Environmental Studies and Forestry

S-ZVI@biochar constructs a directed electron transfer channel between dechlorinating bacteria, *Shewanella oneidensis* MR-1 and trichloroethylene

H. Lyu, H. Zhong, et al.

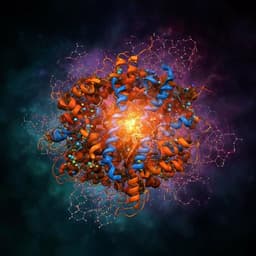

Discover an innovative chem-bio hybrid process that leverages sulfurized micron zero-valent iron and biochar composites to achieve remarkable trichloroethylene degradation. This advanced system, developed by researchers Honghong Lyu, Hua Zhong, Zhilian Li, Zhiqiang Wang, Zhineng Wu, and Jingchun Tang, demonstrates an impressive 96.5% TCE removal efficiency, significantly surpassing traditional methods!

~3 min • Beginner • English

Introduction

Trichloroethylene (TCE) is a widely used chlorinated solvent whose persistence and toxicity necessitate effective remediation strategies. Conventional chemical reduction with zero-valent iron (ZVI) suffers from limitations including passivation, aggregation, hydrogen evolution with poor electron utilization, and short service life. Anaerobic bioremediation by dechlorinating bacteria (DB) can completely dechlorinate TCE but often lacks sufficient electron donors/nutrients and proceeds slowly. To overcome the shortcomings of standalone chemical or biological approaches, this study investigates a synergistic system that enhances electron transfer among materials, microorganisms, and pollutants. Sulfurized ZVI (S-ZVI) improves electron transfer and selectivity for hydrophobic pollutants but still aggregates and passivates. The authors hypothesize that compositing S-ZVI with conductive biochar (S-ZVI@biochar) and coupling with Shewanella oneidensis MR-1 (an iron-reducing bacterium) and a DB consortium can construct a directed electron transfer channel, improve electron efficiency, regulate the microbial community, and recycle iron, thereby enabling long-term and efficient TCE dechlorination. The objectives were to: (1) assess how biochar enhances S-ZVI electron transport and dechlorination; (2) elucidate electron transfer among S-ZVI@biochar, microbes, and TCE; and (3) verify long-term remediation performance of the coupled system.

Literature Review

Multiple strategies to modify ZVI have been reported: surfactant modification to improve dispersion but potentially block active sites; elemental doping (nonmetals like N, P; metals like Cu, Pd, Ni). N and P can improve conductivity or surface properties but may introduce undesired reactions or complexity. Sulfurization yields FeSx on ZVI surfaces, enhancing electron transfer, reducing water corrosion, and increasing hydrophobic interactions with organics, thereby improving selectivity and dechlorination of TCE. However, S-ZVI can still aggregate and lose reactive sites. Coupling iron materials with microbes improves outcomes: ZVI with dehalogenators, iron-reducing bacteria (IRB) such as Shewanella with DB, and biochar to support microbial colonization and act as an electron shuttle. Prior works showed increased TCE removal when combining ZVI with microbes (e.g., CS@ZVI + BL5 increased TCE degradation from 78.68% to 99.75%; mZVI with autotrophic hydrogen bacteria achieved 75% removal in 20 days vs. lower for mZVI alone). Biochar can shorten time to complete removal (e.g., 10 mg/L TCE from 330 h to 150 h) and nZVI/BC reached 100% removal after biostimulation. Shewanella with Dehalococcoides shortened complete dechlorination from 24 to 16 days. Nonetheless, mechanisms for enhanced electron transfer in coupled chem-bio systems remain under-explored, motivating the current work.

Methodology

Materials and microorganisms: Analytical-grade chemicals were used. mZVI (400 mesh) was sourced commercially. TCE and dechlorination products standards (cis-DCE, trans-DCE, 1,1-DCE, VC) were procured. MES buffer (50 mM, pH 6) was prepared. Dechlorinating bacteria (DB) were enriched from TCE-contaminated soil (Binhai New Area, Tianjin) by serial transfers in anaerobic medium with 30 mg/L TCE. The resulting consortium included genera such as Pseudomonas, Delftia, Comamonas, Paraclostridium, Tessaracoccus, Stenotrophomonas, Paenibacillus, Acidovorax, Clostridium, and Paeniclostridium. Anaerobic medium contained salts, trace elements, Se/W, TES buffer, sodium lactate, Na2S·9H2O, L-cysteine, NaHCO3, DL-dithiothreitol; supplemented with sodium acetate (700 mg/L) and VB12 (4 µg/L). Shewanella oneidensis MR-1 was obtained commercially, cultured anaerobically in LB (30 °C), harvested, washed, and resuspended in sterile saline.

