Chemistry

A practical concept for catalytic carbonylations using carbon dioxide

R. Sang, Y. Hu, et al.

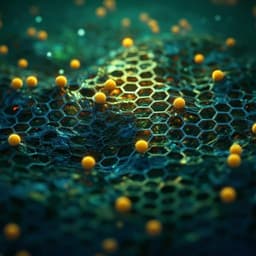

This innovative research by Rui Sang, Yuya Hu, Rauf Razzaq, Guillaume Mollaert, Hanan Atia, Ursula Bentrup, Muhammad Sharif, Helfried Neumann, Henrik Junge, Ralf Jackstell, Bert U. W. Maes, and Matthias Beller reveals a two-step cascade process using CO2 and H2 for catalysis, generating CO with remarkable selectivity and enabling the production of aldehydes, esters, and amides in high yields, presenting a safe and eco-friendly alternative in organic chemistry.

Playback language: English

Related Publications

Explore these studies to deepen your understanding of the subject.