Engineering and Technology

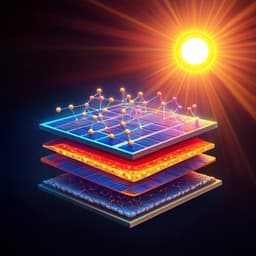

Interpenetrating interfaces for efficient perovskite solar cells with high operational stability and mechanical robustness

Q. Dong, C. Zhu, et al.

Perovskite solar cells (PSCs) have rapidly emerged as a disruptive photovoltaic technology due to high power conversion efficiencies (up to 25.5%), favorable optoelectronic properties (high absorption, long carrier diffusion lengths, defect tolerance), and low-temperature solution processability enabling flexible devices. Despite the promise, stability remains a core challenge, hindering deployment. Interface engineering is a promising route to enhance efficiency and stability via energy-level alignment, improved contacts, defect suppression, reduced hysteresis, and tailored surface properties. However, many approaches add extra layers or surface modifiers, potentially complicating processing and compromising mechanical integrity, especially under long-term illumination and cyclic bending for flexible devices. This work addresses these issues by proposing a holistic, mechanically robust interpenetrating interface between the perovskite absorber and the SnO₂ electron-transporting layer (ETL), formed via a controlled interfacial reaction between a formamidinium halide–incorporated SnO₂ (FI-SnO₂) layer and a perovskite with excess PbI₂. The study aims to demonstrate enhanced efficiency, operational stability, and mechanical robustness, and to elucidate the underlying mechanisms through advanced characterization.

Prior interfacial engineering strategies for PSCs include inserting additional layers (inorganic nanoparticles, polymers, molecules) and chemical surface modifications (functional groups such as thiophene, pyridine; inorganic dopants like Cl⁻ or alkali ions). These methods can improve PCE and stability by optimizing band alignment, contact quality, defect passivation, hysteresis mitigation, and hydrophobicity. Nonetheless, they often require additional processing steps and may introduce mechanically weak, sharp interfaces susceptible to delamination under operation and bending. SnO₂ has been widely adopted as a low-temperature ETL, with prior reports improving electron extraction and stability via compositional or interface modifications. Yet, approaches that simultaneously provide functional benefits and enhanced mechanical integrity are less explored. This work builds on that literature by creating a diffuse, interpenetrating OIHP/SnO₂ interface to maximize both electronic and mechanical robustness.

- ETL synthesis (FI-SnO₂): Formamidinium iodide (FAI) was dissolved into a SnO₂ nanocrystal colloidal solution in isopropanol (IPA), inducing re-growth and more uniform distribution of SnO₂ nanocrystals. Optimized FAI concentration in the SnO₂ sol was 10 mg mL⁻¹ (tested range 2–60 mg mL⁻¹). Films were spin-coated on FTO (or ITO on PEN for flexible devices), annealed at 80 °C for 2 h in air, then UV-ozone treated for 10 min. FI-SnO₂ forms a nanocomposite with SnO₂ nanoparticles dispersed in an FA mixed halide (FAI/FACI) matrix, confirmed by FTIR (C≡N at 1720 cm⁻¹, N–H at 1640 cm⁻¹), XPS (N 1s ~400 eV; I 3d ~620 eV; Cl 2p ~199 eV; Sn 3d shifted to lower binding energy due to interaction with I/Cl). C-AFM mapping showed more uniform conductivity and fewer shunts versus pristine SnO₂.

- Perovskite deposition: A multi-cation/anion precursor with slight excess PbI₂: PbI₂:PbBr₂:CsI:FAI:MABr molar ratio 1.15:0.2:0.05:1.05:0.2 in DMF:DMSO (4:1 v/v). Target composition Cs₀.₀₄(FA₀.₈₄MA₀.₁₆)₀.₉₆Pb(I₀.₈₄Br₀.₁₆)₃. Spin-coating: 1000 rpm 10 s then 6000 rpm 30 s; 250 µL α,α,α-trifluorotoluene dripped 15 s before the end. Anneal 100 °C for 50 min. On FI-SnO₂, excess PbI₂ reacts with FA halide to form an interpenetrating OIHP phase within ETL during anneal.

- Device fabrication: Stack (rigid): Glass/FTO/FI-SnO₂ (or pristine SnO₂)/perovskite/spiro-OMeTAD/Au (60 nm, active area 0.16 cm² evaporated). Flexible devices used PEN/ITO substrates (15 Ω sq⁻¹, 125 µm thick) with analogous stack. Spiro-OMeTAD solution: 72.3 mg in CB with TBP and Li-TFSI additives.

- Characterization: SEM (plan-view and cross-section), AFM and C-AFM (conductive mapping), FTIR (ATR), XPS/UPS (He-I 21.2 eV), TOF-SIMS depth profiling (on glass to avoid FTO Sn signal), TEM/STEM with EDX elemental mapping (FIB-prepared cross-sections), KPFM (AM mode) on device cross-sections under illumination at short-circuit, steady-state PL and time-resolved PL (395 nm excitation), transient photovoltage.

- Photovoltaic testing: J–V with Keithley 2400 under AM 1.5G 100 mW cm⁻² (Newport Oriel Sol3A), scan speed 100 mV s⁻¹, active area defined by 0.096 cm² mask. EQE with Oriel IQE 200B. Stabilized PCE monitored at MPP.

- Stability testing: Unencapsulated devices in N₂-flow sealed holder, MPP bias under continuous one-sun white-LED illumination at ~45 °C (reported 40–45 °C). Mechanical bending of flexible devices with r = 3 mm; cycles: flat → convex → flat → concave → flat; performance measured in ambient (~40% RH, 25 °C). Cross-sectional SEM used to assess interfacial integrity after cycles. Stress estimation used σ = E h / (2r) with E = 17.8 GPa (MAPbI₃ proxy) and h = 125 µm.

