Introduction

The escalating discharge of organic contaminants from industrial, agricultural, and domestic sources poses a significant threat to aquatic ecosystems and human health. Current methods for removing these contaminants, such as adsorption, advanced oxidation processes, and membrane filtration, each have limitations. Adsorption, while cost-effective and easy to operate, often suffers from selectivity issues, only effectively removing certain contaminants. Advanced oxidation processes, although non-selective, can be energy-intensive, time-consuming, and may lead to secondary pollution due to the formation of degradation byproducts. Membrane filtration, while efficient for continuous separation, can be expensive and prone to fouling. This study addresses these limitations by proposing a novel extraction method using magnetic ethyl acetate microdrops.

Literature Review

The paper reviews existing water purification methods for organic contaminants, highlighting the limitations of adsorption, advanced oxidation, and membrane filtration. Adsorption methods, while cost-effective, are often selective, only removing specific contaminants. Examples cited include the removal of bisphenol A and ibuprofen using amyloid fibrils aerogel, phytochrome and acidic blue with biochar, and sulfachloropyridazine with UiO-66 metal-organic frameworks. Advanced oxidation processes, although non-selective, suffer from high energy and chemical consumption, increased processing time, and higher costs. Moreover, secondary pollution from incomplete degradation is a concern. Membrane filtration, employing materials like graphene oxide, MOFs, and MXene, offers fast and continuous removal but faces challenges related to high preparation costs and membrane fouling. The authors position their proposed extraction method as a potential solution to these challenges.

Methodology

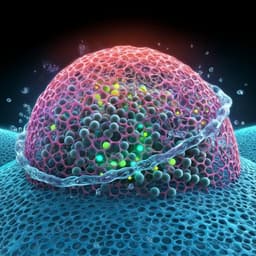

The researchers fabricated magnetic ethyl acetate microdrops (Fe3O4@KCC-1@EA) by coating Fe3O4 nanoparticles with a silica shell (KCC-1) and then loading ethyl acetate onto the surface of the superhydrophobic/superoleophilic Fe3O4@KCC-1 nanospheres. The KCC-1 shell, a mesoporous silica with a dendritic fibrous structure, provides high surface area and mechanical stability. The magnetic Fe3O4 core allows for magnetic separation of the microdrops. The superhydrophobic/superoleophilic nature of the Fe3O4@KCC-1 nanospheres ensures the preferential absorption of ethyl acetate, which then acts as the solvent to extract organic contaminants from the water. The synthesis involved several steps: (1) coating Fe3O4 nanoparticles with a SiO2 layer using the Stöber method, (2) creating a KCC-1 shell, (3) modifying the Fe3O4@KCC-1 nanospheres with n-hexyltrimethoxysilane to enhance superhydrophobicity/superoleophilicity, and (4) loading ethyl acetate. Characterization of Fe3O4@KCC-1 nanospheres involved scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), Fourier transform infrared spectroscopy (FT-IR), thermogravimetric (TG) analysis, and magnetism analysis. The extraction efficiency of bisphenol A (BPA) and other organic contaminants (phenol, resorcinol, p-phthalic acid, and 4-nitrobenzaldehyde) was evaluated by measuring their concentrations before and after extraction using high-performance liquid chromatography (HPLC). The influence of pH, stirring rate, stirring time, and temperature on extraction efficiency was investigated. The reusability of the Fe3O4@KCC-1@EA microdrops was assessed through multiple cycles of extraction, and the total organic carbon (TOC) content in the water after extraction was measured to evaluate secondary pollution.

Key Findings

The study successfully synthesized magnetic Fe3O4@KCC-1@EA microdrops with high efficiency in removing organic contaminants from water. The ethyl acetate shell of the microdrops proved effective in extracting bisphenol A (BPA) from the water phase, achieving a removal rate exceeding 98% under optimized conditions (pH 4, 500 rpm stirring rate, 1-minute stirring time, and 30°C). The optimal extraction efficiency for BPA was achieved at a pH of 4. A decrease in extraction efficiency was observed when the pH was increased above 8 due to increased ionization of BPA. Increasing the stirring rate beyond 500 rpm led to a decrease in efficiency, potentially due to boundary layer effects and ethyl acetate evaporation. A stirring time of 1 minute was optimal; longer times led to decreased efficiency due to ethyl acetate evaporation. The extraction efficiency slightly increased at 30 °C, compared to 20 °C, but decreased at higher temperatures. Notably, the Fe3O4@KCC-1@EA microdrops demonstrated excellent reusability, maintaining high extraction efficiency after five cycles. The method also proved effective for other organic contaminants, including phenol, resorcinol, p-phthalic acid, and 4-nitrobenzaldehyde, with removal efficiencies above 90%. The residual TOC concentration in the treated water remained low, indicating limited secondary pollution from the extraction process. The carrying capacity of the superhydrophobic/superoleophilic Fe3O4@KCC-1 for ethyl acetate was measured to be 2.67 mL·g-1.

Discussion

The findings demonstrate the efficacy of the novel magnetic ethyl acetate microdrop method for removing organic contaminants from water. The method successfully addresses the limitations of existing technologies by combining high extraction efficiency, easy magnetic separation, and good reusability. The high removal rate for BPA and other organic pollutants highlights the potential of this method for water purification. The low residual TOC concentration suggests that this method introduces minimal secondary pollution. The successful recycling of the Fe3O4@KCC-1@EA microdrops reduces costs and improves sustainability. However, the study mainly focuses on laboratory-scale experiments, and further research is needed to assess the feasibility and scalability of this method for real-world applications.

Conclusion

This research successfully developed magnetic Fe3O4@KCC-1@EA microdrops for efficient extraction of organic contaminants from water. The method offers advantages in terms of efficiency, reusability, and reduced secondary pollution. Future studies should focus on optimizing the process for various contaminant mixtures, evaluating its performance in real-world scenarios (e.g., treating lake or river water), and exploring alternative organic solvents with higher extraction efficiency and lower aqueous solubility.

Limitations

The study was primarily conducted at the laboratory scale, and larger-scale applications might present challenges related to solvent consumption, contaminant mixture extraction efficiency, and the efficient collection of microdrops from large water bodies. The selection of ethyl acetate as the organic solvent could also be further optimized, exploring alternatives that may be more effective for different contaminants and possess lower aqueous solubility, minimizing potential secondary pollution.

Related Publications

Explore these studies to deepen your understanding of the subject.