Chemistry

Chemically resistant and thermally stable quantum dots prepared by shell encapsulation with cross-linkable block copolymer ligands

J. Ko, B. G. Jeong, et al.

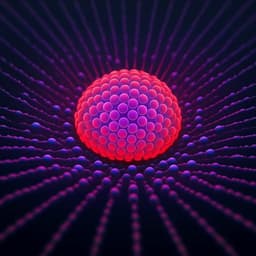

A myriad of academic research and industrial applications related to semiconductor nanocrystals, also referred to as quantum dots (QDs), has been conducted to take advantage of their outstanding color purity and unique size-dependent color-tunability due to the "quantum confinement effect"1-3. In addition to the above characteristics of QDs, their superb photoluminescence quantum yield (PLQY) and wide tunability over the entire visible range allow QDs to be potential key materials for displays4-9, bioimaging10,11, photodetectors12,13, and photovoltaic cells14. Despite these advantages, QDs are extremely vulnerable to external stimuli such as heat15-17, oxidation18-20, and moisture21, as it is well known that these factors create charge trap sites on the surface of QDs. For this reason, industrial and practical applications of QDs involving baking or drying processes that cause irreversible thermal and oxidation damage to QDs have been limited.

However, the most effective way to overcome the instabilities of QDs against external harsh environments is the passivation of emissive QDs with chemically robust, thick inorganic shells9,22-24. However, such core/shell heterostructuring encounters inherent limitations; building a thick shell beyond the critical thickness results in the creation of misfit defects near the core/shell interface that bring about a decrease in the PLQY of QDs25,26. The growth of thin oxide inorganic materials, such as SiO222,27-29 or Al2O330, was also devised to protect QDs from oxidation, but the growth of these shell materials is often accompanied by unexpected oxidation of QDs that yields irreversible degradation of QDs31-33.

Stabilizing QDs with ligands that strongly bind onto the QD surface has attracted tremendous attention as an alternative chemical means to endow QDs with photo-chemical or thermal stability34-37. Despite the decent progress made with thiolated ligands, the thermal dissociation of the ligands due to the relatively weak binding energy between ligands and inorganic surfaces38 has limited the use of ligand protective layers in application fields where QDs are exposed to heat. Recently, the cross-linked network formation of ligands was used to structurally inhibit the detachment of ligands from the surface of metal nanoparticles39-42, but this approach has not been directly applicable to QDs because it involves rather harsh chemical reaction conditions for cross-linking of ligands that could deteriorate the photophysical properties of QDs.

Here, we demonstrate a novel means for imparting QDs with a high thermochemical stability by successfully introducing a cross-linked block copolymer as a network ligand to QDs. Our method is based on the formation of a physical barrier on QDs, which effectively suppresses the generation of surface defects. To do this, thiol-terminated block copolymer ligands with poly(methyl methacrylate) (PMMA) and poly(glycidyl methacrylate) (PGMA), P(MMA-b-GMA)-SH, were carefully designed to passivate QDs. The resulting QDs are covered by a PMMA outer shell, providing high miscibility in typical optical PMMA film, and a PGMA inner shell, having epoxy groups that accomplish the cross-linking reaction via a cationic ring-opening polymerization under ambient conditions without damaging the QDs43. Since no external energies (UV or heat) are applied during the cross-linking reaction, no negative effect on the photophysical properties of QDs was observed after encapsulation of the QDs. The resulting QDs are encapsulated with cross-linked polymeric protective layers that effectively passivate the QD surfaces. This passivation not only reduces the probability of surface oxidation but also prevents QD-thiol bonds from dissociating under harsh environmental conditions such as high temperature (either in solution or nano-composite film states). Furthermore, we demonstrated white light-emitting diodes (WLEDs) by stacking red and green QD-PMMA nanocomposite films on blue-emitting LED chips with an easy processability and cost-effective method.

Materials: Reagents included toluene, THF, MIBK, methanol, n-hexane, MMA, GMA, CPBD, AIBN, hexylamine, tris(pentafluorophenyl)borane, PMMA homopolymer (Mn = 60,000 g/mol, PDI = 1.11), and various QD precursors (In(acet)3, PA, ODE, Zn(acet)2, OA, TOP, Se, S, TOA, CdO, DDT, ZnCl2, MA, (TMS)3P). All were used as received.

Precursor preparation: Stock solutions prepared and stored under Ar: 0.5 M Cd(OA)2 in ODE; 0.5 M Zn(OA)2 in ODE; 0.5 M In(PA)3; 2 M Se in TOP (TOPSe); 2 M S in TOP (TOPS).

