Engineering and Technology

A stable quasi-solid electrolyte improves the safe operation of highly efficient lithium-metal pouch cells in harsh environments

Z. Chang, H. Yang, et al.

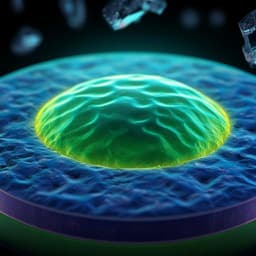

The study addresses the long-standing safety and stability challenges of lithium-metal batteries (LMBs) and high-voltage cathode systems when operated under harsh conditions such as high temperature and mechanical damage. Conventional liquid electrolytes volatilize and decompose at elevated temperatures, causing safety hazards and fast cell failure, while solid-state electrolytes suffer from brittleness and poor interfacial contact, leading to high resistance and instability. Quasi-solid electrolytes, which sit between liquid and solid states, potentially combine the advantages of both by offering mechanical stiffness, better safety (nonflammability), good interfacial contact, and higher ionic conductivity than solid-state electrolytes. The research aims to exploit sub-nanoconfinement within a polar, flexible metal-organic framework (MOF, 6.5 Å channels) to confine trace amounts of carbonate-based liquid electrolyte, thereby creating a stable, nonflammable quasi-solid electrolyte with extended electrochemical stability to enable safe, efficient, high-voltage NCM-811//Li pouch cells at temperatures up to 90 °C and even after mechanical damage.

Prior work highlights the trade-offs between liquid and solid electrolytes in LMBs: liquid electrolytes offer high ionic conductivity but are volatile and flammable, especially at high temperature, while solid electrolytes can block dendrites but often exhibit brittleness, poor electrode contact, and high interfacial resistance (refs. 24–29). Strategies such as concentrated and fluorinated electrolytes can extend stability windows and reduce flammability, yet safety and durability under harsh conditions remain difficult (refs. 6–19). Sub-nanoconfinement and coordination in porous materials have been shown to dramatically alter properties of confined molecules, mostly studied in aqueous systems (refs. 32–35). Confining small amounts of liquid electrolyte within nanoporous or sub-nanoporous hosts has emerged as a promising quasi-solid strategy to improve electrode contact, lower volatility, and enable stability at high temperatures (concept in Fig. 1b,c). This work extends those concepts to organic carbonate electrolytes within a polar MOF host, targeting high-voltage operation and safety in practical pouch cells.

