Engineering and Technology

Conductive and elastic bottlebrush elastomers for ultrasoft electronics

P. Xu, S. Wang, et al.

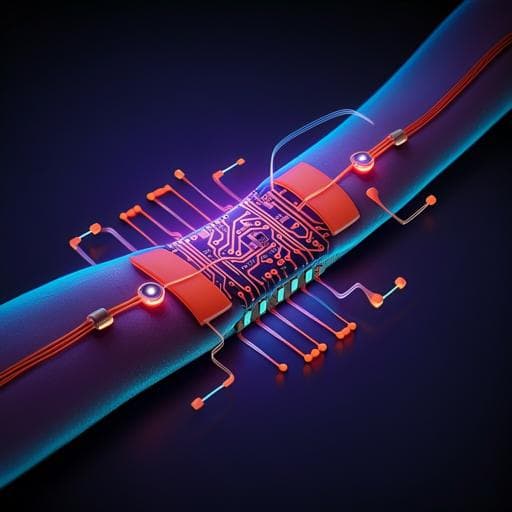

The study addresses the need for electronics that mechanically match soft biological tissues (Young’s modulus from ~10 Pa to 1 MPa) to improve biointerface performance and durability. Conventional rigid inorganic electronics (E ~1–200 GPa) and even many flexible/stretchable designs create mechanical mismatch, leading to tissue damage and device failure. Existing intrinsically stretchable materials such as hydrogels and ionogels offer softness but rely on solvents (water or ionic liquids) that limit long-term stability and environmental robustness. Ultrathin polymer sheets and nanomeshes improve conformability but require complex fabrication. Bottlebrush elastomers (BBEs), particularly PDMS-based BBEs, can achieve ultra-low moduli (<1 kPa) without solvents due to their entanglement-free architectures while retaining PDMS biocompatibility and chemical resistance; however, most BBEs are non-conductive, limiting their use in electronics. A straightforward approach is to render BBEs conductive by adding conductive fillers (e.g., carbon nanotubes, metallic nanowires), but filler toxicity, polarity mismatch, and processing complexity must be considered. Prior work demonstrated CNT-filled bottlebrush systems with E ~66 kPa and conductivity ~0.01 S/m, which remain stiffer than soft tissue and have low conductivity, and required multi-step synthesis. The purpose of this work is to create a solvent-free, ultrasoft, and conductive PDMS BBE using commercially available components and simple processing, achieve tissue-matched moduli with useful conductivity, and demonstrate integration into ultrasoft electronic devices via laser cutting and 3D printing for applications in soft robotics, wearable sensing, and electrophysiology.

The paper reviews strategies for soft and stretchable electronics, including architectural designs (serpentine and mesh layouts) that permit strain accommodation yet retain relatively high modulus, potentially causing immunological responses. Hydrogels and ionogels provide softness but contain water/ionic liquids that can diffuse and are environmentally limited. Ultrathin polymer films and nanomeshes reduce mechanical constraints but involve complex fabrication. PDMS-based bottlebrush elastomers are highlighted for achieving very low Young’s modulus (<1 kPa) without solvents due to reduced entanglement; however, their non-conductive nature limits use in electronics. A prior CNT–bottlebrush composite achieved E ~66 kPa and conductivity ~0.01 S/m via more complex synthesis, indicating room to reduce modulus to tissue-matched levels and increase conductivity. The review motivates a need for a solvent-free, ultrasoft, and conductive elastomer with straightforward preparation and integrable fabrication methods.

