFE-HF-QDx (x = TFEMA/HFBA molar ratio) were prepared at fixed QD loading (~1%). A non-fluorinated control copolymer EMA-nBA with QDs was also prepared.

Characterization: Structural characterization included UV–vis transmittance, XRD (phase identification), TEM (QD dispersion and size), confocal fluorescence imaging (3D uniformity), AFM and SEM (surface morphology and roughness), XPS (binding energy shifts to probe ion-dipole interactions), and 19F solid-state NMR (chemical shift changes upon QD incorporation). Mechanical testing involved uniaxial tensile tests (stress–strain, Young’s modulus, fracture energy), cyclic loading, rate dependence, creep, DMA (E′, E″, tan δ), and demonstrations (lifting a 4 kg load). Optical properties were assessed by UV–vis absorption, PL spectra and CIE coordinates, time-resolved PL (TCSPC) to extract multi-exponential lifetimes and average lifetimes, and absolute PLQY in an integrating sphere.

Stability tests: Samples were immersed up to one month in deionized water, HCl (pH 1), NaOH (pH 13), and salty seawater. Mechanical stress–strain behavior and PL intensity/PLQY were monitored over time. Water contact angle was measured to gauge surface hydrophobicity. Resistance to organic solvent (hexane) was compared with SEBS.

Self-healing evaluation: Samples were cut and rejoined without external stimuli in air and in water, saline, acid (pH 1), and base (pH 13). Healing efficiency (η) was quantified as the fraction of recovered toughness relative to the original. Healing progression was examined by optical microscopy and SEM. Dielectric spectroscopy (10−1–10^6 Hz; 10–50 °C) provided segmental relaxation times (VFT fitting) related to chain mobility. AFM-based cohesion force measurements compared intact surface vs freshly fractured interface to assess dipole-dipole contributions. 19F SSNMR compared undamaged, damaged, and healed samples to infer CF3 mobility changes (T2-related). Elevated temperature healing (40 °C) was also assessed.

Applications: Large-area plates and luminescent textiles were fabricated. Cotton fibers were dip-coated in QD/monomer mixtures and photopolymerized to create luminescent fibers and woven textiles. Mechanical deformation and washing resistance were demonstrated in air and underwater.

Key Findings

- Uniform dispersion and strong interactions: XRD/TEM showed 10 nm cubic CsPbBr3 QDs uniformly dispersed; CsPbBr3 peaks vanished in composites, indicating encapsulation. Confocal PL confirmed uniformity. XPS F 1s shifted by 0.3 eV (688.4 to 688.1 eV) upon QD incorporation, and 19F SSNMR CF3 peak shifted from −77.1 to −69.5 ppm, evidencing ion-dipole interactions. AFM revealed much smoother composite films (Rq 0.26 nm) versus pristine QDs (Rq 13.6 nm).

- Mechanical performance: TFE-HF-QD1.0 stretched to 1300% with fracture stress 1.8 MPa; Young’s modulus ~29 MPa; fracture energy ~30 kJ m−2. Variants: QD1.2 reached 3.0 MPa but 950% strain; QD0.8 and QD0.6 exhibited 2200% and 3200% strain but 1.2 and 0.5 MPa stress, respectively. The composite lifted a 4 kg load with a small strip. Elastic behavior demonstrated by E′ > E″ near room temperature, stable cyclic loading, recoverability after large strain, rate-dependent stiffness typical of supramolecular rubbers.

- Optical properties: Bright green emission with PL peak at 521 nm; narrow FWHM 19 nm; CIE (0.1009, 0.7266). Average PL lifetime initially ~20.59 ns (tri-exponential components: 1.67 ns 44.49%, 9.62 ns 36.88%, 88.02 ns 18.63%). Emission remained uniform under bending, twisting, and stretching up to 1300% strain.

- Environmental stability: After 1 month immersion in water, acid (pH 1), base (pH 13), and salty seawater, stress–strain curves remained essentially unchanged. Water contact angle ~124°, reflecting fluorinated hydrophobicity. PL intensity and normalized PLQY remained stable over 1 month across all solutions; initial PLQY increases attributed to water passivation. Average PL lifetime increased to ~43.19 ns after water aging, indicating reduced surface defects. The composite withstood hexane immersion for 2 weeks (free-standing, emissive), whereas SEBS degraded to a sticky gel.

- Self-healing: Autonomous self-healing at ambient conditions without external stimuli. In air: η ~37.65% after 6 h; ~55.00% after 24 h; elasticity recovered. Aging delay before rejoining (6–24 h) had minimal impact on healing efficiency. Underwater and in harsh aqueous environments (salty, pH 1, pH 13), samples healed and could be stretched several-fold after 24 h. At 40 °C, healing efficiency approached ~100% after 24 h.

- Mechanism: Dielectric spectroscopy showed segmental relaxation times from ~1 s to 10−4 s between 20–50 °C, supporting fast chain diffusion aiding healing. XPS of fractured interfaces showed CF3, CF2, C–F, C=O, C–O, C–C components; AFM cohesion force at fractured interface (~29.5–31.5 nN) was about twice that of the intact surface, consistent with abundant dipole-dipole interactions at the interface. 19F SSNMR indicated CF3 mobility restriction upon damage (reduced F2/(F1+F3) area ratio from 0.83 to 0.40) and recovery after healing (0.85). Proposed mechanism involves dipole-driven interfacial interactions, chain conformational changes, and hydrophobic bridging enabling underwater self-healing.

- Applications: Large-area luminescent plates (10 × 10 × 1 cm) and luminescent cotton fibers/textiles (20 × 10 cm) were fabricated by simple dip-coating and photopolymerization, retaining emission under deformation and after hand-washing, suitable for underwater wearable displays and communication.

Discussion

The study demonstrates that designing a fluorinated elastomer with high CF3 dipole density enables strong ion-dipole interactions with positively charged perovskite QDs, ensuring uniform dispersion and suppressing aggregation. The hydrophobic, chemically robust C–F rich backbone provides exceptional environmental resistance in water, acid, base, and saline, preserving both mechanical and optical properties over extended immersion. The dynamic dipole-dipole network, combined with low Tg and fast segmental dynamics, underpins autonomous self-healing in air and underwater, with enhanced rates at modestly elevated temperatures. These outcomes address the central challenge of integrating perovskite QDs into a stretchable, tough, and stable matrix suitable for marine wearable/stretcheable optoelectronics, surpassing limitations of conventional polymer matrices and organogels. The material’s mechanical robustness (high strain and fracture energy), narrow-band high-purity emission, and scalable processing into fibers and textiles further substantiate its relevance for durable aquatic devices and displays.

Conclusion

An all-dipole fluorinated elastomer (TFE-HF) compatibilized with CsPbBr3 QDs yields a transparent, tough, and highly stretchable luminescent composite that autonomously self-heals in air and underwater. Strong ion-dipole and dipole-dipole interactions ensure uniform QD dispersion and dynamic bonding for self-repair, while the fluorinated backbone confers exceptional stability across harsh aqueous environments (pH 1 to 13, saline) for at least a month without significant mechanical or optical degradation. The composite maintains bright, narrow green emission under large deformations and can be fabricated into large-area plates and washable luminescent textiles via simple photopolymerization and dip-coating. These attributes position the material as a promising platform for aquatic wearable/stretchable displays and water-resistant optoelectronic devices. Future work could explore long-term environmental durability under continuous illumination, broader color gamut via different perovskite compositions, lead-free alternatives, and device-level integration.

Limitations

Related Publications

Explore these studies to deepen your understanding of the subject.