Engineering and Technology

Antifouling graphene oxide membranes for oil-water separation via hydrophobic chain engineering

C. Yang, M. Long, et al.

Massive oily wastewater is produced from petrochemical, machining, textile, and food industries, with produced water estimated at ~250 million barrels per day. Discharge regulations (<40 mg/L oil) drive the need for advanced treatment. Membrane technology is promising for emulsified oil-water separation due to high efficiency and low energy use, but fouling by spreadable oil droplets severely degrades performance, especially at high flux where concentration polarization increases oil-membrane interactions. Graphene oxide (GO) membranes offer high flux, yet mitigating fouling at high flux remains a key challenge. Amphiphilic surfaces that combine hydrophilic and hydrophobic domains can provide fouling-resistance (via hydration barriers) and fouling-release (via low surface energy), but introducing hydrophobic domains often diminishes surface hydration and worsens resistance. Precise molecular-scale surface chemistry is needed to minimize interfacial interactions while maintaining hydration. The authors aim to construct an amphiphilic GO membrane and regulate interfacial interactions by hydrophobic chain length to achieve ultralow fouling at high flux.

Amphiphilic antifouling surfaces that incorporate fluorinated hydrophobic domains onto hydrophilic substrates have proven effective in medical devices, marine antifouling, and membrane separation. Hydrophilic domains induce hydration layer barriers that resist spreading, while hydrophobic domains facilitate pollutant release through low surface energy. However, balancing fouling-resistance and fouling-release is difficult because nonpolar hydrophobic domains tend to reduce surface hydration and promote spreading. Prior work regulated amphiphilicity by adjusting hydrophobicity, content, and distribution of hydrophobic domains. Few studies have optimized interfacial interactions by directly modulating hydration of amphiphilic surfaces, and the molecular-level effects of hydrophobic domain chain length on hydration capacity remain unclear. Coordination-driven metal-bridging assembly has emerged for constructing hydrophilic phytic acid (PA) coatings and fluorinated domains on membranes.

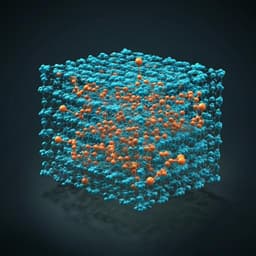

Membrane fabrication: Hydrophilic GO (hGO) membrane was prepared by assembling Fe3+-phytic acid (PA) complexes onto GO nanosheets via coordination. A dispersion containing 0.50 mg GO and 49.50 mg PA in 25 mL water was shaken (150 rpm, 25 °C, 10 min). Then 5 mL of 0.20 mM FeCl3 solution was added and shaken for 10 min to form Fe3+-PA@GO nanosheets. A 1800 µL aliquot was dispersed in 100 mL water and filtered onto polyacrylonitrile (PAN) supports to form hGO membranes. Amphiphilic F-hGO membranes were obtained by sequentially immersing hGO in FeCl3 (30 mL, 0.60 mM, 10 min, 100 rpm, 25 °C) followed by ethanol solutions of perfluorocarboxylic acids (2.00 mM, 10 min) and rinsing. Chain-length variants used: HFBA (C4), PFHA (C6), PFOA (C8), NFDA (C10), denoted F4-hGO, F6-hGO, F8-hGO, F10-hGO. The density of perfluoroalkyl chains was tuned by FeCl3 concentrations (0.20–0.80 mM). Characterization: FTIR and XPS confirmed functionalization; F/P ratios from XPS assessed fluorine content; TEM-EDS mapping verified even distribution. Wetting and interfacial measurements: Water contact angles (WCA), apparent surface energy (γsv and components), underwater oil contact angles (UOCA) with hexadecane, and normalized contact area were measured. UOCA dependence on γsv was compared to theoretical predictions using Young’s equation for solid–liquid–liquid and Wenzel’s equation; roughness factor r from AFM. Underwater oil adhesion forces were quantified by AFM using hexadecane droplets as probes. Additional UOCA tests with tetrachloromethane and n-hexane assessed universality. Hydration analysis: Differential scanning calorimetry (DSC) of ~10 mg water on membrane surfaces measured crystallization temperature and enthalpy to infer interfacial water amount. Molecular dynamics (MD) simulations: Simple model substrates (random atoms, density 0.005 nm−3; total charge Q = −10 e) with 12 anchored perfluorocarboxylic acid chains on a hexagonal lattice (carboxyl C fixed at z = 0.5 nm) were constructed for C4, C6, C8, C10. Systems contained 1000 SPC/E water molecules; Na+ added for neutrality. Water molecule rigidity enforced via SHAKE. Nonbonded interactions: Lennard-Jones with 1.0 nm cut-and-shift; electrostatics with 1.0 nm cutoff and PPPM long-range correction (accuracy 10−5). LAMMPS used with periodic boundaries; velocity-Verlet timestep 1 fs; Nosé–Hoover thermostat (τ = 100 fs) at 300 K; substrates and carboxyl C atoms frozen. Simulations ran 2 ns equilibration + 10 ns production. Analyses included water density profiles perpendicular to surfaces, hydration layer water amount, and orientation distributions of interfacial water (cos α, α angle between opposite water dipole and surface normal), separated into two regions within the hydration layer. Oil–water separation testing: Hexadecane-in-water emulsion (average droplet size 291.1 nm) used to evaluate rejection, permeance, flux decline ratio (DRr), and flux recovery ratio (FRR). Performance under varying initial fluxes (including ~310 L m−2 h−1), cycling stability, gypsum scaling (6 h), and different oil-in-water emulsions were assessed. Performance metrics: Rejection (>98%), filtrate oil concentration (<20 ppm), permeance (~620 L m−2 h−1 bar−1), DRr, FRR.

