Chemistry

Activating low-temperature diesel oxidation by single-atom Pt on TiO2 nanowire array

S. Hoang, Y. Guo, et al.

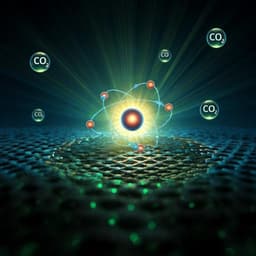

Discover the groundbreaking research by Son Hoang and colleagues on a single-atom platinum catalyst that achieves an impressive 90% conversion of CO and hydrocarbons at a chilling -160 °C. This remarkable catalyst showcases durability under harsh conditions while using significantly less precious metal, paving the way for more efficient diesel exhaust catalysis.

~3 min • Beginner • English

Introduction

Low-temperature oxidation of CO, hydrocarbons (HCs), and NOx is critical for ultra-clean, energy-efficient emission control in mobile and stationary systems (e.g., DOCs, TWCs, SCR, LNT). Many low-temperature catalysts (Au, Co3O4, mixed oxides, perovskites) suffer from poor hydrothermal stability and sulfur poisoning. Supported PGM single-atom catalysts (SACs) offer high dispersion and selectivity but face stability challenges due to atom mobility and aggregation, and most demonstrations have been limited to model reactions (CO oxidation, WGS) and lab-scale powders. The research question is whether durable, practical Pt single-atom catalysts can be realized on robust supports and integrated into field-size monoliths to deliver superior low-temperature diesel oxidation performance under realistic exhaust conditions. The study aims to anchor single-atom Pt on rutile TiO2 nanowire arrays grown directly on cordierite honeycombs and evaluate activity, durability (hydrothermal and sulfur tolerance), and mechanism under simulated and transient diesel exhaust.

Literature Review

Prior studies showed promising low-temperature oxidation using Au and various metal oxides, but with limited hydrothermal stability and sulfur tolerance. SACs of PGMs have demonstrated high reactivity/selectivity owing to high dispersion and strong metal-support interactions, yet isolated atoms tend to sinter under synthesis/reaction conditions, limiting durability. Pt SACs on CeO2 prepared via atom trapping achieved excellent CO oxidation (full conversion ~148 °C) and stability to ~500 °C but deactivated at 800 °C. Success for low-temperature hydrocarbon oxidation using supported SACs has been scarce, and evaluations have been largely confined to lab-scale reactors rather than field-size monoliths under realistic exhaust protocols. These gaps motivate exploration of robust supports and architectures to stabilize single Pt atoms and translate SAC benefits to practical DOC applications.

Methodology

- Support synthesis: Vertically aligned mesoporous rutile TiO2 nanowire arrays (NAs) were grown in situ on cordierite honeycomb channels via a nonpolar solvent/hydrophilic substrate interfacial reaction under hydrothermal/solvothermal conditions. Reagents included a nonpolar solvent, Ti(IV) alkoxide precursor, TiCl4 (1 M in toluene), and concentrated HCl. Cl− directs anisotropic rutile (110) growth. Post-growth sonication (acetone, ethanol, water) removed organics and Cl residues. Resulting NAs (~3 μm height) consist of bundled nanowires (10–20 nm) with mesoporosity; a thin mesoporous SiO2 layer forms from cordierite leaching during acidic growth.

- Pt loading: (i) Microwave-assisted dip-coating: repeated dip, blow-dry, microwave dry (1–3 min) cycles from diluted Pt precursor (0.5 mg mL−1), followed by calcination at 500 °C (2–4 h; additional 1 h at 700–900 °C for porosity studies). (ii) Na-promoted wet incipient impregnation (WII): Pt precursor (50 μg mL−1) with NaOH (Na/Pt=10), aged 12 h at 80 °C, evaporated at 50 °C with periodic rotation, dried 150 °C (12 h), calcined 500 °C (4 h). Volumetric Pt loadings: 0.53–1.73 g L−1 (0.18–0.58 wt.%).