Host and electrolyte design: A CuBTC MOF decorated with poly(sodium 4-styrene-sulfonate) (CuBTC-PSS, 6.5 Å channels) was used to confine trace amounts of carbonate electrolyte. The MOF exhibits polar heterogeneous internal surfaces with unsaturated Cu sites to physically confine and chemically coordinate solvent molecules. The confined electrolyte is termed a quasi-solid electrolyte. Characterization of confinement and thermal behavior: Powder XRD was used to identify electrolyte coordination within MOF channels via a reappearing (111) peak and reduced pore size (pore size distribution). Thermogravimetric analysis (TGA) compared bulk liquid electrolyte (1 M LiTFSI in propylene carbonate, 1M LiTFSI-PC) to the MOF-based quasi-solid, revealing shifts in solvent and salt decomposition temperatures. Electrolyte structure and electrochemical stability: ATR-FTIR and Raman spectroscopy probed electrolyte configuration, indicating stronger Li–PC and Li–TFSI interactions and a highly aggregated configuration in the confined electrolyte versus 1 M and even 3 M LiTFSI-PC. Linear sweep voltammetry (LSV), PITT, and CV assessed electrochemical stability windows. Ionic conductivity and activation energies were measured using symmetric cells with stainless steel electrodes. Nonflammability was assessed via ignition tests on glass fiber for liquid and within MOF for quasi-solid. Mass/Thickness benchmarking: The weights and thicknesses of a commercial solid electrolyte (LAGP), a typical liquid electrolyte system (PP separator + electrolyte), and the MOF-based quasi-solid (MOF/electrolyte film) were measured and compared. Electrode and cell fabrication: NCM-811 cathodes (8:1:1 active:carbon:PVDF) with high mass loading (~20 mg cm-2) were prepared on Al foil; coin and pouch cells (4 × 5 cm2) were assembled. Quasi-solid electrolyte films (~38 µm) containing trace liquid electrolyte (<0.23 µL cm-2, 0.3 mg cm-2) were pressed in intimate contact with electrodes and Li metal. For comparison, cells with 1 M LiTFSI-PC (70 µL in coin cells; ~25 µL cm-2 in pouch) and PP separator were assembled. Electrochemical testing: Coin and pouch cells were cycled between 2.7–4.4 V at room temperature (25 °C) and 90 °C. Additional stress tests included bending and cutting of pouch cells at 90 °C. Li//Li symmetric cells evaluated Li plating/stripping stability. LFP//Li and LTO//Li half-cells were also tested. Post-mortem and operando analyses: SEM examined cycled NCM-811 cathodes and Li anodes for morphology, CEI, and dendrites. Depth-resolved etching FT-IR and XPS mapped interphase composition and thickness. A tape-peeling method exposed internal depths of cycled NCM-811, followed by SHINERS-enhanced Raman to track electrolyte signals versus depth. XRD of cycled MOF-based electrolytes monitored the persistence of chemically coordinated electrolyte (111 peak). BET tracked consumption of physically confined electrolyte over cycling. Synthesis and materials details (Methods): CHNs were synthesized and converted to CuBTC; PSS was incorporated to obtain CuBTC-PSS. MOF films were made by mixing activated MOF (90 wt%) with PTFE (10 wt%), casting on Al, detaching in methanol, compacting (>10 tons), and activation. Electrolytes (1 M and 3 M LiTFSI-PC) were prepared. The quasi-solid electrolyte was obtained by harvesting the MOF layer with confined electrolyte from cycled Li//Li cells (10 cycles) and used as a membrane in subsequent tests.

- Sub-nanoconfinement and coordination in CuBTC-PSS channels produce a quasi-solid electrolyte with: (i) highly aggregated electrolyte configuration (stronger Li–PC and Li–TFSI interactions than 1 M and even 3 M LiTFSI-PC), (ii) extended electrochemical stability window to ~5.4 V vs Li/Li+, and (iii) nonflammability at high temperature.

- Thermal stability: Compared to bulk 1 M LiTFSI-PC where solvent decomposition starts

100 °C and salt+50 °C), attributed to physical confinement and chemical coordination to MOF sites.350 °C, the quasi-solid shifts solvent decomposition to nearly 200 °C (+100 °C) and salt decomposition to nearly 400 °C ( - Mass/thickness advantages: LAGP solid electrolyte: 185.8 mg cm-2, 560 µm; typical liquid electrolyte system: 33.9 mg cm-2 (1.5 mg cm-2 PP + 32.4 mg cm-2 electrolyte), 20 µm; MOF-based quasi-solid: 3.5 mg cm-2 total (~38 µm) with only 0.3 mg cm-2 (0.23 µL cm-2) liquid confined, highlighting potential for high energy density.

- Ionic transport: The quasi-solid shows slightly lower ionic conductivity than the liquid electrolyte but higher than LAGP, with activation energy Ea = 0.096 eV (vs. LAGP 0.160 eV), at both 25 °C and 90 °C.

- Safety: Ignition tests show the quasi-solid electrolyte is nonflammable, whereas liquid electrolyte ignites readily.

- Interphases: NCM-811 cathodes cycled in liquid developed a rough, CEI-covered surface after 50 cycles; in quasi-solid, surfaces remained smooth and essentially CEI-free even after 300 cycles. Depth-resolved etching FT-IR/XPS for liquid showed strong carboxylate (C–O, 1355 cm-1) and carbonyl (C=O, 1596 cm-1) decomposition products through ~50 nm depth, whereas quasi-solid showed mainly PVDF binder signals, indicating suppressed electrolyte decomposition at the cathode.

