Chemistry

Electro-reduction of carbon dioxide at low over-potential at a metal-organic framework decorated cathode

X. Kang, L. Li, et al.

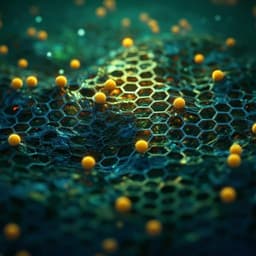

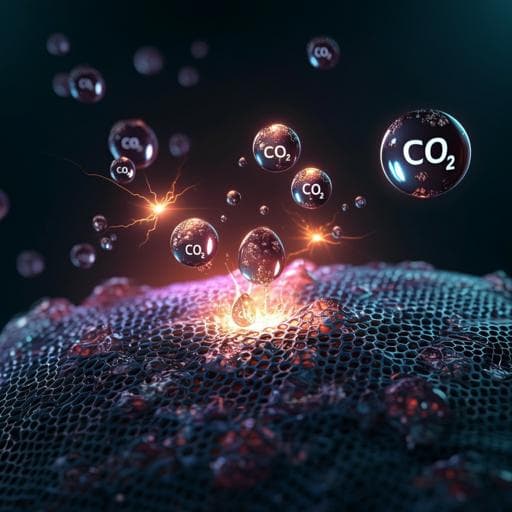

Rising atmospheric CO₂ levels drive efforts in carbon capture, storage, and conversion technologies. Electrochemical CO₂ reduction is promising due to mild operating conditions but is challenged by the high stability of the CO₂ molecule and the large overpotentials required to activate it. Copper-based electrodes can reduce CO₂ to diverse products (CO, formic acid, C₂+ products). Formic acid is an important C₁ product used industrially and as a fuel cell feed. Mechanistically, CO₂ electroreduction on Cu can proceed via O-bound HCOO⁻ or C-bound −COOH intermediates; the O-bound pathway can enhance selectivity toward formic acid. However, achieving high selectivity at low overpotentials is difficult, and high negative potentials can reduce and degrade Cu-based catalysts. Metal–organic frameworks (MOFs) offer high surface areas and tunable structures for catalysis, but highly crystalline MOFs often have low charge-transfer ability and fully coordinated, less accessible metal sites. Introducing accessible metal sites and enhancing charge transfer in MOFs are key to efficient electrocatalysis. This study investigates an ionic-liquid-templated, electrosynthesized Cu-MOF coating on Cu foam designed to introduce Cu(II) defect sites to lower onset potential and enhance selectivity for CO₂-to-formic-acid conversion.

Prior work shows Cu electrodes can produce CO, formate/formic acid, and multi-carbon products from CO₂, with selectivity influenced by intermediates (O-bound HCOO⁻ vs C-bound −COOH). Formic acid is valuable for industrial applications and fuel cells. Emerging catalysts have achieved reduced overpotentials for formate formation, including Cu-porphyrin MOFs. MOFs are attractive for gas adsorption and catalysis owing to high surface area and tunable structures, and have been explored for H₂/O₂ electrocatalysis and CO₂ reduction. However, many crystalline MOFs possess fully coordinated metal centers and poor charge transport, limiting their electrocatalytic activity. Defect engineering, incorporation of accessible metal sites, and improved electrical contact with conductive supports have been proposed to overcome these limitations. The HKUST-1 benchmark system and other Cu-MOFs highlight the role of morphology and conductivity in performance, but stability and competitive hydrogen evolution remain challenges. This work builds on templated electrosynthesis to integrate mesopores and defects, aiming to enhance CO₂ activation and selectivity toward formic acid at low overpotentials.

Synthesis and electrode fabrication: The tetracarboxylic ligand H₄L was synthesized via a three-step literature method. The defect-rich MOF film Cu₂(L)-e was grown directly on Cu foam (0.5×1.0 cm²) by electrosynthesis using a two-electrode setup (Cu foam as both electrodes) in DMF/dioxane/H₂O (2:1:1 v/v/v) with 5 drops of HCl (37%) and EmimOAc (1.0 mL) as supporting electrolyte at 60 °C under 8.0 V for 10 min. After synthesis, the electrode was solvent-exchanged with acetone/acetonitrile (1:1 v/v). A solvothermally synthesized reference MOF, Cu₂(L)-t, was prepared from Cu(NO₃)₂·3H₂O and H₂L in DMF with HNO₃ at 80 °C for 48 h. HKUST-1-e/Cu was prepared analogously using trimesic acid.