Synthesis of CdSe/ZnCdS core/shell QDs: CdO (128 mg, 1 mmol), MA (685 mg, 3 mmol), and ODE (15 mL) were heated to 240 °C to form Cd(MA)2. After transparency, TOPSe (5 mmol, 0.25 mL) was swiftly injected to form CdSe cores (radius ≈ 2 nm; yield ≈ 56%). After 3 min at 270 °C, Zn(OA)2 (3 mL of 0.5 M, 1.5 mmol) and DDT (202 mg, 1 mmol) were sequentially injected to grow a ~0.5 nm Cd0.6Zn0.4S inner shell (30 min). Then Cd(OA)2 (1 mmol, 2 mL), Zn(OA)2 (2 mmol, 4 mL), and TOPS (3 mmol, 1.5 mL) were separately added within 1 min to form a ~3 nm Cd0.5Zn0.5S outer shell (10 min). Products were purified by precipitation/redispersion and dispersed in toluene (yield ≈ 59%).

Synthesis of InP/ZnSeS core/shell QDs: In(PA)3 (0.5 mmol, 1 mL) in ODE (10 mL) was degassed at 110 °C, then heated to 270 °C under Ar. A mixture of (TMS)3P (62 mg, 0.25 mmol) and TOP (2.5 mmol, 1.25 mL) was rapidly injected to nucleate. After 20 min, the reaction was cooled; cores purified by acetone precipitation/toluene redispersion and stored in toluene (100 mg/mL) at 4 °C (yield ≈ 45%). For shelling, Zn(OA)2 (0.75 mmol, 1.5 mL) in ODE (10 mL) was heated to 110 °C (vacuum/Ar), then InP QDs (0.1 mL) were added and heated to 300 °C. TOPSe was injected to grow ZnSe shell (30 min), followed by additions of Zn(OA)2 and TOPS to grow ZnS shell (1 h at 310 °C). Purified twice and dispersed in toluene (yield ≈ 52%).

Synthesis of P(MMA-b-GMA)-SH via RAFT: Step 1: PMMA macro-CTA prepared by RAFT polymerization of MMA (5 g, 49.94 mmol) with CPBD (0.096 g, 0.43 mmol) and AIBN (0.071 g, 0.043 mmol) at 75 °C for 24 h under Ar; precipitated in cold methanol to yield PMMA-RAFT (Mn = 9,300 g/mol; PDI = 1.23). Step 2: Chain extension with GMA (1.6 g, 11.26 mmol) using PMMA-RAFT (3 g, 0.32 mmol) and AIBN (0.0053 g, 0.032 mmol) at 70 °C for 6 h; precipitated to yield P(MMA-b-GMA)-RAFT (Mn = 12,100 g/mol; PDI = 1.21). Step 3: End-group transformation to thiol by nucleophilic substitution with hexylamine (4 eq) in anhydrous THF; stirred overnight until color change (pink to pale yellow); precipitated and dried to obtain P(MMA-b-GMA)-SH as white powder.

Ligand exchange: Single-phase exchange in toluene: QDs (10 mg in 2 mL) mixed with P(MMA-b-GMA)-SH (40 mg in 3 mL). Reacted 48 h, then precipitated with cold n-hexane. Redispersed in toluene; precipitation/redispersion repeated 3 times to remove unbound species (final dispersion 1 mg/mL in MIBK).

Encapsulation via PGMA cross-linking: Polymer-grafted QDs in MIBK were treated with tris(pentafluorophenyl)borane (B(C6F5)3) at 4 equivalents to total PGMA epoxy groups to initiate cationic ring-opening polymerization under ambient conditions for 24 h. Products were precipitated with n-hexane and redispersed in toluene (≈5 mg/mL).

QD–PMMA nanocomposite films: Glass substrates were solvent-cleaned (acetone, methanol, isopropyl alcohol; sonication 15 min each). Composite solutions: QDs 0.5 wt% and PMMA (Mn = 60,000 g/mol) 1 wt% in toluene; films formed by spin casting at 4000 rpm. Free-standing films prepared by BOE float and transfer for TEM; cross-sections (~100 nm) by FIB.

White QD-LED fabrication: In 1 g of 15 wt% PMMA in chloroform, red CdSe/ZnCdS (5 mg) and green InP/ZnSeS (20 mg) P(MMA-b-GMA)-QDs were dispersed by sonication to clarity. The viscous solution was cast in a 2 cm diameter, 0.7 mm deep Al dish, dried overnight, then freestanding film was laminated onto a blue InGaN LED chip.

