Engineering and Technology

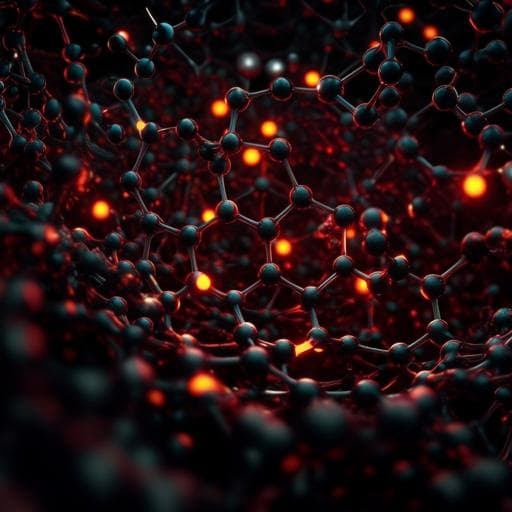

High-speed identification of suspended carbon nanotubes using Raman spectroscopy and deep learning

J. Zhang, M. L. Perrin, et al.

This innovative research led by Jian Zhang and colleagues presents a high-throughput method to swiftly identify suspended carbon nanotubes using advanced Raman imaging and deep learning techniques. With classification accuracies exceeding 90%, this approach promises to enhance quality control in nanomaterial production, paving the way for industrial adoption.

Related Publications

Explore these studies to deepen your understanding of the subject.