Characterization: SEM (Quanta 650) assessed morphology; PXRD (Rigaku D/MAX2500, Cu-Kα) confirmed structure; FTIR (ATR) and TGA (N₂) probed bonding and stability; N₂ sorption (77 K) and CO₂ sorption (273–298 K) measured porosity and adsorption; CFM using furfuryl alcohol oligomerization probed Lewis-acid defect sites. EPR (X- and Q-band Bruker) quantified uncoupled Cu(II) defects and binuclear paddlewheel units via spectral simulation and Boltzmann-weighted integrals. XPS/Auger characterized Cu oxidation states post-electrolysis.

Electrochemical testing: CO₂ reduction was performed in an H-type cell using 0.5 M EmimBF₄ in acetonitrile (catholyte) and 0.1 M H₂SO₄ (anolyte), separated by Nafion-115. Working electrodes: Cu₂(L)-e/Cu and HKUST-1-e/Cu used directly; Cu₂(L)-t/CP prepared by drop-casting a Nafion-bonded ink onto carbon paper. Ag/Ag⁺ (0.01 M AgNO₃ in 0.1 M TBAP-MeCN) served as reference, carbon paper as counter electrode. CO₂ was bubbled (20 mL min⁻¹, then 10 mL min⁻¹ after saturation). LSV: −1.2 to −2.4 V vs Ag/Ag⁺ at 20 mV s⁻¹. Electrolysis durations typically 2 h at selected potentials. Products: H₂ quantified by GC; formic acid by ¹H NMR. Faradaic efficiency calculated from product amount, electron number (2 e⁻ for H₂ and HCOOH), Faraday constant, and charge passed. EIS (open circuit, 5 mV, 10⁻²–10⁵ Hz) provided charge-transfer resistance (Rct). Double-layer capacitance (Cdl) and electrochemically active surface area were estimated from scan-rate-dependent capacitive currents. Time-resolved in situ EPR spectra were recorded every 15 min during electrolysis at −1.8 V to track uncoupled Cu(II) evolution.

Computations: Spin-polarized DFT (VASP, PAW, PBE-GGA, 400 eV cutoff, Γ-point sampling) modeled pristine and defect Cu₂(L) paddlewheel clusters (defect generated by cleaving one Cu–O(carboxylate) bond to create a vacant Cu(II) site). Geometry optimizations used energy/force thresholds of 10⁻⁴ eV and 0.01 eV Å⁻¹. Free-energy changes were computed using the computational hydrogen electrode, including zero-point and entropic corrections. Solvation effects were included via an implicit Poisson–Boltzmann model (Vaspsol, ε = 37.5). Competing pathways via O-bound HCOO and C-bound COOH intermediates and H₂ evolution were analyzed.

- Ionic-liquid-templated electrosynthesis produced Cu₂(L)-e as ∼50 nm nanoparticles uniformly coating Cu foam, contrasting with micron-sized octahedra from solvothermal synthesis.

- Defect quantification: Q-band EPR simulations indicate uncoupled Cu(II) defect sites are ∼15.3% in Cu₂(L)-e versus 1.5% in Cu₂(L)-t, an order of magnitude increase.

- Porosity: Cu₂(L)-e shows mixed micro/mesoporosity with total pore volume 1.89 cm³ g⁻¹ (vs 0.32 cm³ g⁻¹ for Cu₂(L)-t). CO₂ uptake at 1 bar, 298 K: 44.7 cm³ g⁻¹ for Cu₂(L)-e vs 38.5 cm³ g⁻¹ for Cu₂(L)-t; higher isosteric heat for Cu₂(L)-e indicates stronger CO₂ interactions.

- CO₂ electroreduction performance (0.5 M EmimBF₄/MeCN): Cu₂(L)-e/Cu exhibits an onset potential of −1.45 V vs Ag/Ag⁺ for formic acid formation, among the lowest in organic electrolytes. FE to HCOOH (FEHCOOH) peaks at 90.5% at −1.8 V with current density 65.8 mA cm⁻²; FEHCOOH remains >80% from −1.75 to −1.95 V. Only H₂ is detected as a byproduct across tested potentials.

- Comparisons: Cu₂(L)-t/CP onset −1.7 V, max FEHCOOH 77% at −1.9 V; HKUST-1-e/Cu onset −1.75 V, max FEHCOOH 62% at −2.05 V. Bare Cu foam at −1.8 V yields 4.2 mA cm⁻² with FEHCOOH 20.5%.

- Stability and morphology: After electrolysis, HKUST-1-e partially peeled and became amorphous; Cu₂(L)-e/Cu largely retained morphology with minor aggregation.