Preparation of biochar and S-ZVI@biochar: Pine wood chips were pyrolyzed under N2 at 600 °C for 2 h (5 °C/min ramp) to yield biochar. S-ZVI was prepared by sulfidating mZVI with sodium dithionite (S:Fe molar 1:10) in N2-purged MES for 12 h, washing, and freeze-drying. S-ZVI@biochar was produced by ball milling S-ZVI with biochar (mass ratio 3:1) at 300 rpm for 12 h under N2 with 3 mm stainless-steel balls.

Batch experiments: Conducted in 20 mL brown vials at 30 °C in the dark. Unless stated, DB was in log phase; sodium acetate 700 mg/L was added; initial TCE 10 mg/L; total liquid volume 7 mL anaerobic medium. Material dosage: 0.5 g/L for ZVI, S-ZVI, S-ZVI@biochar. In DB + material systems: DB inoculum 0.7 mL. In DB + MR-1 + material systems: DB 0.7 mL; MR-1 at OD600=0.1 added at 1:250 (v/v) of final reaction volume; material 0.5 g/L. Controls included sterile medium with TCE.

Analytical methods: TCE and products (cis-DCE, trans-DCE, 1,1-DCE, VC, acetylene, ethylene) were quantified by headspace GC-FID (Agilent 7890B; GS-Q column; 80 °C equilibration; inlet 200 °C; split 10:1; N2 25 mL/min; temperature program 50 °C 7 min then 20 °C/min to 230 °C, hold 10 min). External calibration with a 5-point curve; TCE detection range 0.1–10 mg/L. Total Fe by ICP-AES; dissolved Fe(II) by phenanthroline method; H2 by GC-TCD; pH and ORP by meters; microbial growth by OD600. Solids after 30 days were freeze-dried and characterized by SEM/EDS, XPS (Al Kα), and XRD (Rigaku Ultima IV). Electrochemical properties (EAC, EDC, CV, GCD) were measured to assess electron transfer capacity.

Metagenomics: Samples collected at start and after 30 days for DB, DB + S-ZVI@biochar, and DB + MR-1 + S-ZVI@biochar. DNA extracted (Tengen DP705), quantified (Qubit), integrity checked (1% agarose). Libraries were prepared (VAHTS Universal Plus DNA Library Prep Kit), QC’d, and sequenced on Illumina NovaSeq 6000. Reads were filtered (fastp), assembled (MEGAHIT, contigs >300 bp), evaluated (QUAST), genes predicted (MetaGeneMark), and de-replicated (MMseqs2, 95% similarity, 90% coverage).

Key Findings

- Performance: DB + MR-1 + S-ZVI@biochar achieved the highest TCE removal, 96.5% at 30 days, 3.7× higher than bare ZVI. S-ZVI@biochar alone removed 80.8% (14 d) and 88.5% (30 d). DB alone removed 47.6% (14 d) and 55.5% (30 d). ZVI alone removed 20.6% (14 d) and 26.0% (30 d); S-ZVI 31.0% (14 d) and 37.8% (30 d).

- Synergy: Coupling DB with materials accelerated removal. DB + S-ZVI improved TCE removal by 81.4% over S-ZVI at 30 d; DB + S-ZVI@biochar improved by 5.7% over S-ZVI@biochar. Adding MR-1 further increased removal: +16.3% (DB + S-ZVI) and +3.2% (DB + S-ZVI@biochar) at 30 d. DB + MR-1 + S-ZVI@biochar reached 90.6% removal by day 14 versus 92.1% by day 21 for DB + S-ZVI@biochar.

- Electron transfer properties: S-ZVI@biochar exhibited high electrochemical capacity: EAC 38.58 mmol e/g, EDC 0.43 mmol e/g (ETC 39.01 mmol e/g), and GCD 4.22 F/g, exceeding ZVI (EAC 12.25; EDC 0.12; GCD 2.27 F/g) and S-ZVI (EAC 14.32; EDC 0.39; GCD 3.45 F/g). CV showed combined redox features of S-ZVI and biochar.

- System chemistry: S-ZVI@biochar produced more H2 and drove pH increases and ORP decreases more than ZVI or S-ZVI. In coupled systems, H2 rose rapidly to day 14, then decreased as microorganisms consumed H2 during active dechlorination; later it increased as acceptor (TCE) diminished. ORP trends indicated greater reducing conditions in DB + MR-1 + S-ZVI@biochar.

- Iron cycling: S-ZVI@biochar sustained Fe(II) production longer than S-ZVI. In DB + MR-1 + S-ZVI@biochar, the solid-phase Fe(II)/Fe(III) ratio increased from 0.4782 (DB + S-ZVI@biochar) to 0.6690, evidencing MR-1-mediated bioreduction of Fe(III) to Fe(II). MR-1 promoted FeS2 formation and increased green rust/FeS-related phases; XRD/SEM indicated more pyrite spheres with MR-1.

