Engineering and Technology

High-sensitivity nanophotonic sensors with passive trapping of analyte molecules in hot spots

X. Miao, L. Yan, et al.

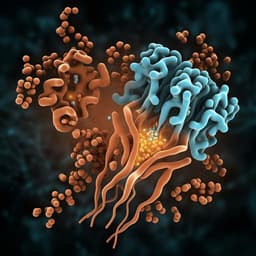

Infrared absorption spectroscopy is a powerful tool for label-free identification of molecules through their vibrational fingerprints and is widely used in scientific research and industrial applications such as biomolecular analysis¹,², process monitoring³⁴, and pollutant detection⁵⁶. Nevertheless, molecular vibrational absorption is intrinsically weak owing to its orders-of-magnitude smaller dipole moment than that of infrared wavelengths; hence, a large number of molecules are needed to achieve detectable absorption of incident infrared light. An effective approach to overcome this limitation is exploiting the strong optical near-fields of nanophotonic structures to significantly enhance molecular absorption, which is proportional to the field intensity experienced by the molecules⁷⁸. The recent development of a wide range of nanophotonic structures and devices constitutes a suitable platform for developing molecular sensors based on surface-enhanced infrared absorption (SEIRA) spectroscopy. A variety of photonic structures have been employed for SEIRA sensing, such as nano-rods⁹¹⁰, split-ring resonators¹¹, colloidal nano-particles¹²⁻¹⁵, and metal-insulator-metal type structures¹⁶⁻¹⁸. To enhance sensitivity, structures with nanometric gaps for achieving ultrahigh field confinement and enhancement were demonstrated¹⁷,¹⁹⁻²². For example, sensors based on individual bowtie antennas with a sub-3 nm gap were able to resolve vibrational signals from a few hundred molecules in the gaps⁹. Regardless of specific photonic structure designs, regions of highly enhanced near-field intensity, also referred to as hot spots, only occupy a small fraction of the total surface area of a photonic structure. Surface-enhanced molecular absorption is only significant in these hot spots. In general, higher field enhancement is typically associated with smaller hot spots.

To conduct SEIRA sensing, the analyte is usually coated over the entire sensor surface using methods such as the self-assembly of molecular layers9,11,23, spin coating20,24, DNA/protein immobilization, or the physical adsorption of biomolecules21,25. A common drawback of these convenient methods is that analyte molecules are distributed across the entire sensor surface. Therefore, only a small percentage of all analyte molecules are delivered to the sensor hot spots that produce an enhanced molecular vibrational absorption signal, whereas the majority of the analyte molecules are outside of the hot spots and do not contribute significantly to the overall sensing signal. This issue can be a major limiting factor for the sensitivity performance of SEIRA sensors as well as optical sensors in general but has not been adequately addressed in most sensor designs. Enhancing the near-field intensity is an important design strategy that has been constantly improved by employing structures with ever-smaller hot spots; however, this approach does not necessarily lead to overall sensitivity improvement alone, as reducing the sizes of hot spots typically results in a smaller amount of analyte molecules delivered to the hot spots. Therefore, developing effective approaches for targeted and efficient delivery of analyte molecules to hot spots is perhaps an equally important aspect for optimizing optical sensor performance. One of the explored approaches is to build micro- and nano-fluidic structures, such as nano-pores26 or nano-gaps27,28, to guide analyte solutions to hot spots. Although, in principle, this approach can ensure that all analyte molecules pass through the hot spots, as the molecules are still distributed in the solution and there is no concentrating mechanism, at any moment, the number of molecules in the hot spots is determined by the solution concentration. Active trapping mechanisms such as dielectrophoresis29,30, optical trapping31-33, and micro-bubble trapping34 are promising ways to concentrate and deliver nano-objects and large biomolecules (e.g., proteins and DNA). However, these trapping mechanisms require external energy sources such as a laser or an applied voltage and are not suitable for relatively small molecules. Super-hydrophobic artificial surfaces consisting of arrays of micro-pillars have been employed for passively confining large biomolecules in diluted solutions to nanophotonic structures, which led to impressive sensitivity performance35,36. However, this approach has not achieved targeted delivery of analyte molecules only to the hot spots of nanophotonic structures.

Here, we present a nanophotonic sensor design that employs hot spot structures that can passively retain and concentrate an analyte solution as it evaporates and eventually traps precipitated analyte molecules inside the hot spots, significantly enhancing its SEIRA sensitivity. We demonstrated this passive trapping functionality using several molecular species (L-proline, D-glucose, and sodium chloride) as well as nano-particles (liposomes). These SEIRA sensors reliably produce clear spectral responses to the molecular vibrational absorption associated with picogram-level analyte precipitates.

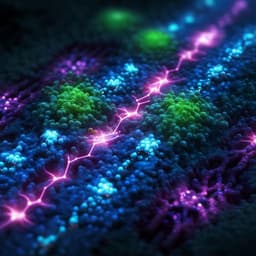

Device design: The sensors use a metal-insulator-metal (MIM) resonator structure consisting of a periodic array of Al ribbons on top of Ge ribbons with an Au back reflector. The Ge ribbons are narrower than the Al ribbons by hundreds of nanometers, forming nano-trenches on both sides of each Ge ribbon. The resonance mode is excited by incident light polarized perpendicular to the Al ribbons. The resonance frequency is tuned to target molecular absorption lines by adjusting the Al ribbon width (w), nano-trench width (L), and Ge ribbon height (d).