- Sequential assembly of hydrophilic PA and hydrophobic perfluorocarboxylic acids on GO produces amphiphilic membranes with continuous hydrophilic and discrete hydrophobic domains. Fluorine content increases with chain length (C4→C10) at similar coordination densities, confirmed by XPS F/P ratios and EDS mapping.

- Wetting: Water contact angle increases monotonically with perfluoroalkyl chain length; apparent surface energy γsv (especially dispersion component γsd) decreases accordingly. Despite lower γsv, all membranes remain underwater superoleophobic to hexadecane. Underwater oil contact angle (UOCA) shows a nonmonotonic, inverted-U dependence on chain length, peaking at C6: F6-hGO UOCA = 165.7°, with the smallest normalized contact area among variants.

- Theory vs experiment: Experimental UOCAs exceed values predicted by Young’s and Wenzel’s equations due to surface hydration effects. Notably, F6-hGO exhibits higher UOCA than F4-hGO at lower γsv, indicating hydration modulation dominates.

- Adhesion: AFM underwater oil adhesion force is minimized at C6. Representative values: F4-hGO 1.01 µN; F6-hGO 0.54 µN (~50% reduction vs C4); F10-hGO 1.20 µN. For F10-hGO relative to F6-hGO, γsv decreases by ~15% but contact area increases by >60%, yielding higher adhesion.

- MD simulations: Interfacial water density profiles show an interfacial layer with density > bulk; its peak sharpness first decreases then increases with chain length. Hydration layer water amount rises then falls with chain length, maximized at C6, indicating strongest hydration capacity at medium chain length. Water orientation distributions in two hydration regions are most similar (more uniform) at C6, providing more interaction sites and stronger hydration. DSC corroborates interfacial water amount order: F6-hGO > F8-hGO > F4-hGO.

- Separation performance: For hexadecane-in-water emulsion (avg 291.1 nm), all membranes achieve high rejection (>98%) at high permeance (~620 L m−2 h−1 bar−1); filtrate oil <20 ppm. Optimized amphiphilic surface (C6; FeCl3 0.6 mM) attains DRr = 6.8% and FRR = 99.8%, dramatically improved over GO (DRr 60.0%, FRR 73.3%) and hGO (DRr 31.8%, FRR 88.6%). F6-hGO maintains ultralow DRr at relatively high initial flux (~310 L m−2 h−1), outperforming state-of-the-art GO-based and polymeric membranes. The membrane shows stable cycling (pure water flux comparable to initial after multiple foul/clean cycles), minimal flux decline under gypsum scaling (6 h), and broad applicability to various emulsions (rejection >98%, DRr <10%).

- Generality: Nonmonotonic hydration and UOCA behavior with chain length also observed using other oils (tetrachloromethane, n-hexane), indicating universality of chain-length-controlled hydration effects.

The study addresses the persistent challenge of oil fouling in high-flux membrane separation by engineering amphiphilic GO surfaces at the molecular scale. By tuning the perfluoroalkyl chain length, the authors modulate both surface energy and, critically, the hydration structure. While lower surface energy typically promotes oil spreading, the results reveal a nonmonotonic dependence of hydration capacity on chain length, with C6 chains maximizing interfacial water amount and uniformity of orientation. This enhanced hydration strengthens steric and energetic barriers to oil spreading, enabling simultaneous optimization of fouling-resistance (small contact area) and fouling-release (low interfacial adhesion). Consequently, F6-hGO exhibits the highest underwater superoleophobicity, the lowest oil adhesion, and superior antifouling metrics at high permeance and initial flux compared with benchmark membranes. The deviation of experimental UOCA from classical models underscores the decisive role of interfacial hydration beyond surface energy considerations. The findings provide mechanistic insight into how nanoscale surface chemistry dictates macroscopic antifouling performance and suggest a general design principle for amphiphilic interfaces in separation and related interfacial technologies.

An amphiphilic GO membrane was created via sequential assembly of hydrophilic phytic acid and hydrophobic perfluorocarboxylic acids. Hydrophobic chain engineering revealed that perfluoroalkyl chain length governs interfacial hydration and, thereby, interfacial interactions with oil. Medium-length chains (C6) induce the most uniform interfacial water orientation and highest hydration capacity, yielding minimal oil adhesion and contact area. The optimized membrane achieves ultralow fouling (DRr ~6.8%, FRR ~99.8%) at high permeance (~620 L m−2 h−1 bar−1) with high oil rejection (>98%) and robustness under cycling and scaling challenges. This molecular-level understanding offers a design framework for balancing fouling-resistance and fouling-release in membranes and potentially benefits interfacial engineering in oil recovery, biomedicine, and nanofluidics. Future work could expand chain-chemistry and topology explorations (e.g., branched or mixed-length domains), assess long-term stability and environmental considerations, and generalize the approach to diverse membrane materials and complex oily wastewaters.

Related Publications

Explore these studies to deepen your understanding of the subject.