Engineering and Technology

Miniaturized and untethered McKibben muscles based on photothermal-induced gas-liquid transformation

W. Ai, K. Hou, et al.

The study addresses the challenge of miniaturizing pneumatic artificial muscles for operation in confined spaces without external pumps, valves, or tethers. While soft actuators can be powered pneumatically, electrically, magnetically, or via responsive materials, pneumatic systems typically require bulky ancillary hardware that impedes remote, miniature applications. Prior thin McKibben efforts remain constrained by energy delivery and control valves. To overcome these limitations, the authors leverage liquid–gas phase transition as a wireless pneumatic working medium activated by light, enabling remote heating, rapid pressure generation, and actuation without external connections. The purpose is to design a compact, fiber-reinforced, light-driven artificial muscle capable of substantial axial elongation and bending with reliable sealing, reduced leakage, and reusability, expanding applicability to rescue, exploration, and tight environments.

Existing soft actuators employ liquid crystal polymers, hydrogels, electroactive polymers, and shape-memory alloys, with diverse activation modes (pneumatic, electrical, magnetic). Pneumatic artificial muscles deliver high output and fast response but suffer from reliance on pumps, valves, and tubing, complicating miniaturization and wireless control. Thin McKibben developments and miniature pneumatic actuators progress are limited by energy delivery and control mechanisms. Liquid–gas phase-change actuators have emerged to enable untethered operation by embedding phase-change materials in balloons or films, heated electrically, magnetically, or optically, eliminating pumps and pipes. However, the use of highly permeable elastomers as carriers for low-boiling liquids often leads to leakage, undermining durability. Light-controlled small actuators have been demonstrated but typically produce simple bending via asymmetric forces rather than controlled axial elongation in fiber-reinforced geometries. The present work integrates light control with pneumatic fiber-reinforcement and introduces a fabrication method that improves sealing and enables millimeter-scale McKibben-like functionality.

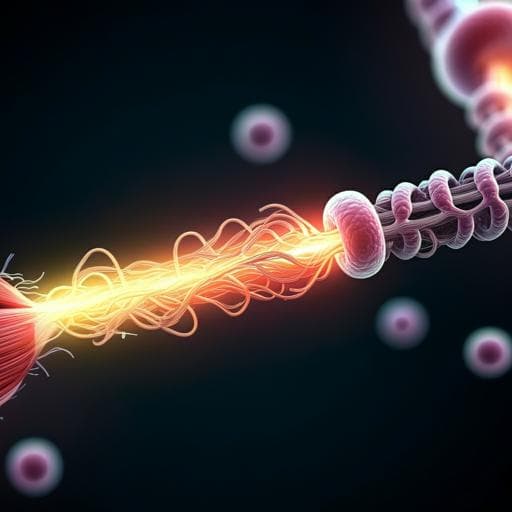

Design and materials: A cylindrical elastomeric actuator was fabricated by mold editing using a polyurethane acrylate prepolymer (H810), nanometer-sized carbon powder (photothermal absorber), and a low-boiling-point liquid (1,1,1,4,4,4-hexafluorobutene, boiling point ~33 °C). The prepolymer mixture was mechanically agitated at 235 rpm to disperse the liquid as droplets (average ~2.9 µm) and introduced into a transparent cylindrical mold. Photocuring mechanism: The mixture was UV-cured. Dispersed carbon nanoparticles blocked UV penetration, preventing complete curing in the core and forming a central fluid-filled cavity while the outer shell cured, producing an integrated, sealed actuator without post-injection and sealing steps. Radial constraint: A PTFE film with single-oriented fibers was wrapped around the cured cylinder. To prevent the PTFE from detaching (low adhesion), an outer layer of prepolymer was applied and UV-cured to secure the PTFE. Fiber orientation perpendicular to the actuator axis constrained radial expansion and promoted axial elongation (McKibben-like behavior). Configurations: Orientation of the PTFE fibers and placement of limiting layers enabled different deformation modes: axial elongation (fibers perpendicular to axis), C-shaped bending (asymmetric limiting layer), and S-shaped bending (top and bottom limiting layers near end fittings). Optimization studies: Effects of nanocarbon content (0–0.20 wt%) at fixed liquid content (23 wt%) and liquid content (≤25 wt%) were characterized for maximum axial elongation. Stress–strain behavior of films with different carbon loadings was measured. Temperature–elongation response under light was recorded to determine onset and equilibrium behavior. Characterization and testing: Elongation was recorded via digital imaging and analyzed in ImageJ. Stress–strain curves were obtained using universal testing machines (Instron 5566/3365). Infrared imaging monitored surface temperature. Blocking (unidirectional) force was measured by placing a cylindrical actuator (l = 30 mm, d = 9 mm) in a PMMA cylinder to eliminate radial expansion and connecting to a force gauge (MARK-10 M5-2), varying the blocking strain (0–50%). Light sources: Xenon lamp (power densities typically 100–150 mW/cm²; 120 mW/cm² for cycling tests). Reusability was assessed by soaking actuators in the low-boiling liquid to replenish lost working fluid after cycling-induced leakage. Device demonstrations: A miniature walking device combined a 2 mm × 5 mm actuator (15.7 mm³) with a laser-cut exoskeleton (20 mm × 3 mm pre-bend). An earthworm-inspired device comprised two hemispherical elastomer feet (d = 9 mm) and a central actuator body (d = 9 mm, l = 34.8 mm) to crawl inside a tube (ID 14 mm) under moving light. A three-finger gripper used three 8 cm-long C-bending actuators mounted to a laser-cut support to grasp and release a ping-pong ball under light.