Field enhancement and sensing principle: Simulations show electric fields are strongly confined inside the nano-trenches, with peak electric field enhancement exceeding 40 (intensity enhancement >10^3). Molecules in the nano-trenches experience these enhanced fields, producing pronounced spectral features (Fano-like line shapes) in reflection when molecular vibrational lines overlap the resonator mode.

Passive trapping mechanism: A droplet of analyte solution is pipetted onto the sensor. The solution infiltrates the nano-trenches and, as it evaporates, the surface recedes and forms a concave meniscus between neighboring Al ribbons pinned at their edges. Upon further evaporation, the concave film ruptures, retaining solution within the nano-trenches where it concentrates; as drying completes, analyte precipitates remain inside and near the edges of the nano-trenches (i.e., the hot spots).

Numerical simulations (FDTD): Using FDTD, the effects of w and L on optical response and sensing performance were studied with d fixed at 200 nm. Reflection spectra were computed for designs with w from 800 nm to 1.4 µm at fixed L = 200 nm, and with L from 0 to 300 nm at fixed w = 1 µm, covering molecular vibrational bands broadly. L-proline was chosen as a model analyte with absorption lines between 1400 and 1700 cm⁻¹. Simulations compared reflection before and after adding 100 nm wide proline regions within the nano-trenches (inner side adjacent to Ge sidewall vs outer side). Designs with wider trenches yielded stronger spectral responses; for the same added proline amount, placement on the outer side produced larger signals than on the inner side. Electric field maps at 1453 and 1630 cm⁻¹ showed higher overall enhancement for wider trenches and consistently higher fields at the outer trench side.

Fabrication: The process uses a single lithography step and one dry etch, similar to standard MIM structures. Steps include Ge deposition on a silicon wafer, lithography and lift-off to define metal features, and plasma RIE etching of Ge to form the undercut and nano-trenches beneath the Al ribbons, with an Au back reflector layer. Fabricated resonator arrays are 300 µm × 300 µm. SEM top-views reveal Al ribbon edges, darker nano-trench stripes, and brighter Ge ribbons; FIB cross-sections confirm successful trench formation.

Experimental analyte trapping test: Aqueous solutions were prepared: L-proline (1 mg/mL), D-glucose (1 mg/mL), and sodium chloride (table salt, 40 µg/mL). Approximately 1 µL droplets were deposited on the device and allowed to dry under ambient conditions, leading to precipitation. Concentrations were chosen such that precipitate would fill most trenches. Optical microscopy showed accumulation of precipitate near Al ribbon edges, with spaces between ribbons largely clean, consistent with trapping in and near nano-trenches. A drying video (Supplementary Information) visually captured meniscus rupture and solution retention within trenches.

- Passive evaporation-driven trapping concentrates analyte within resonator nano-trenches (hot spots), overcoming the common limitation of uniform coating methods that dilute molecules over non-enhanced regions.

- Simulated peak electric field enhancement inside nano-trenches exceeds 40 (intensity enhancement > 1000×), with fields concentrated more strongly on the outer trench sides than inner sides.

- Designs with wider nano-trenches produce stronger SEIRA spectral responses; for the same amount of analyte, placement on the outer trench side yields larger differential reflection than on the inner side.

- Sensors exhibit clear Fano-like reflection features when the resonator mode overlaps molecular vibrational lines; tuning w and L aligns resonance with target absorption bands (e.g., proline lines at ~1453 and ~1630 cm⁻¹).

- Experimentally, precipitated analyte accumulates predominantly at Al ribbon edges and within trenches after drying, consistent with the proposed trapping mechanism.

- Sensitivity: Sensors generate a reflection change of a few percentage points in response to picogram-level precipitates of proline or glucose—significantly less mass than a monolayer over the same area.

The work addresses a key bottleneck in SEIRA and related optical sensing: delivering analyte molecules to the nanoscopic hot spots where field enhancements are highest. By engineering nano-trenches that both localize optical fields and passively retain and concentrate solution during evaporation, the devices trap precipitates directly within hot spots. This targeted localization increases the fraction of analyte experiencing enhanced fields, boosting spectral signals without requiring active trapping, external energy inputs, or complex microfluidics. Simulations corroborate that widening trenches increases field enhancement and that the outer trench side experiences stronger fields, explaining observed trends in spectral response. Aligning resonator frequency with specific molecular vibrational modes further maximizes sensitivity and yields characteristic Fano-like spectral signatures. The approach generalizes to various analytes and potentially to nanoparticles, offering a simple, robust route to higher sensitivity in label-free IR sensing.

The paper introduces a nanophotonic SEIRA sensor that integrates passive analyte trapping within resonant hot spots using nano-trench geometries in a metal-insulator-metal structure. The evaporation-driven mechanism concentrates analyte in the trenches, and simulations and experiments show substantial field enhancements and clear spectral responses. The sensors achieve few-percent reflection changes for picogram-level analyte masses, well below a monolayer equivalent over the device area. The fabrication is straightforward (single lithography and dry etch), and the concept is broadly applicable, potentially extending to nanoparticle sensing such as exosomes, viruses, and quantum dots. Future work may optimize trench geometry for specific targets, expand to other low-loss dielectrics, and quantify detection limits and selectivity across diverse analytes.

Related Publications

Explore these studies to deepen your understanding of the subject.