Engineering and Technology

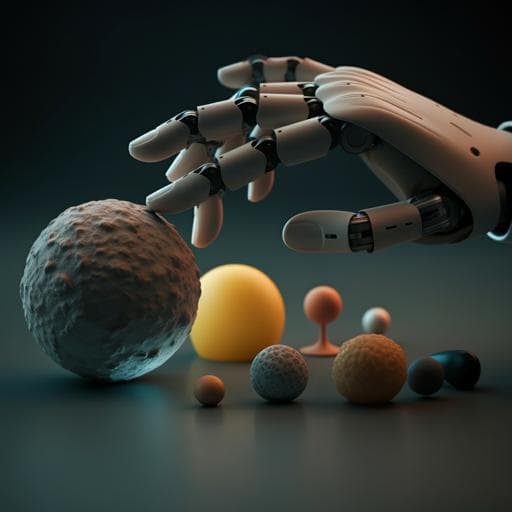

Deep learning-assisted object recognition with hybrid triboelectric-capacitive tactile sensor

Y. Xie, H. Cheng, et al.

Explore the groundbreaking development of a hybrid tactile sensor that fuses triboelectric and capacitive sensing technologies, offering unparalleled object recognition capabilities. Achieving a remarkable 98.46% accuracy through deep learning, this innovation promises to enhance robotic perception and tactile intelligence. This research was conducted by Yating Xie, Hongyu Cheng, Chaocheng Yuan, Limin Zheng, Zhengchun Peng, and Bo Meng.

Related Publications

Explore these studies to deepen your understanding of the subject.