- Aging and durability: Hydrothermal aging (HT) 700 °C for 100 h in 12% O2, 6% CO2, 6% H2O/N2 for probe/simulated exhaust tests; transient engine test samples aged 650 °C for 100 h in 10% H2O/air. Mechanical adhesion assessed by ultrasonication (40 kHz, 4 h) weight loss.

- Characterization: SEM, TEM/HRTEM, HAADF STEM (ac-HAADF to visualize single Pt atoms), XRD (rutile phase), BET/BJH (surface area/pore size), N2 isotherms, H2 chemisorption (Pt dispersion), H2-TPR (redox behavior), XPS (Pt oxidation state), in situ XAS (Pt L3-edge XANES/EXAFS under CO oxidation), in situ DRIFTS (CO adsorption/oxidation). DFT (VASP, PBE, D3 dispersion) on rutile TiO2(110) surfaces with/without Ti vacancies; NEB for transition states; assessed Pt binding energies and CO oxidation mechanisms.

- Catalytic testing (bench/protocol): Continuous flow and customized plug-flow reactors. USDRIVE ACEC protocols for simulated diesel exhaust: CDC and LTC-D compositions with GHSV 60,000 h−1; degreening at 550 °C (CDC) or 700 °C (LTC-D) for 4 h; temperature ramp 100→500 °C at 2 °C min−1; products by FTIR. Probe reactions cycles (30,000 h−1) varying CO/C2H4/C3H6/C3H8. S-poisoning per USDRIVE: 5 ppm SO2 in full simulated exhaust at 300 °C, 30,000 h−1 for 5 h (≈1 g S L−1 exposure); performance measured pre-/post-sulfation and after desulfation (700 °C, 3% H2/1% CO/N2 30 min; recalcine 500 °C 2 h).

- Transient engine-relevant testing: Full-size monolith (5 cm × 7.5 cm; 0.53 gPt L−1) tested under highly transient feed mimicking HDD FTP on a Cummins ISB 6.7 L engine; emissions monitored (transient and cumulative HC/CO).

Key Findings

- Structure and dispersion:

- Rutile TiO2 nanowire arrays uniformly coat cordierite channels; high BET surface area (~89.6 m2 g−1; post-Pt ~45.7 m2 g−1; after HT aging ~16 m2 g−1) with array structure retained after aging.

- Pt predominantly atomically dispersed on TiO2 NW/NA surfaces. H2 chemisorption Pt dispersion: ~80% (0.71 gPt L−1) and ~74% (1.73 gPt L−1) for Na-promoted WII; dip-coating yields atomic dispersion plus some Pt NPs on adjacent SiO2 (dispersion 33% and 24%).

- In situ EXAFS/XANES: dominant Pt–O shell at 1.6 Å (R-space), fitted CN ~5.5 Pt–O at 1.99±0.02 Å; Pt oxidation state between 2+ and 4+; persists under CO/O2 at RT.

- DFT: single Pt atoms most stable at five-fold coordinated Ti vacancies (Pt–TiV), anchored by 5–6 O neighbors; binding energy 10.44–11.09 eV; coexistence of Pt4+ (6-coord) and Pt2+ (5-coord) consistent with EXAFS/XPS.

- Mechanism and reactivity:

- DRIFTS: linearly adsorbed CO on ionic Pt+ (~2085 cm−1) largely removed by O2 at RT (≈80% decrease in 10 min), fully removed at 100 °C, indicating room-temperature CO oxidation activity.

- DFT identifies favored Eley–Rideal (ER) pathway for CO oxidation with very low barrier (0.2 eV ≈ 19 kJ mol−1); experimental apparent activation energy ~22.7 kJ mol−1. LH pathways are unfavorable (~1.8 eV barrier for O2 dissociation).

- H2-TPR: reduction peaks at ~103 °C (isolated Pt) and ~508 °C (bulk TiO2); additional peak at ~186 °C indicates Pt-induced TiO2 reduction via strong metal–support interaction.

- Catalytic performance (simulated exhaust, CDC; GHSV 60,000 h−1):

- Pt1/TiO2 NA (0.71 gPt L−1) light-off T90: CO 164 °C; C2H4 172 °C; C3H6 173 °C; THC 178 °C (all <200 °C). Methane oxidation not emphasized at low T.

