Chemistry

A corrosion inhibiting layer to tackle the irreversible lithium loss in lithium metal batteries

C. Jin, Y. Huang, et al.

Rechargeable batteries underpin electrification but lithium (Li) metal anodes still face severe challenges tied to irreversible Li loss from dendrite growth, inactive Li accumulation, and unstable interfaces. Corrosion—chemical and electrochemical oxidation of Li by electrolyte without external polarization—drives self-discharge and capacity fade. Since 1979, the solid-electrolyte interphase (SEI) has been recognized as a corrosion product layer at the Li/electrolyte interface, whose composition, structure, and evolution (swelling, dissolution, breakage, reformation) govern interfacial stability. Recent studies have verified SEI dissolution in alkali-metal batteries, repeatedly exposing fresh Li to electrolyte and promoting continuous parasitic reactions and SEI regrowth. Galvanic coupling (e.g., Li/Cu, pit/passivated regions) can exacerbate electrochemical corrosion. Despite efforts to engineer SEI via electrolyte formulations and artificial coatings, lifetimes remain insufficient due to limited understanding of corrosion science and its coupling to SEI dynamics. This work quantitatively monitors Li corrosion and SEI progression using electrochemical protocols and cryo-electron microscopy, establishes the positive correlation between SEI dissolution and continuous Li corrosion, and proposes a corrosion-shielding artificial passivation layer composed of low-solubility polymer and metal fluoride to suppress Li loss and extend battery lifespans.

Prior literature identifies SEI as a passivating yet dynamic film whose dissolution and reformation impact Li anode stability. Cui, Zhang and co-workers recently validated SEI dissolution in alkali metal systems, revealing cycles of swelling, dissolution, breakage, and reformation that expose fresh Li to electrolyte. Corrosion can also be aggravated by localized galvanic couples between dissimilar metals (e.g., Li/Cu) or regions (corroded pits vs. passivated areas). Numerous strategies aim to stabilize SEI and mitigate corrosion, including fluorinated solvents/additives (e.g., FEC) and artificial interphases (nitrides, carbons, self-assembled monolayers, polymer-inorganic composites). However, complete elimination of corrosion-induced Li loss remains challenging, highlighting the need to clarify the correlation between SEI progression and Li corrosion. Insights from corrosion science of structural metals inform the importance of passivation layer composition, structure, morphology, solubility, and mechanical/chemical stability.

Corrosion and SEI dissolution quantification: Li||Cu 2032 coin cells were used. To quantify corrosion, 1.0 mAh cm⁻² Li was plated on Cu, the cell rested for 0, 5, 15, 50, 300, or 500 h, then Li was fully stripped. Capacity loss without rest (initial SEI formation) was measured and subsequent additional loss was attributed to chemical/electrochemical corrosion during rest. To quantify SEI dissolution without Li deposition, Li||Cu cells were cycled between 2.0–0.05 V vs Li/Li⁺ for 5 cycles to form SEI, then paused for 50, 30, 15, and 5 h; extra reductive capacity upon resuming indicated SEI dissolution. Electrolytes tested included 1.0 M LiTFSI in DOL/DME (1:1 v/v) with and without 1.0 wt% LiNO₃, 1.0 M LiPF₆ in EC/DMC/DEC (1:1:1 v/v/v), 1.0 M LiPF₆ in EC/EMC/DEC (1:1:1 v/v/v) with 1.0 wt% FEC, and 1.0 M LiPF₆ in FEC/DMC (1:4 v/v). Electrolyte volume: 50 µL. Artificial passivation layer fabrication: A PVDF/metal fluoride (MFₓ; LiF, NaF, MgF₂, AlF₃, ZnF₂, LaF₃, CaF₂) slurry in NMP (fluoride:PVDF:NMP = 1:2:40 by weight) was mixed, brushed onto Cu or Li foils (~14 µL cm⁻²), and dried at 50 °C in a glovebox/dry room. Mass loading ~1.1 mg cm⁻²; fluoride content ~30 wt%. MgF₂ (low solubility, lithiophilic) was the prototype filler; optimized at 30 wt%. The resulting uniform layer on Li was ~25 µm thick. Samples included bare Li, PVDF-coated Li, and MgF₂@PVDF-coated Li, as well as corresponding coatings on Cu current collectors. Characterization: SEM (surface and cross-section), EDS elemental mapping, XRD (identifying Li and MgF₂ phases), FTIR (PVDF α and β phases at ~762 and 839 cm⁻¹), XPS (C 1s, O 1s, F 1s, Mg 2p; LiF signature), cryo-TEM/HRTEM to visualize SEI dissolution and coated interfaces, and EELS mapping of multilayered interphases. Ionic conductivity of swollen coatings measured (~6 × 10⁻⁶ S cm⁻¹ at 25 °C for MgF₂@PVDF). Electrochemical impedance spectroscopy (EIS) and Tafel analysis (from CV, 1 mV s⁻¹; -25 to -50 mV polarization) provided interfacial kinetics and exchange current densities. Cell testing: Li||Cu CE tests at 1.0 mA cm⁻² (and higher currents) compared bare Cu, PVDF-Cu, and MFₓ@PVDF-Cu (notably MgF₂@PVDF) electrodes. Li||Li symmetric cells were formed by pre-depositing Li (10.0 mAh cm⁻²) on Cu and cycling at sequential current densities (1.0–5.0 mA cm⁻²). Full cells paired MgF₂@PVDF-Li or bare Li with LiFePO₄ cathodes (7.6 mg cm⁻², ~1.3 mAh cm⁻²), electrolyte 1.0 M LiTFSI in DOL/DME (1:1) with 1.0 wt% LiNO₃, Celgard 2400 separator. Rate capability tested at 0.13–13 mA cm⁻²; long-term cycling at 1.3 mA cm⁻². Pouch cells: 0.5 Ah Li||LiFePO₄ with 2.3 mAh cm⁻² cathode loading, N/P = 4.3, and Li||NCM523 (3.2 mAh cm⁻²) using 1.0 M LiPF₆ in FEC/DMC (1:4 v/v). All tests at 25 °C in a controlled chamber.