Materials: Commercially available methacrylate-functionalized PDMS monomer (MCR-M11, Mn ~1000 g/mol) and crosslinker (DMS-R22, Mn ~10,000 g/mol) from Gelest were purified through basic alumina columns. Thermal initiator AIBN (2 mol% relative to total PDMS monomers and crosslinkers) was used. SWCNTs (≥80%, TUBALL) served as conductive fillers. Fumed silica (AEROSIL R711) was used as a thixotropic agent for non-conductive printing inks. Preparation of pure PDMS BBEs: MCR-M11, DMS-R22, and AIBN (2 mol%) were mixed (vortex 3000 rpm, 10 min). Crosslinking ratios (monomer:crosslinker, MM:CL) were 600:1, 900:1, or 1200:1 to tune network strand length. Precursors were cast in Teflon molds and thermally cured at 80 °C under N2 overnight to form solvent-free BBEs. Preparation of conductive SWCNT/PDMS BBEs: Using the softest matrix (MM:CL = 1200:1), SWCNTs were added at 0.2, 0.4, or 0.6 wt% to the BBE precursors and mixed in a custom ball miller for 30 min with intermittent cooling (4 °C after every 4 min). Mixtures were degassed under vacuum overnight and cured at 80 °C under N2 overnight to form percolating SWCNT networks in the bottlebrush matrix. Mechanical testing: Cyclic uniaxial tensile tests (ISO 37-Type 4 dumbbell; narrow portion 2 mm × 12 mm) were performed on a custom tensile tester (0.2 N load cell) at traverse speeds 25, 50, and 100 mm/min (strain rates 0.035, 0.070, 0.14 s⁻¹). Samples underwent 20 cycles or up to 1000 cycles at maximum strains of 50%, 100%, 200%, or 400%. Young’s modulus for pure BBEs was obtained via an unentangled network fitting model; for SWCNT/BBEs, E was from linear fits of 0–10% strain. Lap-shear adhesion tests (dry) were performed with elastomers and porcine skin backed by rigid tape and cyanoacrylate; adhesion area 13.8 mm × 10 mm; shear strength was maximum force divided by area. Electrical and electrochemical characterization: Resistance of SWCNT/BBEs (37.6 mm × 13.8 mm × 2 mm) was measured with a source meter (Keithley 2614B), using a Ag flakes–EGaIn composite at contacts to reduce contact resistance. Conductivity σ = l/(R·A) with l = 37.6 mm and A = 27.6 mm². Electrochemical impedance spectroscopy (Autolab PGSTAT302N) spanned 10 Hz to 0.1 Hz, 10 mV AC, no DC bias. On-skin impedance used 8 mm diameter, 2 mm thick circular electrodes of SWCNT/BBE (0.2, 0.4, 0.6 wt%), hydrogel, and copper film; electrode spacing 1 mm; Ag–EGaIn composite used at probe interfaces. Environmental stability: SWCNT/BBE (0.4 wt%) samples were stored in ambient air (23 °C), HCl solution (pH 2, room temperature), or H2O2 (30 wt%, 4 °C). Resistance was measured after 10, 20, and 30 days (solution-stored samples dried at 60 °C for 1 h before measurement). Cytotoxicity: Human dermal fibroblasts cultured on pure BBE and SWCNT/BBE (0.2, 0.4, 0.6 wt%). After 24 h, viability assessed by MTS assay; absorbance at 490 nm; normalized to blank control. Rheology and 3D printing inks: Rheology (DHR-3, 40 mm plates, 1 mm gap, 25 °C). For conductive inks, SWCNTs (0.2–0.6 wt%) provided thixotropy and shear thinning; 0.4 and 0.6 wt% enabled rapid shear recovery and print fidelity, while 0.2 wt% was insufficient. For insulating inks, fumed silica at 4.5 wt% (selected over 6.5 wt% to retain softness) imparted shear thinning and recovery with low modulus (~3.89 kPa). Direct-ink-writing (Engine SR, Hyrel 3D) used 5 cc syringes and 0.58 mm nozzles; prints cured at 80 °C under vacuum overnight. Patterning and device fabrication: Laser cutting produced single-layer conductor geometries (resolution ~0.6 mm) in SWCNT/BBE (0.4 wt%), followed by encapsulation with pure BBE to form covalently integrated structures via interpenetrating networks across the interface. 3D co-printing enabled multilayer devices using conductive SWCNT/BBE (0.4 wt% for sensors; 0.6 wt% for electrodes) and insulating silica/BBE (4.5 wt%). Electrical connections were made with Ag–EGaIn composite and sealed with Ecoflex as needed. Demonstrations: (1) Laser-cut strain sensor adhered (via intrinsic adhesion) to Ecoflex pneumatic actuators and to human skin (knuckle/fingertip); compared against SWCNT/Ecoflex sensors for mechanical constraint and adhesion. (2) SWCNT/BBE sensor adhered to a hornworm to monitor motion with minimal mechanical interference. (3) 3D-printed 5×5 touch pad: orthogonal SWCNT/BBE strip layers separated by BBE spacer; top/bottom insulators of silica/BBE or spray-coated pure BBE for higher sensitivity; readout via Arduino and MATLAB GUI; calibration for force response and limit of detection. (4) 3D-printed SWCNT/BBE ECG electrodes (0.6 wt%) used in RA/LA/RL configuration; compared on-skin impedance versus copper and hydrogel electrodes; ECG signals recorded with AD8232 module and Arduino.

- Pure PDMS BBE softness and elasticity: By tuning crosslinking ratio (MM:CL = 600:1, 900:1, 1200:1), Young’s modulus spanned ~0.63–1.85 kPa; materials exhibited fully reversible deformation up to 400% strain with minimal hysteresis over 20 cycles and stable elasticity over 1000 cycles at 400% strain. Elasticity was strain-rate independent (0.035–0.14 s⁻¹).

- Adhesion of pure BBE: Lap-shear (MM:CL 1200:1) shear strengths on various substrates: Sylgard 184 0.63 kPa; Ecoflex 0.34 kPa; glass 0.73 kPa; copper 0.87 kPa; porcine skin 0.63 kPa. Adhesion attributed to van der Waals interactions and ultra-soft conformal contact.

- Conductive SWCNT/BBE properties: At 0.2, 0.4, 0.6 wt% SWCNT, Young’s moduli were 2.98, 5.29, and 10.65 kPa; conductivities were 2.68, 7.08, and 13.78 S/m, respectively. EIS showed frequency-independent impedance and ~0° phase, indicating electronic conduction. 0.4–0.6 wt% balanced softness and conductivity; >0.6 wt% increased modulus (>15 kPa) and hindered dispersion.

