Engineering and Technology

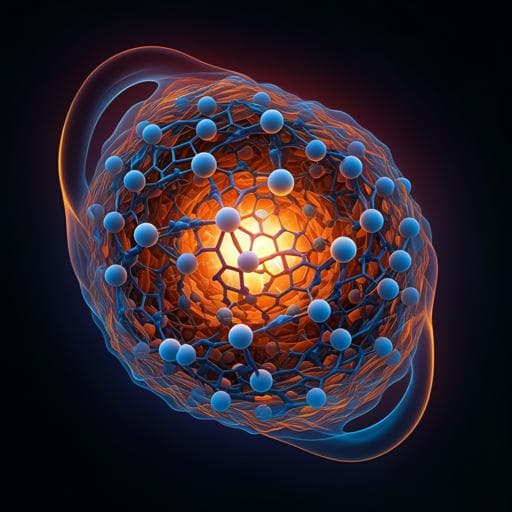

An order-disorder core-shell strategy for enhanced work-hardening capability and ductility in nanostructured alloys

F. Duan, Q. Li, et al.

This groundbreaking research by Fenghui Duan and colleagues presents a novel core-shell nanostructure that overcomes the limitations of nanocrystalline metallic materials. Achieving an impressive tensile strength of 2.65 GPa and a uniform elongation of 17%, this innovative design not only enhances strength but also maintains ductility and thermal stability. Don't miss out on how this could revolutionize high-performance materials!

~3 min • Beginner • English

Introduction

Nanocrystalline (NC) metals offer very high strength via grain refinement but typically exhibit poor work-hardening, leading to limited uniform elongation (<5%) and low thermal stability due to high grain boundary (GB) energy that drives coarsening. The long-standing challenge is to achieve a synergy of high strength (>2 GPa), sufficient ductility (>10%), and good thermal stability (>0.5 Tm). Prior approaches such as heterogeneous nanostructuring to generate geometrically necessary dislocations or chemical heterogeneity to promote dislocation accumulation have improved ductility but often at the expense of strength or with only modest ductility gains. Ordered superlattice materials can enhance dislocation interlocking and accumulation due to anti-phase boundary (APB) effects but are typically brittle because of weak GB cohesion. The research goal here is to design an NC architecture that simultaneously enables strong dislocation storage (for work-hardening), easy dislocation emission (to initiate plasticity), and improved GB cohesion to avoid intergranular fracture, while also stabilizing the nanostructure at elevated temperatures.

Literature Review

The work builds on decades of grain-size strengthening (Hall–Petch) studies and known limitations of NC metals in ductility and stability. Strategies including heterogeneous nanostructures and composition undulations have partially mitigated these issues, but often trade strength for ductility or yield <10% uniform elongation. Ordered superlattice materials (e.g., Ni3Al-based) are known for high APB energies that impede dislocation motion and suppress cross-slip, enhancing dislocation interaction and storage, yet they suffer from brittle GBs. Prior studies have shown that third elements (e.g., B) can alter GB cohesion in Ni3Al and that alloying (e.g., Co, Fe) can reduce ordering tendency and promote fcc disordering. Recent advances in chemically complex intermetallics and nanostructuring (nanolamellae, nanotwins, coherent nanoprecipitates) provide strength-ductility improvements, but achieving >2 GPa strength with >10–15% uniform elongation and high thermal stability in NC alloys remains challenging.

Methodology

Alloy and processing: Multi-component alloy Ni42.4Co22.4Fe9.8Al11.0Ti12.6B1.8 (at.%) ribbons were produced by single-roller melt-spinning (quench temperature ~1623 K) under Ti-gettered Ar, achieving high cooling rates (>1×10^6 K s^-1). Ribbon thicknesses 13–60 μm were obtained by varying roller speed (10–38 m s^-1) and gas pressure (0.04 MPa); cooling rate strongly depends on thickness (e.g., ~1×10^5 K s^-1 at 60 μm; ~1×10^7 K s^-1 at 15 μm). Grain size was tuned from ~204 to 79 nm via cooling rate control. A small fraction (<2%) of Ti–B-rich borides formed, with size and fraction decreasing at higher cooling rates.