- SEI dissolution correlates positively with continuous Li corrosion. Electrochemical protocols showed increasing capacity loss with longer rest times due to corrosion; initial SEI formation consumed ~66 µAh (no rest). Bare cells exhibited capacity loss of ~125 µAh and CE ~89% after 50 h rest; ~170 µAh and CE ~85% after 500 h.

- Direct evidence of SEI dissolution: SEI shrank after soaking; post-soak SEI enriched in inorganic Li salts with fewer polymeric components; dissolved species collected from DOL/DME contained amorphous polymers and some crystalline Li salts. These observations confirm preferential dissolution of organic SEI and repeated exposure of fresh Li.

- Artificial passivation layer (MgF₂@PVDF) suppressed corrosion: After 50 h rest, capacity loss reduced to ~33 µAh (≈74% reduction vs. bare). Over 500 h, loss increased modestly to ~84 µAh. CE with MgF₂@PVDF remained >92% across rest times.

- Interfacial kinetics: Incorporating fluoride raised the swollen film ionic conductivity to ~6 × 10⁻⁶ S cm⁻¹ (25 °C), with slightly increased cell impedance but higher exchange current densities (0.1–0.3 mA cm⁻²), indicating faster Li⁺ transport.

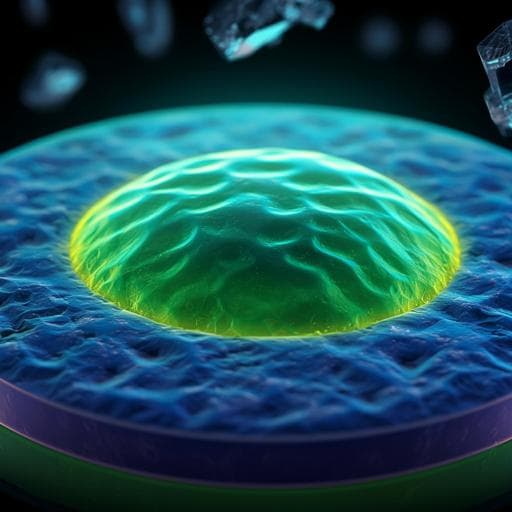

- Interphase structure: Cryo-TEM revealed a double-layered SEI on coated Li: an outer amorphous polymeric PVDF-rich layer inhibiting corrosion, and an inner inorganic layer (Mg, LiMg, Li₂O, LiOH) facilitating ion transport. Coated deposits showed no corrosion after rest; uncoated formed thick, crystalline SEI (e.g., Li₂O) due to corrosion-driven SEI growth.