- Outperforms commercial DOC (4.66 gPt L−1): THC T90 improved by ~172 °C (commercial ~350 °C) despite ~5× lower PGM.

- NO oxidation: max NO→NO2 conversion 47% at 291 °C vs 27% at 427 °C for commercial DOC.

- Compared to Pt NP references: Pt NP/TiO2 NA (1.73 gPt L−1) T90 higher by ~23–45 °C (CO 193 °C; C3H6 196 °C; C2H4 196 °C; THC 223 °C). Pt NP/meso-SiO2 also inferior at same Pt loading.

- Durability and poisoning:

- Thermal robustness: no deactivation during ~36 h cycling with periodic 820 °C spikes (10 min) while operating at 330 °C; CO conversion ~100%, THC >90% maintained.

- Hydrothermal aging: single-atom Pt dispersion retained after 700 °C/100 h HT and simulated exhaust treatments (HAADF STEM); some <7 nm pore closure reduces accessible sites.

- Sulfur tolerance (LTC-D, 1.73 gPt L−1): after ~1 g S L−1 SO2 exposure, CO and unsaturated HC T90 increase ~19 °C; propane oxidation improves (likely interfacial sulfates), lowering THC T90 by ~9 °C. Post-desulfation, CO activity surpasses pre-S, and unsaturated HC activity nearly fully recovers.

- Transient HDD FTP-like testing (full-size, 0.53 gPt L−1): aged sample shows HC oxidation nearly as good as fresh; transient and cumulative HC/CO emissions low after warm-up; slight CO response delays at high flow/concentration attributed to partial pore closure limiting site access.

Discussion

Findings demonstrate that atomically dispersed Pt on rutile TiO2 nanowire arrays enables exceptional low-temperature diesel oxidation. The superior activity versus Pt nanoparticles arises from distinct electronic structures and reaction pathways of single Pt ions and strong metal–support interactions at Ti vacancies, which favor an Eley–Rideal mechanism with a very low activation barrier for CO oxidation. The hierarchically ordered mesoporous NA architecture provides efficient mass transport (macrochannels between bundles with mesoporosity within bundles), mitigating diffusion limitations even at high GHSV and helping inhibit Pt sintering. Robust anchoring of Pt at Ti vacancies ensures hydrothermal stability and sulfur tolerance, translating single-atom catalysis from model systems to field-size monoliths under realistic, transient exhaust conditions. These results address the low-temperature activity challenge in DOCs and support broader application of durable SACs on engineered nano-array supports.

Conclusion

A practical, durable single-atom Pt catalyst anchored on mesoporous rutile TiO2 nanowire arrays integrated into full-size cordierite monoliths was developed. The catalyst achieves 90% conversion of CO and hydrocarbons at temperatures as low as ~160–180 °C under simulated diesel exhaust, outperforming a commercial DOC while using ~80% less PGM. Single Pt ions stabilized at Ti vacancies (5–6 O coordination) deliver high activity via an ER mechanism and maintain dispersion after severe hydrothermal aging and sulfur exposure. The scalable solvothermal growth of TiO2 NAs combined with simple dip-coating or impregnation provides a viable route to manufacture field-ready SAC-based DOCs. Future work could optimize NA architecture for diffusion/accessibility post-aging, extend to other reactions (e.g., NO oxidation optimization, methane oxidation), explore other SAC metals/supports, and quantify site-normalized kinetics under transient conditions.

Limitations

- Partial pore closure (<7 nm) after hydrothermal aging reduces accessible Pt sites, causing slower CO response under high flow and concentration in transient tests.

- Direct turnover frequency measurements were not feasible due to steep light-off and complex flow, limiting intrinsic activity comparison.

- While enhanced reducibility suggests potential for rich/lean excursions, comprehensive evaluation under cycling rich/lean conditions remains to be conducted.

- Methane oxidation at low temperature was not demonstrated; focus was on CO, C2H4, and C3H6/THC.

Related Publications

Explore these studies to deepen your understanding of the subject.