Chemistry

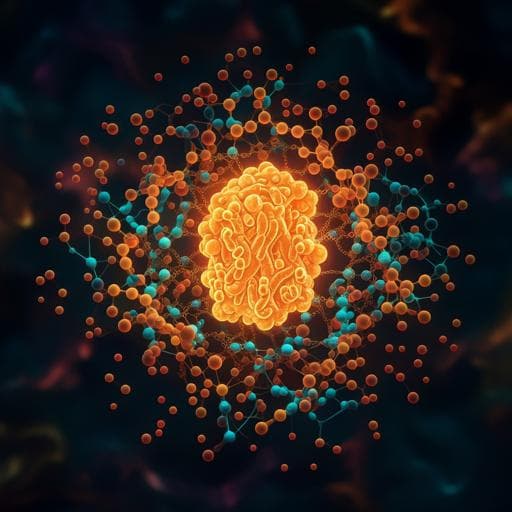

Structure- and computational-aided engineering of an oxidase to produce isoeugenol from a lignin-derived compound

Y. Guo, L. Alvigini, et al.

Discover how researchers engineered a bacterial eugenol oxidase to effectively convert lignin-derived 4-n-propylguaiacol into isoeugenol, a sought-after flavor molecule. This exciting study led by Yiming Guo and a team from the University of Groningen and University of Pavia highlights innovative mutations that enhance enzyme stability and activity for scalable production. Dive into the world of biocatalysis!

Related Publications

Explore these studies to deepen your understanding of the subject.