- Time-resolved EPR during electrolysis (−1.8 V): Uncoupled Cu(II) content increases initially, peaking at 75 min (Cu₂(L)-e/Cu), 60 min (Cu₂(L)-t/CP), and 45 min (HKUST-1-e/Cu), then decreases due to reduction to Cu(I), as confirmed by XPS/Auger. Current density for HCOOH production remains stable up to 5 h after reaching peak defect concentration.

- Charge transfer and active area: Rct values from EIS at OCP: ∼17 Ω (Cu₂(L)-e/Cu), 114 Ω (Cu₂(L)-t/CP), 408 Ω (HKUST-1-e/Cu). Cdl: 10.71 mF cm⁻² (Cu₂(L)-e/Cu), 5.31 mF cm⁻² (Cu₂(L)-t/CP), 0.55 mF cm⁻² (HKUST-1-e/Cu), indicating highest electrochemically active surface area for Cu₂(L)-e/Cu.

- DFT mechanism: On both pristine and defect models, the O-bound HCOO pathway is thermodynamically more favorable than C-bound COOH/CO formation; defects lower the free-energy barrier further, enabling selective formic acid formation and facilitating product desorption via weaker hydrogen bonding. Defect models also protonate more readily, consistent with increased H₂ evolution at very negative potentials.

The study demonstrates that introducing a high density of accessible, uncoupled Cu(II) defect sites within a thin, nanoparticulate MOF coating on a conductive Cu foam dramatically enhances CO₂ reduction to formic acid at low overpotentials. The electrosynthesized Cu₂(L)-e/Cu combines favorable morphology (nanoparticles forming a conformal, thin, porous film) with improved electronic coupling to the current collector, yielding low charge-transfer resistance and high electrochemically active surface area. EPR quantification links the abundance and temporal evolution of uncoupled Cu(II) defect sites to catalytic activity, with peak performance coinciding with maximum defect concentration. DFT supports an O-bound HCOO intermediate as the most favorable pathway, especially at defect Cu(II) sites, rationalizing the high selectivity for formic acid at moderate negative potentials. Competing H₂ evolution becomes significant at potentials more negative than −2.0 V, aligning with calculations indicating facile protonation at defect sites. Compared to solvothermal MOF coatings and HKUST-1, the templated electrosynthesis strategy yields superior onset potential, Faradaic efficiency, current density, and mechanical integrity during electrolysis. Overall, structural defects within the MOF and optimized electrode architecture synergistically address activation barriers and selectivity challenges in CO₂ electroreduction.

An integrated Cu₂(L)-e/Cu electrode was prepared by controllable electrosynthesis of MOF nanoparticles onto Cu foam, generating abundant uncoupled Cu(II) defect sites and a highly conductive, stable coating. This electrode achieves a low onset potential (−1.45 V vs Ag/Ag⁺) and high selectivity for formic acid (FEHCOOH up to 90.5% at −1.80 V) with high current density (65.8 mA cm⁻²). EPR and DFT establish that defect Cu(II) sites drive the O-bound HCOO pathway and favor CO₂ reduction over H₂ evolution at modest overpotentials. The facile MOF electrosynthesis approach provides a blueprint for designing efficient, low-overpotential CO₂ reduction electrocatalysts. Future work could focus on enhancing aqueous stability, integrating membranes or flow systems, tuning defect densities and ligand environments to further lower overpotentials, and extending the approach to other MOF chemistries and product selectivities.

- Electrolyte and stability: The Cu₂(L)-e/Cu electrode, like many Cu(II) MOFs, is unstable in water, restricting operation to nonaqueous/ionic liquid media (EmimBF₄/MeCN).

- Early electrode evolution: During the first hour of electrolysis, total Faradaic efficiency (HCOOH + H₂) is <100%, indicating ongoing electrode restructuring and transient, unaccounted processes.

- Competing reactions at high overpotentials: At potentials more negative than −2.0 V vs Ag/Ag⁺, H₂ evolution increases, reducing selectivity for formic acid.

- Structural changes over time: Time-resolved EPR/XPS show reduction of Cu(II) to Cu(I) over extended operation, potentially impacting long-term stability and activity.

- Benchmark comparison: HKUST-1-e/Cu exhibited mechanical instability (peeling, amorphization) under operation; while Cu₂(L)-e/Cu was more robust, some particle aggregation was observed post-reaction.

- System-specific conditions: Reported performance is under specific organic electrolyte, gas flow, and cell configuration; generalizability to other media or industrially relevant conditions remains to be tested.

Related Publications

Explore these studies to deepen your understanding of the subject.