Microstructural characterization: Transmission Kikuchi diffraction (TKD) mapped grain size/orientation (equiaxed nanograins; average ~98 nm). HAADF-STEM and FFT analyses identified an order–disorder core–shell architecture: ordered L12 superlattice grain interiors (OSG) enveloped by a disordered fcc interfacial nanolayer (DINL) 2–6 nm thick (avg ~3 nm). Lattice mismatch between DINL and OSG was ~0.2%. Volume fraction of DINL was estimated by f_DINL = 1 − (1 − t/d)^3 (t ~3 nm; d ~98 nm), yielding ~7.1% in NC vs ~0.13% in coarse-grained (CG) counterparts. Atomic-resolution EDS mapped sublattice occupations: (Ni,Co) on the A-sublattice, (Al,Ti) on the B-sublattice; Fe on both sublattices.

3D atom probe tomography (3D-APT): LEAP 5000 XR at 70 K (voltage mode; 200 kHz; 20% pulse; 0.3% detection). ROI cylinders (10 nm diameter) perpendicular to interfaces; 1D profiles (bin 0.3 nm). DINL showed enrichment of Fe, Co, B and depletion of Ni, Al, Ti. Peak DINL concentrations: Co ~31 at.%, Fe ~18 at.%, B ~4 at.%, roughly +8.6, +8.2, and +2.2 at.% relative to grain interiors.

Mechanical testing: In-situ SEM micro-tension at room temperature using Hysitron P185 PicoIndenter, nominal strain rate 5×10^-4 s^-1. Dog-bone micro-tensile specimens with rectangular cross-sections ~1.3 μm × 1.5 μm and gauge lengths 2–3 μm (100–250 grains across section) were FIB-fabricated. Larger cross-sections (3×3 and 4×4 μm^2) were also tested (FemtoTools FT-NMT04) to assess size effects. Stress–strain curves were corrected using elastic modulus; video-based strain verification performed. In-situ observations recorded slip band formation and fracture morphologies.

Thermal stability: Ribbons (d ~98 nm) were sealed in Ar and annealed 1073–1273 K for 1 h. Cross-sectional nanohardness (Hysitron T1950, 8 mN, 10 s dwell) measured at least 10 indents per condition. TEM/EDS characterized grain growth, interfacial chemistry changes, and nanoprecipitates after annealing. Thermodynamic rationale (reduced GB energy via interfacial disordering and high-entropy GBs) and kinetic pinning (DINL composition contrast and Ti–B nanoprecipitates) were evaluated.

Models/estimates: APB energy estimated via composition-dependent model (Crudden et al.), indicating ~296 mJ m^-2 for the L12 OSG (more than double Ni3Al ~110 mJ m^-2). Ordering strengthening Δσ_os ~900 MPa. Hall–Petch coefficient k_HP ~510 MPa μm^1/2 from CG–NC data; Δσ_HP ~1.8 GPa at d = 79 nm. Lattice mismatch δ = 2(a_OSG − a_DINL)/(a_OSG + a_DINL).

Key Findings

- Architecture: A robust order–disorder core–shell nanostructure was realized in NiCoFeAlTiB: L12-ordered superlattice grain interiors encapsulated by a coherent disordered fcc interfacial nanolayer (DINL) of ~3 nm average thickness, lattice mismatch ~0.2%, and ~7.1 vol% in NC samples.

- Chemistry at interfaces: 3D-APT showed DINL enrichment of Co (~31 at.%), Fe (~18 at.%), and B (~4 at.%) with respective increases of ~8.6, ~8.2, and ~2.2 at.% vs interiors; Ni, Al, Ti were depleted. Co/Fe cosegregation promotes local disordering of the interface.

- Mechanical performance (room temperature):

• CG reference (d ~11 μm): σy ~1.04 GPa, σu ~1.6 GPa, εu ~25%.

• NC core–shell d = 124 nm: σy ~1.97 GPa, σu ~2.45 GPa, εu ~(15 ± 1.0)%, elongation to failure ~34%.

• NC core–shell d = 98 nm: σy ~2.20 GPa, σu ~2.65 GPa, εu ~(17 ± 1.8)%, elongation to failure ~31%.

• Micro-tension size effect negligible: σu ~2.58–2.61 GPa and εu ~14–15% for 3×3 and 4×4 μm^2 cross-sections.

• Control without interfacial disordering (d = 79 nm): very high σy ~2.97 GPa but fractured with near-zero plasticity, underscoring the necessity of DINL for ductility.

- Work-hardening behavior: Unlike conventional NC fcc alloys that rapidly lose work-hardening after ~5% strain, the core–shell samples exhibit elevated work-hardening rates with a plateau at intermediate strains, indicating sustained dislocation accumulation.