- Lithium metal compatibility: Li cycled with liquid showed rough, dendritic morphology; with quasi-solid, Li surfaces were smooth with minimal dendrites, indicating stabilized plating/stripping.

- Electrolyte distribution during cycling: Raman with tape-peeling showed electrolyte-related peaks at all depths within the NCM-811 cathode, indicating that physically confined electrolyte can exit MOF channels to wet the cathode. XRD retained the (111) peak after cycling, indicating chemically coordinated electrolyte remains in MOF; BET trends indicate progressive consumption of only the physically confined fraction.

- Pouch-cell performance (NCM-811 mass loading ~20 mg cm-2): Quasi-solid at 90 °C delivered 191.5 mAh g-1 initial and 171.2 mAh g-1 after 300 cycles (~89–90% retention). At 25 °C it also showed excellent stability. Under harsh tests at 90 °C after bending and cutting, capacity remained high: ~167.7 mAh g-1 (36–77 cycles, after bending) and 166.2 mAh g-1 after cutting (78–100 cycles), with ~164 mAh g-1 after 100 cycles in damaged condition.

- Comparator liquid-electrolyte pouch cells: At 25 °C, rapid decay to 19.9 mAh g-1 by 32 cycles; at 90 °C, failure after ~30 cycles with capacity sustained at 22.7 mAh g-1, and severe degradation after bending/cutting at room temperature.

The quasi-solid electrolyte leverages sub-nanoconfinement and strong coordination to polar MOF sites to create a highly aggregated solvation environment with reduced free solvent molecules and more compact Li+ solvation sheaths. This configuration raises oxidation onset, widens the electrochemical stability window to ~5.4 V vs Li/Li+, and suppresses solvent decomposition. Physical confinement and chemical binding within MOF channels significantly increase solvent and salt decomposition temperatures, eliminate flammability, and improve safety at elevated temperatures. The flexible MOF-based film maintains better electrode contact than brittle solid electrolytes, while the greatly reduced amount of mobile solvent lowers reactivity at interfaces. Consequently, CEI formation on high-voltage NCM-811 is minimized (essentially CEI-free surface), and dendritic growth on Li metal is strongly suppressed, enhancing Coulombic efficiency and cycling stability. During operation, a fraction of the confined electrolyte (physically confined) migrates to wet the cathode interior, ensuring ionic transport through thick electrodes, while the chemically coordinated fraction remains in the MOF, maintaining persistent sub-nanoconfinement effects over cycling. These synergistic mechanisms enable unprecedented pouch-cell performance at 90 °C and tolerance to mechanical damage (bending/cutting), demonstrating a viable pathway to safe, high-energy LMBs under harsh conditions.

This work demonstrates a MOF-based quasi-solid electrolyte that confines trace amounts of carbonate electrolyte within 6.5 Å channels, producing a nonflammable, thermally robust, and electrochemically stable medium for high-voltage LMBs. By combining physical sub-nanoconfinement and chemical coordination, the electrolyte attains an extended stability window (~5.4 V vs Li/Li+), elevated decomposition temperatures, and a highly aggregated solvation structure that minimizes interfacial side reactions. Pouch cells with high-loading NCM-811 cathodes achieve outstanding long-term stability at 90 °C (~171 mAh g-1 after 300 cycles, ~89% retention) and maintain high capacity after bending and cutting, far outperforming conventional liquid-electrolyte counterparts. The approach offers a promising route to safe, high-energy-density LIBs/LMBs operable under extreme conditions. Future work could explore other MOF hosts and electrolytes, quantify long-term electrolyte redistribution/consumption, optimize film processing and scale-up, and evaluate compatibility with diverse cathode/anode chemistries.

Related Publications

Explore these studies to deepen your understanding of the subject.