Characterization: Polymer ligands analyzed by GPC (THF eluent; calibrated with PS standards) and NMR. DLS (BI-200SM, 616 nm laser) determined QD hydrodynamic diameters (toluene, RT). Optical absorption (Jasco V-670) and PL (Horiba Fluoromax-4). PLQY determined relative to CdS/CdSe/CdS SQWs (radius 5.1 nm, absolute PLQY 90%) at OD = 0.1, λex = 450 nm; absolute PLQY of SQWs measured with QE-2100 integrating sphere system. TEM at 200 kV (Tecnai 20) for morphology. Time-resolved PL by TCSPC (520 nm pulsed excitation; monochromator + PMT; IRF ~0.2 ns). EL metrics (EL spectra, CRI, CCT, CIE) by diode array analyzer with integrating sphere.

- Cross-linkable P(MMA-b-GMA)-SH ligands (Mn ≈ 9.3 kg/mol PMMA; 2.8 kg/mol PGMA) were synthesized and successfully grafted to QDs, forming a double shell (PGMA inner, PMMA outer).

- Ligand exchange significantly increased hydrodynamic diameters, indicating successful polymer grafting: CdSe/ZnCdS QDs from 13.5 nm to 27.1 nm; InP/ZnSeS QDs from 7.8 nm to 21.0 nm (DLS).

- High grafting densities achieved after exchange (from TGA): ~1.30 chains/nm² (CdSe-based) and ~1.18 chains/nm² (InP-based), sufficient for interchain PGMA contacts and cross-linking outside the mushroom regime.

- Residual oleic acid after exchange: ~3 wt% (≈57 mol%), corresponding to chain densities of 1.84 chains/nm² (CdSe) and 1.53 chains/nm² (InP), aiding surface passivation alongside polymer ligands.

- Estimated unperturbed Rg: PMMA block ≈ 2.8 nm; PGMA block ≈ 1.3 nm, supporting brush regime at ρ ≈ 1 chain/nm².

- Mild cationic ring-opening cross-linking of PGMA with B(C6F5)3 under ambient conditions preserved optical properties: absorption/emission spectra essentially unchanged post-exchange and post-cross-linking; only a slight PLQY decrease (~5%) during ligand exchange.

- Conventional UV/photoacid cross-linking caused significant PL quenching irrespective of QD type, underscoring the advantage of the Lewis acid method.

- Encapsulated QDs exhibited exceptional tolerance to heat and oxidants in both solution and PMMA nanocomposite films under various harsh conditions (as stated), maintaining photophysical integrity.

- Demonstrated facile fabrication of WLEDs by stacking red and green QD–PMMA composite films on blue InGaN LED chips, indicating device-relevant robustness and processability.

The study addresses the longstanding problem of QD degradation under heat and oxidative environments by forming a polymeric double-shell barrier around QDs. A high-density "grafting-to" approach with thiol-terminated P(MMA-b-GMA) provides dense surface coverage that, after cationic ring-opening cross-linking of PGMA, yields a robust inner network in intimate contact with the QD surface. This network suppresses the creation of surface trap states and inhibits ligand desorption at elevated temperatures, while the PMMA outer brush ensures optical transparency and compatibility with polymer matrices. Optical measurements confirm that the gentle Lewis-acid-initiated cross-linking preserves the QDs’ absorption/emission characteristics and PLQY, unlike UV/photoacid approaches that quench PL. The increased hydrodynamic diameters, high grafting densities, and residual OA corroborate effective surface passivation. Collectively, these features translate to enhanced thermochemical stability in solution and in PMMA nanocomposites, enabling practical processing (spin-coating, casting) and device integration (e.g., WLEDs) without compromising QD photophysics.

This work introduces a simple, effective encapsulation strategy for QDs using thiol-terminated P(MMA-b-GMA) block copolymer ligands that form a PMMA outer brush and a cross-linked PGMA inner shell via mild Lewis acid catalysis. The approach maintains QD photophysical properties while dramatically improving resistance to heat and oxidation in both solution and polymer-film environments. The method is broadly applicable to different QD chemistries (CdSe/ZnCdS and InP/ZnSeS) and facilitates straightforward fabrication of robust QD–polymer composites and WLEDs. Future work could optimize ligand architecture (block lengths, compositions), explore alternative cross-linkable chemistries and catalysts for broader solvent/process compatibility, and quantify long-term operational stability in device-relevant stress tests (thermal cycling, high-flux illumination, humidity) and across diverse polymer matrices.

Related Publications

Explore these studies to deepen your understanding of the subject.