- Interpenetrating interface formation: TOF-SIMS depth profiles show a shallower Pb gradient and extended intermixing across the OIHP/FI-SnO₂ interface relative to pristine SnO₂. STEM-EDX mapping reveals Pb distributed within FI-SnO₂ (~95 nm thick vs ~45 nm for pristine), evidencing OIHP infiltration and a diffuse interface.

- Electronic structure: UPS indicates similar Fermi levels (~3.8 eV below vacuum) for FI-SnO₂ and SnO₂, with VBM/CBM for FI-SnO₂ at −8.1 eV/4.2 eV and pristine SnO₂ at −8.3 eV/4.0 eV, yielding a cascade alignment at the OIHP/FI-SnO₂ interface favorable for electron extraction.

- Interfacial potential and carrier dynamics: KPFM under illumination at short-circuit shows a larger CPD drop at OIHP/FI-SnO₂ (≈0.10 V) than at OIHP/pristine SnO₂ (≈0.03 V), with a wider depletion region extending into the OIHP. TRPL shows faster biexponential decay for OIHP/FI-SnO₂ (τ₁ = 1.8 ns, τ₂ = 19.2 ns) vs OIHP/SnO₂ (τ₁ = 2.3 ns, τ₂ = 20.5 ns), consistent with enhanced quenching. Transient photovoltage indicates longer recombination lifetime τr = 72 µs for FI-SnO₂ devices vs 30 µs for pristine SnO₂ devices.

- Photovoltaic performance (rigid): Champion device with FI-SnO₂ achieves PCE up to 22.2% (Voc 1.18 V, Jsc 23.2 mA cm⁻², FF 0.808). Stabilized PCE at MPP: 22.1%. Control (pristine SnO₂) shows PCE 19.7% (forward-scan) and stabilized 18.8%.

- Photovoltaic performance (flexible): On PEN/ITO, champion device reaches PCE 20.1% (reverse), Jsc 22.4 mA cm⁻², Voc 1.15 V, FF 0.782; forward-scan PCE 19.6%. Stabilized PCE 19.8%.

- Operational stability: Under continuous one-sun MPP operation for 1000 h (N₂ flow, ~40–45 °C), FI-SnO₂-based devices retain 82% of initial PCE (initial 21.1%). Control SnO₂ devices exhibit rapid initial decay (72% retention after 400 h).

- Mechanical durability (flexible): With r = 3 mm bending (max stress ~371 MPa), FI-SnO₂ devices retain 85% of initial PCE after 2500 cycles vs 60% for pristine SnO₂. Cross-sectional SEM after 1000–2500 cycles shows delamination at the OIHP/pristine SnO₂ interface, while OIHP/FI-SnO₂ remains intact (only some OIHP cracking under tensile strain).

Creating a diffuse, interpenetrating OIHP/SnO₂ interface enhances both electronic and mechanical integrity compared to a sharp, planar interface. The interfacial reaction between excess PbI₂ in the perovskite and FA halide within FI-SnO₂ forms an OIHP phase inside the ETL, yielding a graded heterojunction with cascade band alignment. KPFM reveals an increased built-in potential and wider depletion region, facilitating exciton separation and electron collection. TRPL and steady-state PL confirm more efficient charge extraction, while transient photovoltage shows reduced recombination. These electronic benefits translate into higher Voc, Jsc, FF, and stabilized PCE in both rigid and flexible devices. Mechanically, the interpenetrating interface resists delamination under compressive peel stresses during bending, preserving device performance over thousands of cycles. The approach addresses the dual challenges of operational stability and mechanical robustness without adding separate interlayers or complex processing, underscoring interface integrity as a key design lever for practical PSCs.

The study introduces a holistic interface design for PSCs by synthesizing an interpenetrating perovskite/SnO₂ ETL interface through a controlled reaction of excess PbI₂ in the perovskite with FA halide in the ETL. Advanced microscopy and spectroscopic analyses confirm interpenetration and a favorable cascade energy alignment, leading to enhanced built-in potential, improved charge separation/collection, and longer carrier lifetimes. Devices achieve high efficiencies (rigid up to 22.2% stabilized 22.1%; flexible up to 20.1% stabilized 19.8%), long-term operational stability (82% retention after 1000 h at MPP), and superior mechanical endurance (85% retention after 2500 bending cycles), outperforming controls with pristine SnO₂ interfaces. This work highlights interface integrity as central to achieving efficient, stable, and mechanically robust PSCs. Future research could generalize this interpenetrating-interface strategy to other ETLs/HTLs and perovskite compositions, optimize reaction control and thickness gradients for large-area scalable processes, evaluate encapsulated devices under varied environmental stressors (humidity/thermal cycling), and integrate into modules for real-world deployment.

- Stability tests were performed on unencapsulated devices under N₂ flow and controlled temperature/light; performance under ambient humidity or damp heat was not reported. - Mechanical bending tests used a specific radius (3 mm) and environmental conditions (~40% RH, 25 °C); broader mechanical stress profiles and long-term outdoor conditions were not assessed. - The elastic modulus used for stress estimation was taken from MAPbI₃ due to unknown E for the specific mixed-cation perovskite, introducing approximation. - The approach was demonstrated with a specific perovskite composition and SnO₂-based ETL; generality to other materials/systems and large-area devices remains to be validated. - Some devices exhibited OIHP cracking under tensile strain, indicating potential constraints under severe deformation even with improved interfacial integrity.

Related Publications

Explore these studies to deepen your understanding of the subject.