Chemistry

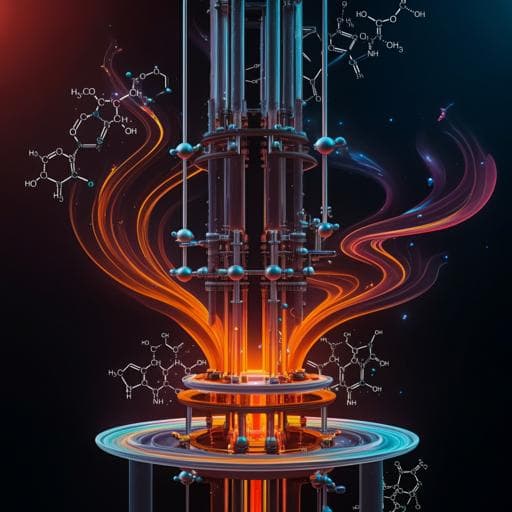

Bayesian optimization-driven parallel-screening of multiple parameters for the flow synthesis of biaryl compounds

M. Kondo, H. D. P. Wathsala, et al.

Discover how Masaru Kondo and colleagues revolutionized the synthesis of biaryl compounds using a flow system and a Brønsted acid catalyst. Their innovative approach, enhanced by Bayesian optimization, achieved impressive yields and streamlined the process, paving the way for efficient gram-scale production.

Related Publications

Explore these studies to deepen your understanding of the subject.