Chemistry

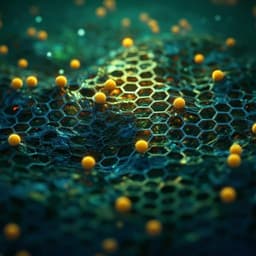

Boosting membrane carbon capture via multifaceted polyphenol-mediated soldering

B. Zhu, S. He, et al.

This innovative paper by Bin Zhu, Shanshan He, Yan Yang, Songwei Li, Cher Hon Lau, Shaomin Liu, and Lu Shao presents a cutting-edge molecular soldering strategy utilizing multifunctional polyphenols to significantly enhance mixed-matrix membranes for carbon capture. This breakthrough approaches the long-standing permeability-selectivity trade-off, ensuring exceptional CO2 separation performance in various polymers.

Playback language: English

Related Publications

Explore these studies to deepen your understanding of the subject.