- Strengthening contributions: High APB energy (~296 mJ m^-2) leads to strong ordering strengthening Δσ_os ~900 MPa. Hall–Petch coefficient k_HP ~510 MPa μm^1/2 (higher than disordered multicomponent and pure Ni-based alloys), yielding Δσ_HP ~1.8 GPa at d = 79 nm. Precipitation strengthening from Ti–B-rich borides is minor: ~165 MPa (d = 124 nm) and ~18 MPa (d = 98 nm).

- Deformation mechanisms: DINL acts as a dislocation source and accommodates intergranular strain; OSG’s high APB energy suppresses cross-slip, promoting superdislocation interlocking and storage inside grains. TEM/HAADF revealed high dislocation densities (~10^15 m^-3) in nanograins, multidirectional slip bands, and dimpled fracture, indicating ductile failure without intergranular cracking.

- Thermal stability: Onset grain coarsening temperature Ton ~1173 K (nanohardness ~9.0 GPa at RT, ~8.3 GPa at 1173 K). Grain size increased from ~98 nm (as-spun) to ~355 nm after 1173 K/1 h; extensive grain growth and hardness drop occurred only beyond 1173 K. Ton exceeds that of conventional NC superlattices (e.g., Ni3(Si,Ti)) and most NC HEAs and even nanotwinned Ni alloys.

- Stabilization mechanisms: Thermodynamic—lower GB energy via interfacial disordering and high-entropy GB complexions; Kinetic—GB pinning by compositionally distinct DINL requiring collective diffusion and by Ti–B nanoprecipitates (Zener pinning).

Discussion

The order–disorder core–shell architecture directly addresses the strength–ductility–stability trade-off in NC metals. The disordered fcc DINL along GBs reduces the barrier for dislocation nucleation and transmission, enhances GB cohesion, and mitigates intergranular fracture, enabling early and sustained plasticity. Simultaneously, the ordered L12 grain interiors, with high APB energy, impede dislocation motion and suppress cross-slip, fostering superdislocation interlocking and storage that sustains work-hardening to high strains and prevents strain localization. This cooperative mechanism yields exceptional uniform elongation (15–17%) at ultrahigh strengths (~2.5–2.65 GPa) and avoids the softening typical of NC fcc metals. The architecture also improves thermal stability: interfacial disordering reduces GB energy (lower driving force for coarsening) and high-entropy GB effects further decrease GB energy, especially at elevated temperatures. Kinetically, GB migration is hindered by the compositionally distinct DINL (requiring collective multi-element diffusion) and by Ti–B-rich nanoprecipitates that exert Zener pinning. Compared to NC ordered superlattices without interfacial disordering, which show brittle intergranular failure, the presence of DINL is decisive for ductility. Overall, the design unifies high base strength (ordering + Hall–Petch) with enhanced work-hardening and superior coarsening resistance.

Conclusion

This work demonstrates a general strategy to achieve simultaneous ultrahigh strength (>2 GPa), large uniform ductility (>15%), and high thermal stability (Ton ~1173 K) in nanostructured alloys by introducing an order–disorder core–shell architecture. A thin, coherent, disordered fcc interfacial nanolayer promotes dislocation emission and plastic compatibility at GBs, while ordered L12 superlattice grain interiors with high APB energy promote dislocation interlocking and storage, delivering sustained work-hardening. The multi-component, high-entropy character of the interfacial layer also stabilizes the nanostructure thermally via reduced GB energy and kinetic pinning. This design philosophy could be extended to other chemically complex intermetallic systems and nanostructured alloys by tailoring interface chemistry and ordering to balance dislocation source activity and storage. Future work may explore scaling to bulk components, cyclic/fatigue performance, and optimizing interfacial chemistry/thickness across broader alloy chemistries and processing windows.

Limitations

Most mechanical tests were conducted on micro-tension specimens fabricated from melt-spun ribbons, with bulk-scale validation inferred via minimal size effects but not directly demonstrated. The beneficial DINL formation depends on processing (cooling rate); at the highest cooling rates (d ~79 nm), interfacial disordering was suppressed, resulting in near-zero plasticity despite very high strength, indicating a processing window sensitivity. The study focuses on a single alloy family/composition; broader generalization to other systems and service conditions (e.g., fatigue, environment) remains to be established.

Related Publications

Explore these studies to deepen your understanding of the subject.