- Strain/pressure sensing: Normalized resistance increased with tensile strain; gauge factor decreased with higher SWCNT loading due to denser networks. Material exhibited good pressure sensitivity in 0–2 kPa due to low modulus. Durability: small drift over 2500 tensile cycles to 100% strain.

- Environmental stability: SWCNT/BBE (0.4 wt%) displayed negligible resistance changes over 30 days in air, HCl (pH 2), and H2O2 (30 wt%), outperforming commercial hydrogel electrodes which showed significant resistance increase after 4 h in ambient air.

- Adhesion of SWCNT/BBE: Higher lap-shear strengths than pure BBE on tested substrates, enabled conformal adhesion to skin and ability to lift small objects.

- Cytotoxicity: 24-h human dermal fibroblast viability: pure BBE 99%; SWCNT/BBE 0.2 wt% 77%; 0.4 wt% 79%; 0.6 wt% 64%, indicating relatively low but SWCNT-dependent cytotoxicity.

- Laser-cut strain sensor on soft robot: SWCNT/BBE sensor (0.4 wt%) imposed negligible constraint on Ecoflex pneumatic actuator bending compared to SWCNT/Ecoflex sensor which reduced bending angles. On-skin sensors adhered robustly and responded rapidly to finger bending/touch.

- Soft-bodied animal sensing: SWCNT/BBE sensor adhered to hornworm without affecting crawling speed or body length change; stable resistance signals during locomotion.

- 3D-printed touch pad (5×5): High spatial resolution (1.5 mm pitch). Force range per sensor 0–0.1 N; limit of detection 0.00029 N; capable of detecting very light objects (e.g., petal 0.11 g) and enabling e-skin-mediated human–robot interaction.

- 3D-printed ECG electrodes: On-skin impedance of 0.6 wt% SWCNT/BBE electrodes comparable to hydrogel electrodes and slightly lower than copper at <3 Hz, attributed to superior conformal contact. ECG signals (P wave, QRS complex, R wave) comparable to commercial hydrogel electrodes, demonstrating feasibility without dehydration issues.

The research establishes that a solvent-free, ultrasoft, and conductive elastomer can be realized by combining unentangled PDMS bottlebrush networks with percolating SWCNT fillers. By optimizing crosslinking (MM:CL = 1200:1) and filler loading (0.2–0.6 wt%), the composites achieve soft tissue-matched moduli (2.98–10.65 kPa) while providing practical electronic conductivity (2.68–13.78 S/m). Intrinsic adhesion and environmental stability broaden applicability for long-term, conformal biointerfaces. Patterning via laser cutting and 3D co-printing preserves ultra-softness and enables both single-layer and multilayer device architectures. Device demonstrations show minimal mechanical constraint in soft robots, stable wearable sensing on skin and soft-bodied animals, ultrasensitive touch interfaces, and wearable electrophysiology with performance comparable to hydrogel electrodes. While conductivity is lower than metallic nanomaterial conductors, the achieved balance between softness, conductivity, adhesion, and stability directly addresses the core challenge of mechanical mismatch in bioelectronics and opens pathways for ultrasoft e-skins, sensors, and electrodes.

This work introduces a simple, scalable route to solvent-free, ultrasoft, and conductive PDMS bottlebrush elastomers using commercially available monomers, crosslinkers, and SWCNT fillers. The materials deliver tissue-matched Young’s moduli (2.98–10.65 kPa), useful conductivities (2.68–13.78 S/m), inherent adhesion, and strong environmental stability. Two compatible patterning routes—laser cutting and 3D co-printing—enable fully BBE-based devices including strain sensors, high-sensitivity touch pads, and wearable ECG electrodes that function comparably to hydrogel-based standards while avoiding dehydration. Future work could pursue higher conductivity without compromising softness (e.g., optimizing SWCNT dispersion, alternative conductive fillers or hybrid networks), comprehensive biocompatibility assessments (including identifying/removing potential impurities in commercial SWCNTs), long-term in vivo studies, and expanded device architectures for multimodal sensing and actuation.

- Conductivity–softness trade-off: Increasing SWCNT loading beyond 0.6 wt% raises modulus (>15 kPa) and complicates dispersion; conductivity remains below metallic conductor composites.

- Cytotoxicity considerations: Reduced fibroblast viability at higher SWCNT loadings (64% at 0.6 wt%) suggests potential biocompatibility concerns, possibly due to impurities in commercial SWCNTs; requires further purification/assessment.

- Adhesion strength: Although intrinsically adhesive, lap-shear strengths are modest (<1 kPa), lower than conventional adhesives (>10 kPa), which may limit use under high shear or wet conditions without additional fixation.

- Printing additives: Adding fumed silica to enable insulating ink printability increases modulus and hysteresis, requiring trade-offs between print fidelity and ultra-softness.

- Frequency-dependent performance and contact resistance: While EIS indicates electronic conduction, absolute conductivity and electrode–skin contact quality can vary with surface preparation; Ag–EGaIn interfaces were used to minimize contact resistance, which may not be practical in all applications.

- Generalizability: Device demonstrations were benchtop-scale; long-term in vivo performance and large-area manufacturing reliability were not assessed.

Related Publications

Explore these studies to deepen your understanding of the subject.