Chemistry

Laser-induced nitrogen fixation

H. Wang, R. R. Seemakurthi, et al.

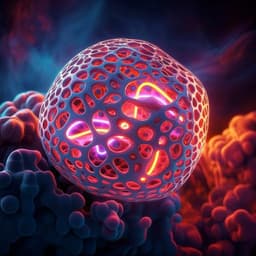

This groundbreaking research by Huize Wang and colleagues presents a revolutionary method for synthesizing ammonia through laser-induced nitrogen fixation, achieving impressive results at ambient conditions. With a yield rate of 30.9 micromoles per second per square centimeter using a CO2 laser, this innovative technology paves the way for local ammonia production and novel chemical processes.

Playback language: English

Related Publications

Explore these studies to deepen your understanding of the subject.