- Miniaturization and sealing: The mold-editing UV-curing strategy using carbon-mediated UV attenuation formed an internal fluid cavity without injection/sealing, improving tightness and enabling a minimal actuator volume of 15.7 mm³ (d = 2 mm, l = 5 mm).

- Radial constraint effect: Without PTFE wrapping, radial elongation reached ~63% and axial ~17%; with PTFE, radial elongation reduced to ~13% and axial increased to ~47%, effectively shifting deformation from radial to axial (approx. 50% reduction in radial and 30% increase in axial elongation, as reported).

- Composition optimization: At 23 wt% liquid content, increasing carbon from 0.11 to 0.17 wt% raised maximum axial elongation to 54.6% (optimal). Above 0.17 wt% carbon, reduced air-tightness lowered elongation due to looser crosslinking and thinner films. Increasing liquid content elevated expansion up to ≈60% elongation when ≤25 wt%; at 25 wt% samples were damaged at peak elongation, so 23 wt% liquid was selected for robustness.

- Thermal–mechanical response: Under 100 mW/cm² light, elongation began when average surface temperature reached ~50 °C and approached equilibrium by ~460 s. IR imaging confirmed heating under illumination and cooling-driven recovery.

- Cycling and reusability: With 19 wt% liquid, actuators performed 20 reversible elongation cycles over 68 min under 120 mW/cm² with average elongation ~36.4%, showing gradual decline attributed to gas leakage; soaking in the low-boiling liquid restored performance.

- Blocking force: In a confined cylinder (eliminating radial expansion), the maximum unidirectional force for an unstrained sample was ~6.3 N (sample mass ~2.4 g).

- Applications: A fingertip-scale walking device advanced ~3.3 mm over four light on/off cycles on a flat surface (150 mW/cm²). An earthworm-like device executed multiple steps inside a 14 mm-ID tube, achieving cumulative displacement of ~5 cm. A three-finger light-driven gripper (8 cm fingers) grasped and released a ping-pong ball. A light-controlled thruster shifted a 100 g weight by 2.1 cm; measured maximum static friction ~0.2 N.

The results demonstrate that light-activated liquid–gas phase transition within a fiber-reinforced elastomer can produce substantial axial elongation and functional bending at millimeter scale without external pumps or tethers, directly addressing the challenge of miniaturizing pneumatic artificial muscles for confined environments. The PTFE fiber wrap effectively converts pressure-driven radial expansion into axial stroke, akin to McKibben mechanics, while the carbon-filled UV-curable prepolymer improves sealing by forming an internal cavity in situ. Optimization identified a balance between photothermal loading (carbon content) and membrane integrity to maximize elongation without compromising airtightness. Thermal measurements clarify the actuation onset (~50 °C) and timescale to equilibrium. Although cyclic performance is affected by leakage and interfacial constraints, recharging via soaking restores actuation, supporting sustainable use. Demonstrations of untethered crawling on a plane, locomotion in a tube, and gripping validate the actuator’s relevance for robotics in tight spaces and show versatility in deformation modes via structural design.

This work introduces a miniaturized, untethered, light-driven fiber-reinforced artificial muscle that uses photothermal-induced liquid–gas transformation within a UV-cured, sealed elastomeric cylinder constrained by PTFE fibers. The design achieves strong axial elongation, programmable bending, millimeter-scale form factor (15.7 mm³), and reusability by fluid replenishment. Applications in planar walking, in-pipe locomotion, and gripping demonstrate functional versatility for soft robotics in confined environments. Future efforts may pursue further miniaturization and performance enhancements via microcapsules, electrospinning, and colloidal assembly, improved interfacial fixation of PTFE for stability, and optimized light delivery and materials to reduce leakage and improve cycling durability for biomedical and exploratory applications.

- Stability of the PTFE constraint relies on adhesion of a cured prepolymer outer layer; interfacial stress during actuation can exceed the holding capacity, causing local debonding, loss of elongation, unintended bending, or device damage.

- Airtightness degrades with higher carbon content due to looser crosslinking and thinner films; repeated cycling loosens structure and promotes gas leakage, reducing elongation until replenished by soaking.

- High liquid contents (~25 wt%) can cause specimen damage at peak elongation; a trade-off exists between stroke and durability.

- Film thickness non-uniformity due to handheld UV curing may affect reproducibility; improved curing (e.g., ring UV) is suggested.

- In-tube locomotion exhibited displacement losses due to delayed segmented illumination and friction; coordination of light timing and anchoring needs refinement.

- Actuation equilibrium time (~460 s at 100 mW/cm²) indicates relatively slow thermal response compared with pump-driven pneumatics.

Related Publications

Explore these studies to deepen your understanding of the subject.