Engineering and Technology

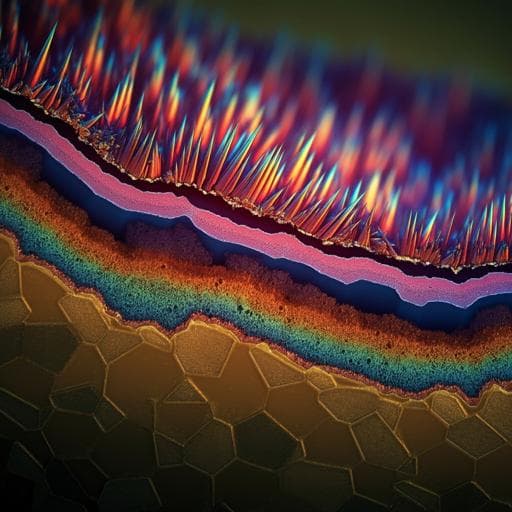

Nanoscopic and in-situ cross-sectional observations of Li-based conversion coating formation using liquid-phase TEM

A. Kosari, F. Tichelaar, et al.

This research, conducted by A. Kosari, F. Tichelaar, P. Visser, P. Taheri, H. Zandbergen, H. Terryn, and J. M. C. Mol, utilizes liquid-phase transmission electron microscopy to unveil the intricate steps of lithium-based conversion coatings on aluminum. Discover a revolutionary approach that reveals a fascinating multi-stage process of surface transformation.

Related Publications

Explore these studies to deepen your understanding of the subject.