- Material dispersion and biocompatibility: Biochar prevented S-ZVI aggregation, improved suspension/mobility, provided microbial attachment niches, and enhanced chem-bio co-migration. SEM showed biofilm growth on S-ZVI@biochar surfaces in both anaerobic and LB media.

- Surface chemistry: XPS C1s showed decreases in oxygen-containing groups (e.g., C=O) after reactions, consistent with biochar acting as an electron shuttle. O1s spectra indicated lower O2-related features with MR-1, aligned with increased FeS and less green rust.

- Microbial ecology: Metagenomics indicated that in DB-only systems after 30 d, Delftia dominated under high TCE and contributed to dechlorination. With S-ZVI@biochar, Pseudomonas became dominant, enhancing dechlorination potential. Alpha diversity decreased with TCE, increased in abundance but decreased in diversity with S-ZVI@biochar and further with MR-1; Pseudomonas proportion rose. Beta-diversity analyses (PCoA, NMDS, UPGMA) showed distinct communities; DB + S-ZVI@biochar and DB + MR-1 + S-ZVI@biochar were similar to each other but distinct from DB alone.

- Pathways and products: DB and DB + MR-1 produced cis-DCE and VC via hydrogenolysis. S-ZVI and S-ZVI@biochar produced ethylene and ethyne via β-elimination; S-ZVI@biochar yielded higher ethylene (5.5 µmol/L) and ethyne (15.7 µmol/L) at 30 d than S-ZVI (2.2 and 2.3 µmol/L). S-ZVI@biochar maintained dechlorination beyond 21 d whereas S-ZVI activity waned. Relative KEGG pathway abundances for chloroalkane/alkene degradation increased by 4.8% (DB 30 d), 13.0% (DB + S-ZVI@biochar 30 d), and 17.6% (DB + MR-1 + S-ZVI@biochar 30 d) versus DB at day 0.

- Overall: Biochar constructed an electron transport channel connecting S-ZVI-derived electrons to DB/MR-1 and TCE, improved electron utilization, regulated microbial communities (favoring dechlorinators), and enabled iron recycling, culminating in long-term high-efficiency TCE removal in anaerobic conditions.

Discussion

The study addressed the central challenge of low electron transfer efficiency in both chemical and biological TCE remediation by engineering S-ZVI@biochar to serve as a conductive scaffold and electron shuttle between materials, microbes, and TCE. Enhanced electrochemical properties (high EAC/EDC and capacitance) of S-ZVI@biochar enabled more efficient electron delivery from ZVI cores through FeSx shells and biochar to microbial and chemical acceptors. Biochar improved S-ZVI dispersion, reduced passivation impacts, and provided niches for DB and MR-1, enhancing co-migration and contact, which is critical in dynamic groundwater environments. MR-1 mediated iron cycling by reducing Fe(III) to reactive Fe(II), raising the Fe(II)/Fe(III) ratio and forming FeS2 that participates in dechlorination, thereby extending material service life and sustaining reducing conditions (lower ORP). Community shifts toward Pseudomonas in biochar-containing systems and increased KEGG dechlorination pathway representation corroborated enhanced biological dechlorination, while product distributions confirmed concurrent microbial hydrogenolysis and chemical β-elimination/hydrogenolysis. The coupling of DB, MR-1, and S-ZVI@biochar thus constructed a directed electron transfer channel, improving kinetics, robustness, and longevity of TCE removal compared to standalone ZVI, S-ZVI, or microbial systems.

Conclusion

This work demonstrates a chem-bio hybrid remediation system wherein S-ZVI@biochar, dechlorinating bacteria (DB), and Shewanella oneidensis MR-1 establish a directed electron transfer channel, leading to superior and sustained TCE removal (up to 96.5% at 30 days). Biochar confers improved dispersion, mobility, and electrochemical properties, acting as an electron shuttle and microbial support, while MR-1 facilitates iron cycling (Fe(III) to Fe(II)), enhancing dechlorination via both microbial hydrogenolysis and chemical β-elimination/hydrogenolysis. The system adjusts microbial community composition to favor dechlorinators (e.g., Pseudomonas) and maintains a strong reducing environment with effective H2 utilization. These insights provide a basis for designing sustainable in situ remediation strategies for chlorinated solvents by integrating modified iron materials, conductive carbon supports, and functional microbial consortia. Future research could focus on scaling to flow-through/field conditions, optimizing material-to-biomass ratios and dosing strategies, longevity under variable geochemistry, and evaluating performance with co-contaminants and natural organic matter.

Limitations

Related Publications

Explore these studies to deepen your understanding of the subject.