- Li||Cu CE and morphology: MgF₂@PVDF-Cu achieved an average CE of 96.2% over >500 cycles at 1.0 mA cm⁻², outperforming bare Cu and PVDF-Cu (which reached 94.2% at cycle 297). At higher currents (3.0 and 5.0 mA cm⁻²), improvements persisted. SEM showed uniform Li deposition on MgF₂@PVDF-Cu versus dendritic growth on bare Cu. Coated deposits retained integrity after electrolyte soaking, evidencing anticorrosive function. Coatings with MgF₂, AlF₃, and ZnF₂ reduced nucleation and plating/stripping overpotentials, reflecting enhanced lithiophilicity (LiF and Li–Mg alloy formation).

- Li||Li symmetric stability: Coated electrodes exhibited extended lifetimes; MgF₂@PVDF delivered up to 1700 h operation with low voltage hysteresis (e.g., 22.9–62.8 mV across 1.0–5.0 mA cm⁻² sequences), compared to ~190 h for bare Cu-derived electrodes.

- Full-cell performance with LiFePO₄: MgF₂@PVDF-Li enabled higher capacities and lower overpotentials across rates of 0.13–13 mA cm⁻² (e.g., ~166, 164, 156, 142, 127, 99 mAh g⁻¹ at 0.13–6.5 mA cm⁻²; stable operation even at 13 mA cm⁻²), whereas bare Li struggled at high rates. Long-term cycling at 1.3 mA cm⁻² retained ~80% capacity with CE >96% over ~1500 cycles.

- Pouch cells: A 0.5 Ah Li||LiFePO₄ pouch cell with MgF₂@PVDF-Li showed ~77% capacity retention after 70 cycles at 0.46 mA cm⁻² charge / 1.15 mA cm⁻² discharge, approximately twice the stability of the control. The approach translated to NCM523-based cells as well.

- Quantified corrosion-rate reduction: Li corrosion rate reduced by ~74% (0.66 vs 2.5 µAh h⁻¹), enabling prolonged operation and improved Li utilization.

By explicitly linking SEI dissolution to ongoing chemical and electrochemical Li corrosion, the study clarifies a critical degradation pathway in Li metal batteries. Dissolution of organic-rich SEI components exposes fresh, highly reducing Li to electrolyte, driving parasitic reactions, SEI regrowth, and capacity loss. The designed artificial passivation layer addresses this by combining a low-solubility PVDF matrix that resists swelling/solvation and blocks electron tunneling, with embedded metal fluorides that react to form LiF and lithiophilic Li–M species (e.g., Li–Mg). This dual-function interphase simultaneously suppresses corrosion and enhances Li⁺ transport and deposition uniformity. Electrochemical metrics (reduced capacity loss, sustained high CE, increased exchange current density, reduced overpotentials, low hysteresis) and cryo-TEM/EELS evidence (stable double-layer interphase) support the mechanism. The improvements translate from half-cells to full coin cells and ampere-hour-scale pouch cells with both LFP and NCM523 cathodes, underscoring relevance to practical systems. Overall, mitigating SEI dissolution via an anticorrosion, ion-conductive artificial layer directly addresses the research question of reducing irreversible Li loss and extends battery lifetime and rate capability.

The work establishes SEI dissolution as a key driver of continuous Li corrosion and irreversible Li loss in Li metal batteries, quantifying their correlation via tailored electrochemical protocols and cryo-EM. A practical strategy—an artificial passivation layer composed of low-solubility PVDF and metal fluorides (exemplified by MgF₂@PVDF)—reduces Li corrosion by ~74%, forms a robust double-layer interphase (polymeric outer, inorganic inner), improves interfacial kinetics, and guides uniform Li deposition. Consequently, Li||Cu and Li||Li cells exhibit high CE and prolonged stability, Li||LiFePO₄ coin cells sustain ~80% capacity over ~1500 cycles with CE >96%, and 0.5 Ah pouch cells demonstrate markedly improved retention. The approach is extendable to other reactive metal anodes (Na, K, Zn). Future work should optimize coating thickness/composition, integration with high-loading cathodes under lean electrolyte and low N/P ratios, and long-term stability across diverse electrolytes and temperatures.

While the artificial passivation layer substantially suppresses Li corrosion and improves cell longevity, the authors note that practical application in real cells requires further optimization and development. The pouch-cell demonstrations are preliminary (e.g., 70-cycle window), and broader validation under stricter practical conditions (lean electrolyte, lower N/P, high areal capacities, varied temperatures) remains to be fully established.

Related Publications

Explore these studies to deepen your understanding of the subject.